MAGAZINE No 123 AUTUMN 2010

The Historic Specials day was

well attended as usual, and although I felt there were slightly fewer cars

there than in the past, the standard has certainly risen. It was especially

nice to see Les Brown and his GT (see inside for its rebuild story); it is a

testimony to his skills that he completed his 374 mile journey without

problems, apart from some discomfort perhaps.

TONY STANTONS NEWS PAGE

CLASSIC CAR SHOW NEC

12th, 13th and 14th November 2010

It is with regret I have to inform club members that

your club application for a stand at this year's show has been unsuccessful. I

am however looking for a tidy original Olympic Phase 1 to display on the

Fairthorpe Sports Car Club stand and material/display boards to celebrate the

50th anniversary of the Olympic.

PLEASE contact tony-stanton@fsmail.net

Olympic and Owner from the past discovered (a)

On the 14th Aug the club received

the following message via the guest book on the website,

Hi There,

I would like to let you know that my Uncle owned a light

blue Rochdale Olympic, back around 1971. He bought it in Toronto, Ontario,

Canada. Then moved in with us in Kitchener. I was about 9 years old. He used to

take me out for a donut and hot-chocolate at Tim-Hortons. Back then there was

not much traffic in town so he would put me on his lap and let me steer. It is

still one of my fondest memories of child-hood, sadly my Uncle past away a

couple of years ago. I grew to love cars. While my profession for the last 17

years has been with Audi, I still have a soft spot and enjoy the small British

sports cars. I found this site by Googling the Rochdale Olympic. It is sure

nice to see an owners club and that the memories live on as I was very close with

my Uncle Eric.

Thanks! Kevin Leeder

Kitchener, Ontario, Canada.

I contacted Kevin for more

details; his reply is as follows,

Hi Tony, 18-08-2010

I don't know a lot, because I was

only 9 or 10 years old at the time. My Uncle's full name is

Eric Wayne Leeder. Because he lived with us, his address

on the ownership should have been Forest Glen Cresent, Kitchener Ontario,

Canada. I contacted my father while writing this email. He thinks Eric had the

car already when he moved in with us. We both think that he bought the car in

Toronto area.

He was living at Bolger Place, Rexdale which is in Toronto,

which was my grandpa's house. The car was a light blue when he had it, but I

think I remember some paint was chipped off and was a darker blue underneath.

My dad doesn't think he has a picture, but he will look for me, also I will try

and contact my aunt who might have some more info or a picture. That is about

all I know.

A short laugh/memory. It was in the winter sometime

first thing in the morning and it was cold. It must have rained the night

before and the doors were frozen. My dad had to move my uncle's car, I remember

vividly (I am laughing as I write this) my uncle said "Bill be careful

pulling on the door cause the handle will come off." It seemed like only

a minute later my dad comes in with the door handle, and my uncle saying I

told you. My dad said what a cheap car, which my Uncle responded, it is made

of fibreglass. I now have tears in my eyes I can't stop laughing so hard. Anyways

I just love these cars and would love to own one. Sincerely Kevin

This was a Phase 1 imported into Toronto in 1962 as a

bodyshell kit by Ian Keith who sold it to Eric Leeder who later sold it in 1974

to Dr John Somerville who wrote a few articles on the car in the club magazines

in the 1980's.

John sold the car in 2003 to Stephen Szikora from Guelph,

Ontario. The car has been in the Toronto area all of its 48years and as we had

not heard from Stephen since 2005 I e-mailed to see if he still had the car.

His reply is below.

Hi Tony, 19-08-2010

As requested, a picture is attached. No, the car is not

running. It is going to be a long-term project. It currently is sitting without

a drivetrain or interior in it. The original Riley 1.5 running gear had been

replaced with the engine, transmission and rear axle from an Austin Marina S

and the front torsion bar suspension replaced with the crossmember and coil

spring set up out of a Vauxhaul Viva. I obtained a Riley 1.5 and have removed

the complete drivetrain and suspension from the donor to put the Rochdale back

into original Phase 1 spec.

The Rochdale is sitting in the driveway while my single-car

garage entertains my other toy, a '73 Jensen Healey that is in much better

condition. Every now and then I look at the Lotus engine with dual Webers and

wonder what it would be like in the Rochdale!

Thanks for forwarding me the message from Kevin. I'll

contact him and send him the picture as well as a scan from the issue 96 of the

club magazine showing a picture of the car with the owners prior and subsequent

to his uncle and a little history on the car.

Stephen

MDP

648 resting in Canada in 2010

Olympic and Owner from the past discovered (b)

I received the following e-mail

via James Farrington.

07-06-2010

Came across the Rochdale

Owners Club web forum by accident.

Was doing a google search for

Neville Hodkin who apparently owned a lightweight Olympic I sailed/race yachts with

Neville for 6 years until 2005 and was aware he raced cars before taking up

racing yachts but had no idea he had owned an Olympic.

This piqued my curiosity as

the father (George Linsley) of my best friend from school (Kevin Linsley) owned

an Olympic with a Riley 1500 engine. I have fond memories of being driven to

school in the Olympic in 1974. After a few years inactivity the car was sold

(probably around 1984) to another friend from school Saleem Hafizullah who I

believe is a policeman in the Bolton/North Manchester area.

Hope this info is of use -

still in touch with the Linsleys and hopefully shortly with Neville - I haven't

heard from him for a while and as he's 76 one always worries. Regards Jon

Holdsworth

We have in the factory ledger a Phase 1 supplied to a

George Linsley of Cabus Nook Lane, Cabus, Garstang, Lancs in November 1961, but

no registration number or later owners. I emailed Jon, but he had no more

information, but he contacted his old friend Kevin who asked his father to

contact me.

Dear Mr Stanton, 22-06-2010

My son, Kevin, has passed on the various E-mails

about the car I owned all those years ago. The registration was 727 XTC. I am

willing to talk about it, but fear I have very little to say other than I

thoroughly enjoyed building it and running it for so many years. Eventually

domesticity and the availability of a 'company car' necessitated its departure.

I have a photograph but currently I also have a computer problem and cannot

apparently either scan it nor enter it from a re-photograph which I have taken

so I will try to get this fixed and then send it later. or, if you wish to give

me an address, I can post a 'hard copy'.

I was at Cabus Nook Lane,

Garstang for some time (in fact I designed it and had it built for me) but I

cannot remember any more about when or how I sold the car - sorry.

Just in case it may be of some slight amusement I can

recall a few stories about the car. When I bought it I went to collect it on a

low trailer pulled by a Ford Transit owned and driven by a friend. Of course

this meant that, from even a short distance it looked like a 'sports car' very

closely following the Transit even though there was of course, at that stage,

no 'works' in it, nor even wheels. The sight, however, was clearly too much

for one impatient driver at a roundabout who just wasn't going to have the

'sports car' cut in so he tried to get between Transit and Rochdale. You can

imagine his reaction when he discovered, very late in the day, that there was no

driver and it simply wasn't going to stop to let him in!

The other memorable item was that I discovered that

in deep snow (which we seemed to have more of in those days) the almost

complete 'undertray' acted like a toboggan, with at least some 'steering' from

the wheels, so going downhill was great. Unfortunately, there was no traction

whatever when we came to rest at the bottom of a considerable dip, since there

was over a foot of quite soft snow beneath the wheels, the car sitting on its

'undertray' which spread the load. When I got out I discovered just how deep

the snow really was as it wouldn't support me!

I am delighted to know there are still some Rochdales

about. I always felt it was a pity they couldn't develop what I believe was a

wonderful idea of a 'monocoque' egg-shaped body into a slightly larger version.

Regards,

George Linsley.

George driving 727 XTC in 1962

I also traced Saleem Hafizullah through this advert in a

Fairthorpe magazine of October 1981: - ROCHDALE OLYMPIC phase one,

rare car. Complete but needs working on. Spare engine and wiring loom. Offers

or swop. Tel: Bolton.

He was only 16 in 1980 when he bought the car off

George with a lot of work to do including a seized engine. He found he did not

have the know how to rebuild it so sold the car in 1981 to our ex chairperson

Roger Coupe who stripped it and used the body shell standing upright on its

nose at the 1984 Belle Vue Classic Car Show. I have traced the car through 7

more owners and the car is alive and well with a registration number change and

in the capable hands of Richard Disbrow in Dorset.

Olympic and Owner from the past discovered (c)

I also received this e-mail from

James Farrington (he keeps me busy)

Hi Tony, 14-07-2010

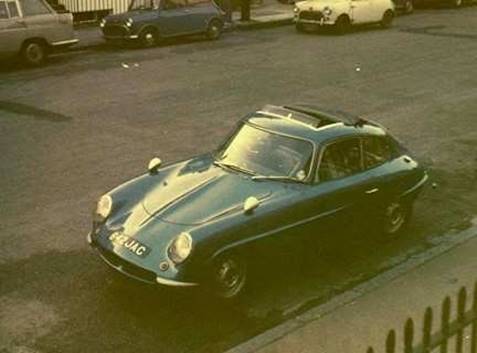

I hope you are well? I've just had a phone call from a

Professor Norburn. He said he was looking around the internet and came across

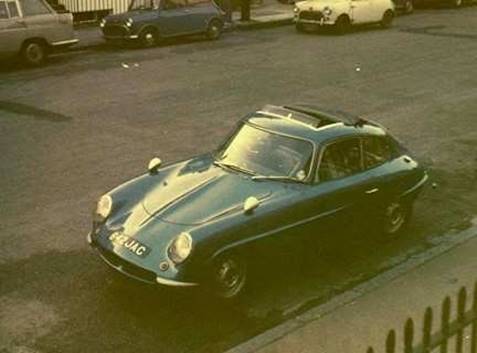

the Phase 2 for sale on Sussex County Sports Cars, 624 JAC (this is the ex-Fred

Blackmore car we have had on the stand at the NEC and at Bristol Show)

He said he used to own that car between 1970-1975 and

had it re-built by Tickner Brothers who were a well-known car specialist at the

time. He also said it was blue when he had it and had a sunroof. The gelcoat

was red but the engine bay gelcoat was dark green. I was at work so didn't get

the chance to talk to him much but he said he would be delighted to talk more

about it. Can I hand this one over to you?

As an added teaser he also said

he once owned a Rochdale GT, couldn't remember the number plate but said he

should have pictures of it somewhere (8069 ML).

Many thanks James

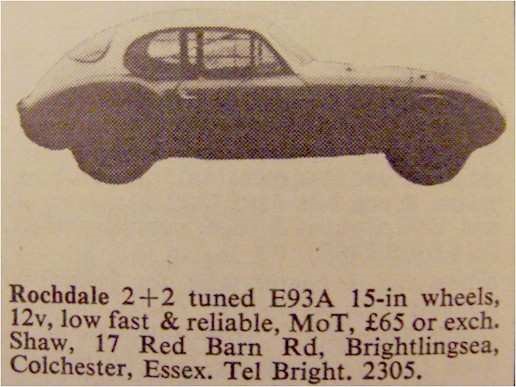

I phoned Professor Norburn. He has recently retired after

16 years as the Director of the Imperial College Management School. He sent me

some photographs and said he enjoyed his time with a GT and 5 years with an

Olympic. He sold the Olympic to his brother in law Graham Birley who had the

car for 10 years. I found an advert from Exchange & Mart from the time he was

looking for an Olympic.

22 Oct 1970 E&M

Wanted Rochdale Olympic, ideally Phase II but would

consider good Phase 1. Norburn, 9 Rees Street, London N1.

642

JAC parked in London in 1971

Olympic and Owner from the past discovered (d)

I also received this e-mail from

James Farrington (he keeps me very busy)

Hi Tony, 15-07-2010

Just thought I'd let you know of another lead my Father in

Law discovered today of a previous Rochdale Olympic Owner. Please can you have

a look in your files to see if you recognise the car or name and if not I can

chase it up some more?

A well-known member of the Bristol Owners Club who

wrote the book, Bristol Cars: a very British Story called Christopher Balfour

used to own a Rochdale Olympic. He said it was a very early one and remembered

the fire at the factory after he bought it. He said it was dark silver in

colour and it used to be displayed at various shows by Rochdale Motor Panels

prior to him colleting it. He said the registration was four digits followed by

the letters DF. It was

also Riley 1.5 engined. If you already know of this

owner then let me know, Regards James

I know this Phase 1 registration 1523 DF very well as

it belonged from 1978 to 1990 to a long time good friend of mine (Mr Rochdale)

Stan Hanks and currently resides with Roz King in Salisbury. The factory ledger

shows the car was ordered Oct 1961, the fire was Feb 1961, and he was charged

£30 for spraying the car Grey. I do not know when the car was collected, but he

paid the main cheque Feb 1962, but then another one on June 1962 and the car

was not registered till Sept 1962, so it may have been used at shows, it was

definitely on the stand at the Racing Car Show in January 1962

I contacted Christopher Balfour and it appears that

in 1961/1962 he was in talks with Harry and Frank about investing in Rochdale

Motor Panels and travelled to Rochdale for meetings and stayed with Richard and

Hilary Parker in their cottage at Hollingworth Lake. He sent me a photograph of

the Olympic taken at his home on the day he collected it from Rochdale. I also

found an advert in Motor Sport July 1963 when he sold the car: -

ROCHDALE OLYMPIC. Metallic grey. Much effort given to

developing this car. Still not perfect but performs with distinction. Owner no

longer able to give the deserved attention. Approx 6000 miles. Suggest £545.

Box No. N907

1523 DF after collection from

Rochdale.

PS I think this is now the 5th ex

Rochdale owner James father in law David has discovered in the Bristol Owners

Club!

And a little note to end on. Sign for the rear of

your classic car: -

"The parts falling off this

vehicle are of the finest British craftsmanship".

The Pros and Cons of Rubber and Plastic Suspension Bushes

Tony Stanton

I

recently had to replace 8 large rubber suspension bushes on DUFFY (there are

also 20 small rubber suspension bushes which did not require changing). Because

initially I had no idea what car the originals were off I had considered fitting

polyurethane ones till I read the following details.

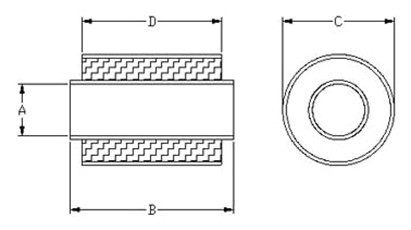

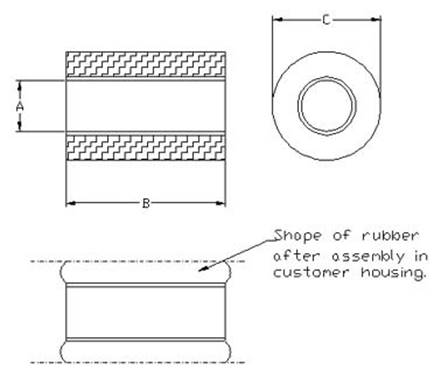

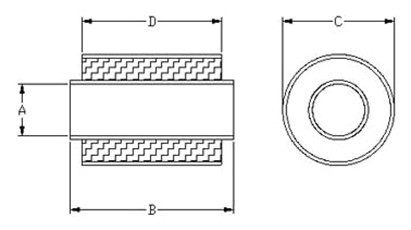

Torsion Bush

A wide range

of standard versions are available providing characteristics to suit diverse

applications. They are commonly used in automotive applications for suspension

system linkages or leaf spring mounting, where some degree of movement is

desirable. This bush design provides for displacement in a combination of

radial, axial, torsional or conical loadings (see diagrams  below)

below)

Bushes are placed at the pivot

points for any of the following reasons:

a)

Smooth and predictable movement without the wear associated with

solid metal bushes. No surface to surface sliding motion for any required

motion.

b)

Vibration isolation - rubber bushes reduce road noise in

automotive applications whilst absorbing impact loads.

c)

Deflection under load - when engineered into a system, this

deflection can allow the linkage freedom of movement. If deflection is not

accommodated within the torsion bush, stresses may be transferred to other

mechanical components.

d)

Modern suspension systems are designed so that the bush

deflection does not seriously impact alignment, allowing for vibration

isolation whilst maintaining the steering geometry.

Torsion Bush

Type BB:

Torsion Bush

Type BB:

This bush comprises inner & outer tubes in

which the rubber is chemically bonded to both tubes allowing applications

requiring loading in all possible directions and combinations (BB = double

bonded).

Torsion Bush Type

TB

Torsion Bush Type

TB

With the

addition of an intermediate tube which is again chemically bonded in place

during the moulding & vulcanisation process. This type of bush is suitable

for the highest loads (TB = triple bonded)

Torsion Bush Type

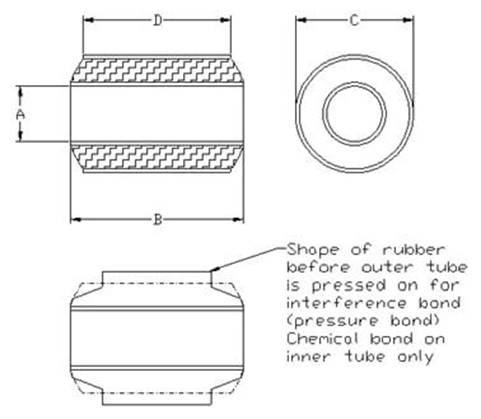

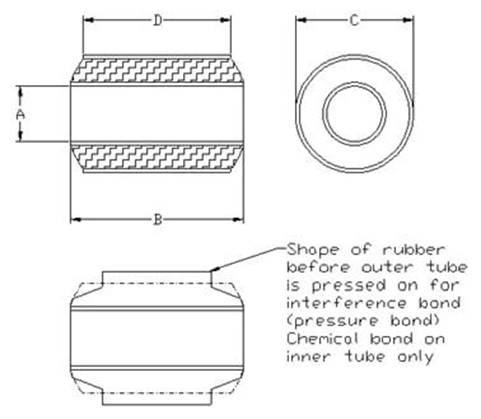

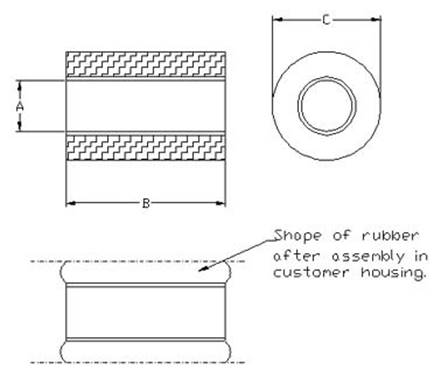

B

Torsion Bush Type

B

This type of bush embodies both chemical bond (inner

tube only) and interference fit. The interference fit provides for

pre-stressing of the rubber making it stiffer for normal radial, conical and

torsional loads. It is not intended for use in high axial loading situations.

One advantage of this bush type is that occasional extreme torsional

overloads can be accommodated since the bush will slip within the outer tube

under these conditions Torsion Bush Type BE:

One advantage of this bush type is that occasional extreme torsional

overloads can be accommodated since the bush will slip within the outer tube

under these conditions Torsion Bush Type BE:

Employing

both chemical bond (inner tube only) and interference fit as for the B type

bush, this version has a chemical bond for the full length of the inner and

tube and a specially shaped rubber section designed to prevent metal to metal

contact under axial overloads.

Torsion Bush Type SAB:

This bush type is designed for use where a machined housing

is available and hence no outer tube is provided. An interference fit provides

the required pre-compression as for the B type bush. This construction is

intended for only light axial loads.

Loading Methods

The degree of displacement for a 2 tube system and

based on a constant elastomer can be designed-in by adjusting the basic

parameters of length plus inner and outer tube diameters as follows:

Radial

This relates to displacement such that the inner tube is

moved towards the outer tube whilst remaining axially parallel to it such that

the thickness of rubber is reduced uniformly on one side. The radial

displacement can be decreased by increasing the projected area (diameter of

inner tube x length of outer tube). This can be facilitated by increasing the

overall length of the bush or by increasing the outside diameter of the inner

tube. When only radial loading is anticipated, these bushes will withstand

significant shock loads in excess of normal rated load for the size (up to 5

times rated loading) However, if

conical loading is anticipated in addition to radial loading, the nominal rated

loading must be reduced. Also if cyclic loading is anticipated, the load

catered for should be at least halved.

Torsional

When one tube is rotated relative to the other whilst

remaining axially parallel, this implies a torsional load. Reducing the

thickness of the elastomer will reduce the angular displacement for a given

torque (increasing the inner tubes outer diameter or decreasing the outer

tubes inner diameter) or by increasing the overall length of the bush. Typically,

the maximum frequency of torsion loading accommodated is 8Hz (480 cycles per

minute) and this would be for small angular movements up to +/-5 For lower

frequencies +/-40 can be accommodated for some bushes where the rubber

thickness allows.

Conical

If an angle is developed between the axis of the two

tubes such that they are no longer parallel, this is a conical load. The

displacement from such loads can be minimised by reducing the thickness of the

elastomer or by increasing the length of the bush as above. Applications should

limit the angular movement such that the thickness of elastomer at the end of

the outer sleeve is not reduced by more than 30%. Clearly, greater conical

movement is provided by a greater thickness of elastomer, which in turn can be

determined by changes in tube diameters.

Axial

When the ends of the tubes are displaced relative to their

no-load position whilst the axes remain parallel, this is an axial load. The

displacement can be reduced by reducing the thickness of the elastomer or by

increasing the length of the bush as above. Design loads should be kept to a

maximum of 10% of the rated radial load.

The deflection parameters can also be modified by

altering the hardness of the elastomer (harder reduces deflection) or by

inserting an intermediate tube which reduces deflection in all directions as

for example in our TB (triple bonded) bush type.

Installation

The outer tube is either clamped in place or is an

interference fit in a machined housing requiring insertion using a mechanical

or hydraulic press. The inner tube is typically held in place by a clamping

bolt which is tightened to sufficient torque to prevent the inner tube from

rotating in use under the forces likely to be experienced.

Press Fit Tolerances on Bores

In most applications bushes are intended to be a

press fit in a bore. In this case the following bore tolerances should be

applied: The bush diameter should be taken as its nominal size

mid-tolerance.

Note: where the bush is to be

inserted into a rolled spring eye, the interference is greater is greater due

to the yielding of the spring eye.

|

Outside

diameter of bush (mm)

|

Bore limits from nominal bush O/D

|

Rolled

Spring eye Bore

|

SAB Style Bushes

|

|

6 to 23

|

-0.04 / -0.06

|

-0.25 / -0.50

|

-0.25/ - 0.35

|

|

24 to 40

|

-0.05 / -0.08

|

-0.40 / -0.70

|

-1.00 / -1.10

|

|

41 to 50

|

-0.06 / -0.09

|

-0.9 / -1.10

|

-1.50 / -1.60

|

|

51 to 70

|

-0.08 / -0.0.10

|

-1.00 / -1.40

|

-1.70 / -1.80

|

For SAB style bushes without the outer steel tube, the

degree of interference is also much greater. This provides for security of

installation and also has the effect of stiffening the bush due to the

compression of the rubber during assembly.

Typical application automotive suspension

The torsion bushes on most cars consist of a larger steel

sleeve mounted inside the control arm, with a smaller steel sleeve inside for

the mounting bolt, held in place with rubber which was bonded and vulcanised in

place. The sleeve is fixed into the arm, and the inner tube held tight by the

mounting bolt. As the arm moves, the rubber material gives way to the shear

forces, allowing smooth movement of the arm without any sliding motion or

surface-to-surface friction and hence nothing to wear, squeak or rattle. Most

modern rubber torsion bushes are double bonded (i.e. the rubber is chemically

bonded to both metal surfaces during the curing (vulcanising) of the rubber. In

some cases the outer surface is held in place by creating a significant

interference fit during assembly of the bush. Such bushes are not intended to

slide within the outer sleeve but allow for occasional extreme torsional

overloading of the bush.

Materials:

Inner

& outer tubes are of steel which is zinc plated or Sherardized and clear

or yellow passivated. For the chemical bonding process, the bonded surfaces are

further treated with special purpose priming and bonding agents. To achieve the

required quality and ensure that the surfaces are not contaminated prior to

bonding, the latter operations are under in-house control.

Polyurethane bushes:

Polyurethane bushes have become popular, as they

noticeably stiffen the suspension and are claimed to outlast the OEM rubber

equivalents. The same effects could be accommodated by using harder rubber

compounds or by changing the tube diameters. However, most users do not

understand how torsion bushes are intended to work and how these alternatives

differ in principle and the problems they create. The recent popularity of

polyurethane after-market replacements has drowned out the advantages of the

proven designs, resulting in stiction, binding, squeaking, harshness, and need

for regular greasing.

Polyurethane is used in place of the rubber portion

of the factory bushes. Unlike the rubber bushings, these bushes are not bonded

to an inner and outer sleeve and are sometimes used simply because they are

easier to fit. However, if easy to fit then there is no interference and hence

a loss of stiffness will result. In typical automotive use, movement of the

control arm will cause the internal surfaces of the sleeves and bush to slide

to accommodate the shearing forces. This raises the issues of stiction and

binding, both of which can affect steering predictability under extreme

handling conditions.

Void bushes

Whilst on the

subject of bushes it's worth remembering that the big boys (GM,Ford etc.) spend

literally millions on the design of these little rubber bushes. Some of you may

remember an in phrase back in the early '70s - void bushes. As a result of

their enormous investment to improve passenger comfort Ford realised that they

could tune the frequency response (and absorption) rate of suspension bushes

by moulding in little pockets. If you look at modern day items, you'll notice a

plethora of pockets and bump ridges which go to make the bush soft in normal

use and harder in extreme conditions. Some are even directional in that they

are softer in one direction than another.

Whilst on the

subject of bushes it's worth remembering that the big boys (GM,Ford etc.) spend

literally millions on the design of these little rubber bushes. Some of you may

remember an in phrase back in the early '70s - void bushes. As a result of

their enormous investment to improve passenger comfort Ford realised that they

could tune the frequency response (and absorption) rate of suspension bushes

by moulding in little pockets. If you look at modern day items, you'll notice a

plethora of pockets and bump ridges which go to make the bush soft in normal

use and harder in extreme conditions. Some are even directional in that they

are softer in one direction than another.

As fitted to DUFFY by Richard Parker

My conclusion:

It's my belief that a good, fast road car is a compromise

between good handling when cornering, accelerating and braking and having a

comfortable relaxed ride. It is no good Bill having a car that handles slightly

better than Freds if it is uncomfortable and tiring to drive. Remember cars

designed for race tracks do not make good road cars and vice-versa, so from the

above article I think rubber bushes seem to be more tune able (specially with

void bushes) than polyurethane and therefore a better compromise.

* * * * * * * * * * * * * * * * *

A little comment to end on from

Alan Farrer:

I imagine that poly bushes have become available on the

aftermarket because polyurethane is easier to mould than rubber and they are

usually sold separately from the inner and outer sleeves. Rubber bushes also

requires chemical bonding and therefore close process control. Because there

is sliding contact between the inner sleeve and the poly, the sleeve should be

made from stainless steel to avoid corrosion and consequent wear.

I have fitted poly bushes to several of my Olympics

and have replaced some with rubber for the reasons mentioned above, ie stiction

and squeaking, and also because they can deform permanently under constant load

eg on the rear suspension. I shall use only rubber in my current rebuild.

Boys will be boys - but this was the

real thing

Derek Argyles GT40 Memories

The

phone rings, it's Jenks. Doing anything tomorrow morning? Not particularly,

why, anything on? We've got a GT40 on test, should I pick you up about

10.30? Not 'arf Jenks, see you tomorrow, thanks.

The

roar of the 4.7 litre GT40 made its presence felt in our Close bang on time.

Forty inches tall hadn't meant too much to me until I was about to enter the

car when I realised just how low the roofline was and how much I would need to

duck to enter. For tiny Jenks the car was made for him. As I buckled up in the

reclining vented seat I felt extremely comfortable and could readily see the

need for such comfort when cars of this ilk were competing in races lasting as long

as the twenty-four hour Le Mans event.

Making

our way along the A30 from Camberley towards Basingstoke I was surprised how

smooth was the ride of this sporting car. I had expected a much stiffer ride

and, in commenting to Jenks on this point, he said that this was only the

cooking version of the GT40 hence the sound deadening and the carpets. With

about 90 fewer horses there was almost certainly softer suspension fitted as

well.

There

was one occasion as we drove along part of the A30 that had single carriageway

where we came upon a slowish A30 saloon. After a while an opportunity occurred

for us to overtake the little Austin and as we passed and cut back in on the

over-run because of another car ahead, flames poured out of our exhaust pipes.

I hope the driver wasn't too put off in the enjoyment of his Sunday drive.

More

slow-moving Sunday drivers led us to turn south along the A339 as we reached

the Basingstoke outskirts. Having felt some of the power of this engine along

the A30 I craved for more and asked Jenks if he could demonstrate for me a

0-100-0 blast. We selected a suitable strip along the road giving us a perfect

view forwards and backwards and Jenks then floored the throttle. Within seconds

I yelled One hundred and then Jenks very quickly brought the car to a halt.

It was all over in a moment, my mind had to catch up with what I had just

experienced. The acceleration has been fierce but not violent, the power made

the car surge forward progressively with only one barely noticed, ultra-quick

gear change. Almost more impressive were the brakes. In those days most popular

cars if braked incredibly hard would cause the cars nose to dip violently and

the vehicle would become unstable. The driver would realise that the belts were

doing a fine job of not putting him through the screen but with the GT40 one

was in a different world. Probably because of anti-dive front suspension the

very powerful brakes of the GT40 simply caused the car to stop in a perfectly

level attitude with no drama, no skittishness and a feeling of total control

and safety. Again my senses had to catch up; I had never experienced such

performance and I realised that if I ever had the opportunity of driving a

really potent car I wouldn't just jump in and drive off but would prepare

myself for my reactions that would have to be much sharper.

We came

to Lasham and turned in to the airfield where we spent a little time watching

many beautiful gliders silently drifting above us in total contrast to the fire

and fury of the Ford. On leaving the airfield we made our way towards the

Golden Pot and down towards South Warnborough and Odiham aerodrome. Along this

narrow stretch of gently winding road and knowing that there were no side

turnings, Jenks yelled Hold tight and accelerated to 144 mph before backing

off. Phew, what'll she do Jenks?. About 165 as this is only the road

version. After this we decided a pint would go down nicely and stopped in the

deserted Odiham High Street. Jenks switched off, total peace and quiet except for

the pings of the cooling exhaust system. As we emerged from the car, totally

out of nowhere appeared two young lads and looking at Jenks and myself said in

total awe Wow, Batman and Robin.

EARLY ROCHDALES

Now, I do not want to sound like

an incorrectly downloaded iPOD song (a broken record to the older generation)

but where have these past few months gone? It only feels like last week that I

was writing this very same article declaring my lack of time and busy work

schedule and here I am again trying to cram an Early Rochdale related article

into the only quality time I get, although I do find it is quite peaceful in

the toilet.

Having spoken to Tony Stanton

recently I realise we are both having the same problem, the problem being

having so many pokers in the fire, sometimes they all need taking out at

once. The amount of leads, half completed history trails and contacts to talk

to are slowly mounting up and my email inbox contains more letters than you'd

find in a Royal Mail sorting depot. I will attempt to deliver an informative

article for your perusal though.

This past few months has been a

roller coaster ride for me in the world of Early Rochdales, I say roller

coaster as I'm on track to need a bigger garage, my bank balance has dipped

and my wife is going round the bend. Let me explain........

Mark VI

In the last magazine I showed you

the pictures of the Mark VI Rochdale bodyshell that I had purchased and hinted

I might be reuniting it with the original chassis; well the two are now well

and truly back together and waiting to be put back to their former glory. It

started like this:

Having a daily glance at the

Rochdale Owners Club website forum I noticed an entry from

Keith Nicholson, who I partly

blame/thank for the purchase of the Mark VI, stating there is a Paramount

roadster on Ebay, may have been Rochdale bodied at one stage according to the

description.

It was following this that I

contacted the previous owner of this once Mark VI bodied Paramount chassis

advertised on Ebay, Brian Parodi. Brian informed me he had big plans for the

chassis and created an ash frame to recreate the original lines of the

Paramount and wanted to use the Mark VI shell for projects further down the

line. Unfortunately, other projects took over so the chassis had to go and he

sold it at auction a while back. Brian did still have the bodyshell in his

garage though and was prepared to sell it. Deal done I went up to collect it

that weekend.

Although the sentimental side of me

wanted to reunite this bodyshell with the chassis for sale on Ebay I was too

late as it had already been sold. I had other plans but decided to telephone

the new owner of the Paramount chassis to get a copy of the history file for my

early Rochdale records, it was at this point he told me he no longer intended

to use it for the fitting of a 4CS Maserati body and offered me first refusal

before he put it back on the market or sold the engine separately. I jumped at

the chance and drove the 20 mile trip across London (3 hours in the Friday

traffic) to have a look, upon seeing it I had to buy it and made the offer,

after all, the kids education allowance could wait a few more years before I

top it up.

Paramount chassis

This particular car is probably

the only Paramount Mark VI to have survived intact having been built originally

on its chassis by Mr I Martin from Kirriemuir. This then changed hands in 1995

being sold to the well-known classic car enthusiast Duncan Rabagliati and

finally resting with Brian Parodi in 2007.

C Type

Now, this is where it gets more

complicated.......

Out of all the Rochdale marques

out there I have always had a passion for the looks of the C Type Rochdale, I

have been trying for months to track one down for sale and have finally got my

hands on an example that comes with added extras, undergrowth. Not quite the

state I imagined my next restoration project but this is a basket case example

of a Buckler-chassied C Type that I can't wait to get my hands dirty on.

I will endeavour to give you more

information in the next magazine as the copy date falls a week short of the

collection date so I will know more then. I will also let you all know how the

marriage counselling is going, now I've spent our rainy day savings on what my

wife calls an expensive plant pot.

1 2

3

7 8

9

13 14

15

19 20

21

Picture numbers as referred to

in text on pages 25,26

4 5

6

10 11

12

16 17

18

22 23

24

Picture numbers as referred to

in text on pages 25,26

VAR 732 in its former glory

American C Type Owner Surfaces

Around 1954/55, the Type C came

on the market. It was normally sold with no internal framework or bulkheads. It

looked a lot like John Coombs' Connaught ALSR; in fact it was alleged to have

been created from the aluminium body of that car (hence the 'C'), when it had

come into the workshop for repairs and had moulds quickly taken off it

overnight.

The shell was one-piece and aimed

at the common wheelbase of 7ft 6in, although it could be modified to fit longer

wheelbases if required, and was priced at pound75. With its deeply scalloped front

wings the styling was very reminiscent of the Aston Martin DB3S.

There was no passenger door cut

as standard and the grille opening was left to the builder; bonnet and bootlid

were supplied cut, flanged and rebated with separate driver's door and inner

wheelarch panels also supplied. With its aerodynamic shape the Type C was often

used for racing and has been known on chassis from Buckler to TVR, including

BSA Scout, Cooper, MG TA, Ford 8, Lister-Bristol and Tojeiro, but it is

believed that only around 40 were sold.

In 2008 we detailed the discovery

of a C-Type that had turned up in America; at the time the contact was made by

someone trying to find out more information to potentially purchase the car.

Fortunately for us the owner of this C Type has now contacted the ROC, he

writes:

Hi, my name is Nick, I have a

Rochdale type C that I purchased 34 years ago. It is on a 1951 MG TD. It was

used for racing in England and it was purchased by a man who went there to work

for his company for 3 years and he saw the unusual car, I think at a race, and

he purchased it and brought it back to the U.S. in 1959. It has 1,800, yes

1,800, miles on it. He gave me a lot of brand new parts still in the original

boxes for it. It has the original Dunlop Racing tires still on it. The body is

solid, but it has some cracks in it, he said from racing. I am trying to get

any and all information I can on this Rochdale type C because I had it in

storage all these years and now I am going to try to restore it. Any help or

information that the Rochdale Owners Club members could offer would be greatly

appreciated. Thank You very much from an OLD CAR loving guy across the seas...

Malcolm McKay writes:

I've been passed your email as I

am Registrar of Early Rochdales for the Rochdale Owners Club - thanks very much

for getting in touch about your C-type.

There are very few surviving

Rochdale C-types - because the bodies were aimed very much at the sports racing

car market, inevitably most of them had a very hard life and fell apart long

ago. So it's great to hear of one that has survived with so little use. We

heard about yours from another MG owner a few years ago, but he never gave us

your contact details so it is really good to make contact at last.

There are some intriguing

similarities between the bodyshell on your car and a C-type shell that was

fitted to one of the first TVR chassis in 1955, using an MG 1250 engine, photo

below. I did wonder if the body could have been taken off the TVR chassis after

the car was taken to USA and put on the MG chassis - it seems very unlikely

that it was built on a left-hand drive chassis in England.

It is great to hear that you will

rebuild the car. I hope you will find it worthwhile to join the Rochdale Owners

Club. If so, we could put you in touch with John Walkington, one of our members

who is just finishing rebuilding his C-type, which he built new in the 1950s

picture of the current restoration progress below.

John Walkingtons C-type under restoration

To the best of my knowledge,

there are five original C-type bodyshells left in the world, including yours.

One is on a Ford Popular chassis, in poor condition and has not been seen for

15 years; another is in very derelict condition on a rusted-out Buckler

chassis; another is/was on an MGTA chassis, stored for 50 years until it

surfaced in 2007 but immediately disappeared to Europe; and the fourth is John

Walkington's. So it's a very rare car. Unfortunately, rarity doesn't always

equate to value, except from a historical interest perspective, but there would

certainly be great rejoicing in the Rochdale Owners Club if you restore yours.

On the Road Again

Les Brown has kindly written the

following informative article on the progress of his Rochdale GT.

Strictly speaking, of course my

GT has been taxed and MOT'd for over a year now, but in spite of satisfying

legal requirements it hasn't really been driveable during that time - there

were far too many loose ends needing tidying up ... and still are. But at least

a round trip to Burford (374 miles) served to highlight some of these, and also

to demonstrate some excellent features of the car. It's an unusual

specification, even for a GT, so perhaps a few words on its background would be

appropriate.

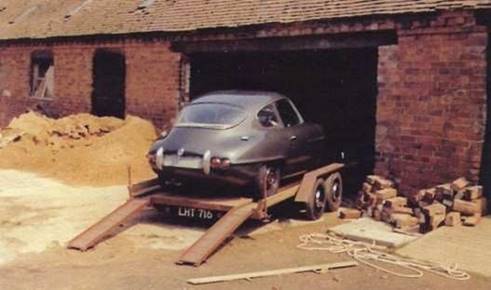

Les Browns GT6-chassied Rochdale GT (before)

The car had been bought in 2003

as a school project, and although far from sparkling had obviously had a

considerable amount of very good work done on it before that time. The car had

been seen at Burford 1992, and its original CSA 390 (I think) number had been

lost, along with its original Ford parentage, long before my tenure. Shame, I

do like to see those old numbers still in use, but on the other hand some bad

experiences with side valve Fords early on meant that they wouldn't tempt me to

use one in a performance car, though I know some can be made to go very well

indeed - if you're determined enough... What was interesting was an extremely

hefty-looking Triumph chassis (it made considerable use of outrigger sections,

welded on to the original) with some very nice suspension attached. Again,

Heralds and the like never really did much for me with rear wheels (and even

front when they approached full lock) to be seen at all sorts of odd angles

which never seemed quite right from a purist's viewpoint. But at least it was

just about in period, with the first Herald appearing in 1959, and while I

doubt that any GTs WERE placed on that chassis before production ended, it was

at least a possibility. And at least this one had avoided the dreaded swing

axles with the much rarer GT6 wishbone arrangement, a little further out of

period at 1968 onwards, but I was quite prepared to forgive this for the sake of

better control of those camber angles.

The rest of the car wasn't quite

so promising. There was no engine or gearbox present, and likewise the interior

of the car was completely empty, with seats, instruments, steering, brake

pedals, even doors missing from the car. Some of these were turned up, and had

clearly been fitted at some stage, and it became apparent that moves towards an

A series motor had been made. I did prefer this unit as it was much more

familiar to me than the obvious Triumph fourcylinder so I decided to go along

with the plan, though whether I would STILL follow the same path with the

benefit of hindsight is another matter. Why no GT6 engine? Well, it's a massive

lump which even Triumph engineers struggled to place under a Spitfire-type

bonnet, and the Rochdale available area is cramped enough as it is. I know GTs

HAVE been put together with this engine, but it's not something to be taken

lightly and must inevitably result in some pretty big bulges towards the front

of the car.

A 1098cc Minor engine was

purchased from a local scrapyard, and completely rebuilt in the school

workshops. I did come to regret this a little, however as I stumbled on a

big-bearing MG version of the same engine at a price I couldn't refuse, but

only after we had done all the work on the Minor unit. Again, the MG is a

little out of period at 1964-66 but is said to be an excellent unit by Midget

aficionados, and actually preferred by some to the later 1275 engine.

With the benefit of such goodies

as 12G295 (Cooper) cylinder head - I know I'm sad to be able to quote such

numbers off the top of my head, but there it is - and twin 1" SUs (my

favourite) this 59 bhp engine is actually more powerful than the 1500cc Ford of

my Olympic and is said to rev very smoothly on its special crankshaft. I

hadn't realised just how far forward all the Triumphs carried their engines,

and the A series was mounted further back to enable the radiator to be squeezed

into the Rochdale bonnet - a VW (Golf?) unit came complete with electric fan.

We made all the engine mounts with the shell off, which seemed to be a good

idea at the time, but subsequently found the A series distributor needing to

occupy the space normally reserved for Triumphs steering column. This one

still hasn't been fully resolved, and results in a driving position (even more)

cramped than normal.

Going through the small photos:

1 A

series engine, actually still a 1098cc Minor unit, although a number of Midget

parts are installed to enable it to fit under the bonnet - the standard cast

manifold had the SU further out, with the exhaust pointing straight at the

chassis.

2 Radiator/electric

fan controlled via thermostat and dashboard switch, working well though it has

yet needed to switch on in normal use.

3 Triumph

disc brakes work well enough but are very heavy in use - wonder if I can fit a

servo in somewhere?

4 14"

Minor wheels are readily available, and I think I paid £5 for a really good set

of stainless hubcaps.

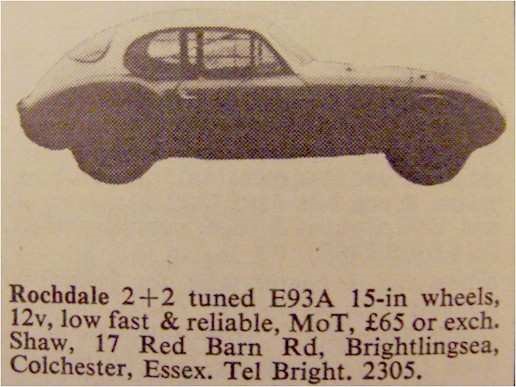

5 New

door handles. I bought these at Newark, (£4) labelled as E93A Ford items, which

would probably be the most likely original fittings.

6 Bonnet

catches/lock - like every GT I have seen, the bonnet was in extremely poor

condition. A replacement club item seemed the obvious, but there were difficulties

and we ended up grinding the gel off the lot for re-surfacing. The problem is

the slot for the air intake causing flexing/sress concentrations at this point

- be sure to put a few extra layers of glass around here if you're doing a

similar job.

7 Twin

SUs. Contrary to popular opinion, these don't gobble petrol and the GT returned

42 mpg on its Burford run - my Olympic never got anywhere near this figure.

8 Lucas

Alternator - with no electrics whatsoever present, I wasn't about to start

wrestling with a dynamo again just for the fun of it.

9 Wishbone

rear suspension. Nice.

10

Triumph chassis/ifs. Location of very hefty outriggers OVER the

existing chassis has caused problems later on - they go right where your feet

should be, and also make life difficult for the exhaust pipe.

11

VW lights + extended wheel arches. Use just about any more modern

chassis and you'll need flared arches. Very nicely fitted, they were glassed

over and smoothed above and below 12 Standard hinges are OK for bonnets and the

like, but little more than a joke as a door hinge. Never found the early Mini

type THAT robust, but you can re-bush them easily and they're a sight better

than the originals. Look right, too

13

Quarter lights - all part of the Minor package

14

Glove boxes - well actually the drivers side doesn't open since

the column had to be rejigged - and screen ventilation

15

Fresh air ventilation was nicely done, even if it used drainpipe

technology and fed in to a Mini heater, which is more than adequate for this

application.

16

More raiding the BMC/Leyland parts bin with this Mini washer

bottle/pump I found fitted in the boot of a late scrapyard Mini.

17

Vlanden Plas instruments. I actually had quite a few of these at

one time, with upmarket models far from immune from BL's usual 1100/1300 rot. I

believe the VP mods almost doubled the price of the car - why didn't they spend

a fraction of this sorting out the corrosion problems? Wiring loom had to be

made up from scratch, more interesting than you would think because of the

presence of an ammeter in the VP cluster.

18

Badges. These were turned on a school lathe before engraving and

then taking a gear knob type GT badge. Look the part, and ROCHDALE MOTOR PANELS

or RMP sounds so much better these days. Lots of rubber-necking from folks

trying to read these when on the move. Downside: they come right up to the rear

to try doing the same thing at the traffic lights.

19

Wind-up windows. Quite why the GTs didn't get these after using

the Minor frames is beyond me, but it wasn't too difficult to do. An extra

plywood frame was used to carry the Minor regulators, with a further trim card

over the top.

20

Stainless door frames. Another Minor option. Really well made, as

fitted (principally) to Travellers but also, I believe Deluxe models. Just

watch you don't end up with four-door versions - they are shorter (though I was

able to press the quarter lights into use as spares). Wish the Olympic had had

these as standard....

21

Inertia belts couldn't be hidden away as neatly as the Olympics,

but work well nonetheless. Obviously had never had any belts before we fitted

these.

22

Ex-Marlin bucket seats, on Astra-type runners. Very difficult to

get a decent position.

23

Rear seat, with folding access to the boot area.

24

Carpeted headlining, with more VP items for interior lights.

What's it like on the road? Well,

there's some good news, and some.... After all the grief getting to the bottom

of Phase II suspension vagaries, it is pleasing to note that this one handles

and rides very well indeed. Steering is light and positive (smaller engine,

set well back) with a really chuckable feel that I haven't experienced for

some time. Worries about SPAX shockers and spring rates - it must be a fair bit

lighter than a 17cwt GT6 - were unfounded. I have always found the SPAX units

OK on Minis and the like, and the rear leaf looks decidedly non-standard with a

further THREE (short) leaves over the standard cars six. Good luck or did

somebody really understand leaf springs here?

Problems with fumes - my daughter

claimed she was being gassed on a trip round the block - have been largely

sorted by careful sealing of the bulkhead and, presumably, bedding in of the

new engine parts. The exhaust wasn't so easy to sort, however, with very tight

access down the middle, and even less on the outside towards the rear of the

car. Hanging the rear box UNDER the chassis proved a poor idea, causing

grounding and even ripping off on anything that wasn't billiard-table flat.

This still hasn't been sorted with just a small expansion box on the side at

present - the rasp when pulling hard would put a 7-litre Cobra to shame...

And the driving position. I wish

I'd thought this one through earlier on. Do all GTs have their floors mounted

ABOVE the chassis? No problem when it's in a tall car like the upright Ford,

but the roof level of the GT does put this feature in the interesting

category. What did the Herald/Spitfires do? Never had a close look, but suspect

the narrow standard chassis was specially shaped to allow the floor to be

recessed below chassis level.

Also, why is the bonnet space so

restricted? I presume the forward position of the bulkhead was to allow

standard (floor mounted?) pedals from the donor car to be used in their normal

4-seat Ford location ie well forward. Mount the GT pedals/cylinders on this

bulkhead and not only do you severely restrict engine access, but there's a

real struggle when driving in order to reach the pedals at all. So you end up

elbows bent, chest against the dashboard, with your hair brushing the roof as

you attempt to lower your head to windscreen level just to see through it - at

least you won't need to worry about sunvisors... I have had several goes at

this one, just about driveable now with about 2" shaved off the seat mounts, a

much smaller steering wheel, much jiggling of the column (more to come, I fear)

and some judicious bending of the pedals.

Special word here - on the Friday

before Burford, I decided I really couldn't face the trip without the latter

pedal-bending exercise, and took the (Triumph) pedals off to attempt a rebend.

Job accomplished, I looked down at the silly little clip that holds it all

together, and remember thinking what would I do if this one were to break,

right now? Well I'm sure you don't need me to tell you that's exactly what it

did, and I'm left thinking of where do I get an old Triumph bit locally? can I

swap the clutch one across? can I use something else? Well, I shouldn't have

bothered, a call to Sportscar Supplies (Newcastle) and they sent me a new clip,

arriving the following morning, and didn't even charge me. They are always

interested to listen to obscure requests, have very reasonable prices, and the

stocking of both Triumph and MG parts (and others) is very useful when

restoring a Rochdale. Usual disclaimers.

I would definitely consider

moving the bulkhead back if I were in a body-off position again. I had this to

do on the LHS to squeeze in the twin carbs, wish I'd taken it even further back

now, and also the battery shelf had to be cut to clear the cylinder head. A

relatively easy, if drastic-looking, job is to carefully cut the offending

panel and re-glass it in place a few inches to the rear. Much better access to

the engine and more realistic placing of the pedals inside the car. For a GT

you need a) short arms b) short neck c) extra long legs and d) narrow shoulders

- the car is around 11" narrower inside than my (Mk1) MX5, itself claimed to be

a masterpiece of compact design.

Les

Browns GT6-chassied Rochdale GT (after)

Last point. Does anyone have a

solution to the door-sealing problem? The MG-type locks have caused no end of

problems. No locks were present at all when I bought the car, but some

cheap(ish) examples were bought, unused, from eBay. Unfortunately, the two

parts didn't fit together, the wedge-shaped striker being far too fat to fit in

its location, though I didn't realise this until several years down the line.

Rather than scrap the strikers - I think they were made for several different

cars, so make sure you get a matching pair, and not all MG ones are identical -

I decided to try filing them by hand. After removing a good 1/8" of metal -

yes, really - it did work, with the lock not just engaging the safety catch but

also the locating hole which it should have done in the first place.

But the seals. I don't think the

car had ever had any, which also looks to be the case in other GTs I have

seen. If, like me, you decide to rebuild the flanges, which were all over the place,

make sure you have a suitable seal available which will fit with the door FULLY

closed. I re-built mine in what appeared to be the original position, then

couldn't get the catch beyond its safety position when the rubber was fitted. A

spacer then had to be fitted under the locks, which took them into the correct

position on the striker but left the door about 1/8" or so proud on the

outside. Still working on this one, looking for some slimmer seals if I can

find them, but the worst feature is the ingress of water around the lock. The

seals do a good job of channelling the rain down to the lock level, which is

then equally effective at directing it into the car, and hence onto the floor.

The amount it ships is just amazing.

I have had a few goes at this so

far - it has even been suggested that I remove the seals again, to stop the

water being directed onto the locks in the first place, which may improve

things but can't be right, surely? So, come on, you GT users out there, what

did YOU do to fix this one?

I have some pictures up on the

website if anyone thinks they have an answer.

So there we are - definitely

still a work in progress, but equally, with much promise. It's an attractive

and unusual car and there's a very sporty feel to the handling without any of

the harshness I once had to live with. The leakage and exhaust problems must be

solvable, and the MG engine should give usefully sporty performance. Which just

leaves us with that driving position....

Les Brown

Malcolm Mckay writes:

In response to Les's comments on

his GT (terrific effort by the way.), yes it was possible to drop floorpans to

the level of the bottom face of the Ford chassis, if you had small enough seats

to drop in there. Forget adjustable seats, you built the car to fit you and

fixed them there. Adjustment runners just add height that you don't need. You

then sit with your feet higher than your bum, but it's actually not an

uncomfortable position when you get used to it. If you can't lower the floor,

you will always struggle, but aim to angle the whole seat back so that you are

more reclined - your back moves back, you get more arm room, your head comes

down lower, and your bum can move forward putting your feet closer to the

pedals. Find a seat where the bit at the back of your bum is very thin, so with

this part sitting on the floor, you get maximum headroom.

The shell was designed around the

standard Ford pedals which hinged from the chassis, with mechanical brakes and

clutch, though quite a few builders of the cars did fit hydraulic brakes and

clutch with a nicely made alloy pedal box frame and top-hinged pedals that put

the master cylinders in the top of the engine bay. Unfortunately, I've never

found the original source of this pedal box - it may have been a specialist

accessory - but it did give a comfortable driving position. Getting in and out

was a surprise for those not used to it, as the steering column passed between

clutch and brake pedals - again not a problem when you get used to it.

Re water leaks, my GT used to be

perfectly dry. It did have door seals, but they weren't up to much - they

certainly weren't fat modern seals, from memory they were just old-fashioned

felt seals - fit modern ones and you'll certainly have problems getting the

door to shut and may well end up with it sitting out a little from the shell,

which could well be the cause of it sucking water in?

Hot Car GT

The ROC website is the shop

window of the club to the entire world and an imperative requirement of any

classic car club. For such a small club as ours Aubrey has produced a superb

and easy to use site that is welcoming to any visitor. A lot of information

arrives in my email inbox from people accessing this site, admittedly I

sometimes get the offer of Manhood enlargement pills (never ones to make it

smaller) but usually I get some gems of information that help in piecing

together that all important Rochdale history that is fast disappearing. The

piece of information in question arrived in the form of a Guestbook entry on

the website that read:

I had a Rochdale GT as my first

car in the late 60s. I recently did a web search and found the ad in Hot Car

April 69 for when I sold it for £65. It was a great car but the poor cable

brakes made it an interesting drive with the performance that it had.

I write:

My name is James Farrington and

I am the Secretary of the Rochdale Owners Club and the assistant to the Early

Rochdale Registrar. I was reading your guestbook entry on the website and was

delighted to hear that you owned a GT in the past and even more delighted to

see that it may have been in the Hot Car magazine I have pictures on my website

(www.rochdaleproject.co.uk) you

saw it on. I am always trying to collate information on Early Rochdales and

would really appreciate it if you could let me have some more information about

this car? Do you remember the registration? Your car may still survive and I

may be able to let you know some more history on it. Do you have any photos?

Any information that helps piece together the history of Rochdale cars is

always appreciated.

Frank Shaw writes:

Dear James, It is good to see

that they still exist. I placed the Hot Car Magazine ad and it certainly was my

car. It was quite a surprise to see it on your web site. I was just browsing

after watching Ginetta racing on TV. That led to checking whether they were

still based in Essex on the web, then thoughts drifted to specials and a web

search for Rochdales. I was surprised to find so much about them.

Unfortunately, I do not recall the

registration number but I shall see if I can find any photos etc with it on.

It was my first car that I bought as a student with a term's grant, not really

knowing what I was buying. It looked good and was cheap from a back street car

dealer in Chelmsford. It was black on the sides with a very broad white centre

stripe. The engine used to smoke well but still ran reliably and gave

impressive performance for its day.

I also recall fitting what were

then new types of tyre, Pirelli Cinturatos to the 15 inch wheels. It handled

well but the cable brakes were not up to the performance of the car, I recall

unpredictable pulling to one side or the other. I gained a quick education in

DIY maintenance as most garages did not want to know. I particularly remember

some innovative use of joints and clamps to sort the broken exhaust. I also

remember the lack of a cooling fan. I only had it about a year because the

insurance costs were prohibitive for a young student.

Although you had the Hot Car ad,

I think it was a response to an ad in Exchange and Mart that actually sold it.

I did have another special a few years later, a Triumph based Ashley but that

did not have the character of the Rochdale. At present my lifestyle makes

modern motors the only practical choice but I am rapidly approaching the

prospect of having more time available so perhaps reliving those happy days

could become a reality again. It is good to see that people like you keep

marques like this alive. Regards, Frank Shaw.

New GT to the register

I received a phone call from

Professor David Norburn who used to be the Director of the

Imperial College of Management in

London. He had just seen the Phase 2 for sale on the Sussex County Sports cars

website (624 JAC) stating he used to own that and a Phase1. I passed on this

information to Tony Stanton to find out more and it turns out the Phase 1 he

used to own is actually a Rochdale GT that is not known to the register,

another one for the ever expanding list.

I write:

Many thanks for supplying Tony

Stanton with information regarding your Rochdale Olympic, everything helps in

collating the history of these cars. Interestingly, Tony informs me you used to

own a Rochdale GT and has sent me a picture. I am currently the Secretary of the

Rochdale Owners Club but also help the early Rochdale registrar collate

information. Your GT is one we have not got on the register so it would be

great to find some more about it, would you mind putting pen to paper or

fingers to keyboard as it is now and answering a few questions?

Professor Norburn Writes:

Really good to hear from you.

With the caveat of old age, the Rochdale GT was bought via the Exchange and

Mart around 1961/2. From recall, I think it was dark green but from the

photograph it could easily be black or dark blue. It had a Ford 1172 side-valve

engine to which I replaced the cylinder head with a higher compression Ford 8.

The car lived at 41a Highbury Hill, London N5, and, after 1964 at 9 Rees St,

London N1. I believe I may have sold this GT through Mickey Roucco who had a

small garage business at Drayton Park, London N5. This was probably in 1967

when I bought a Mini Traveller. By coincidence, Mickey Roucco sprayed my Phase

2 in 1970 from red fibre glass to electric blue. I bought the car from the

Tickner Brothers - two excellent auto engineers - but who are now dead.

I did speak to a nephew - who

vaguely remembered the car. I accessed the nephew via Google under Tickner

Brothers. After 6 Porsches and, currently, a 5.5 litre Mercedes SL I am still

nostalgic for the Olympic for sale at Sussex County Sports Cars 642 JAC.

However, I have but four garages all of which are fully occupied with

interesting cars and it would be a shame to keep the Phase 2 in my driveway.

If anyone out there remembers anything about this car, or any others I write

about then please get in touch.

OLYMPIC REGISTRAR

Just when you think you know a

lot about the history of Rochdale Motor Panels something turns up to make you

realise there is a lot more to learn.

I was aware from the factory

ledger that a John Woollatt was the owner of an early Olympic. The entry, No

1545, dated 26th January 1961 merely states White Olympic

and records that a cheque for £200 was received on 25th January 1961.

I also assumed that he was obviously known to Harry and Frank as there was no

address given in the ledger and the price charged indicated a reasonable

discount.

About 5 years ago at Capesthorne

I met Harry Whitehouse, who had owned a phase 1, 654 DXW in the early

1960s until it had been destroyed in a fire. He mentioned a John Woollatt had

an Olympic at the same time and said that this Olympic was rather crudely

constructed and looked more like a mobile test bed.

I had also discovered from the May

1960 edition of the 750 MC Bulletin that John had been involved with 1172

Formula racing and had built a monocoque aluminium bodied 1172 special called

Magalolysius. In this publication it gave Johns address as Aldersyde,

Winnington Road, Marple, Cheshire, not too far from Rochdales factory. This

was the extent of my knowledge in this respect until the following email was

received from a Terence Love in Australia.

I was delighted to discover

the Rochdale Owners Club Website. I owned a Rochdale Phase 1 in the 70s. It is

great to see some pictures and stories behind them. I was a bit surprised to

see no mention of John Woollatt in the history. I knew John well in the 60s and

travelled a lot in his Rochdale, which I gather was No2 prototype off the mould.

I remember the suspension was rather creatively held together. From talking to

others at the time I remember John was involved in/responsible for the design

of the engineering of the monocoque structure of the phase 1 and the rear

suspension for Richard. He was also involved as a test/racing driver for RPM.

It was John who identified and rectified the glassfibre failures of the rear

suspension, I seem to remember seeing some of the suspension roll and pitch

drawings and weight balance calculations at his house. Johns car had a close

ratio gearbox and a very high ratio back axle. He gave the car to a student at

Newcastle in the early 70's and it was converted to small pieces after leaving

the A1 at high speed.

The Rochdale I bought handled

badly around the lanes north of Lancaster. I changed both front and rear

suspension setup and most of the dash arrangement and after driving it a couple

of years exchanged it with John for one of his motorcycles about 1974.

As you can imagine the above came

as a complete surprise as at no time had his name come up in conversation with

either Richard Parker, Harry Smith of Frank Butterworth. Hence I replied to

Terence's email and received the following:

I can tell you a little about

Johns car. He told me it was the second out of the mould. There were some

problems with the first apparently. John was a qualified engineer and was

involved in a mixture of car design, textile machinery design and the design of

farm harvesting machinery and large scale food preparation machinery, such as

pea harvesters and high speed onion peelers.

Until about 1968 he worked for

Mather & Platt in Manchester. Then followed a year as a car design

consultant (design of a polypropylene monocoque car for Rover and some smaller projects

including boats) before moving to Newcastle Polytechnic Department of Design

(now Northumbria University). For most of the late 60s (and perhaps after) he

was involved with the Frazer Nash Club designing and arranging the manufacture

of spares. During the 60s he had a Vincent Black Shadow and sundry other racing

cars (Jaguar D type) and motor cycles. He was involved in lightweight car

design, boat design and motorcycle design until his death about 10 years ago.

Just remembered prior to Mather & Platts John was a designer on the Deltic

diesel railway engine and later, just before he died, was involved in rail

restoration on one of the Lake District Railways.

John was involved in design

stages of the Rochdale because of his work on understanding the structural

stress loadings on lightweight monocoque car structures. He'd started trying to

understand how they might work with Magalolysius, an 1172 Ford (see above),

made from NS8 panels held together with zillions of 2BA bolts. A friend

crashed it and destroyed it on its first race at Cadwell? (not quite true

as John advertised the car for sale in the April 1960 750 MC Bulletin, stating,

only 4 race meetings). I believe he had also been involved in building

various earlier RMP kit cars. He told me he had been the test racing driver

promoting Rochdale on the club circuits. He told me the racing promotion of

Rochdales was relatively short lived as it turned out the monocoque Lotus Elite

was faster.

Johns car was relatively

stripped. The doors only had an outside panel and a diagonal piece of 2 x 1

across the inside to brace them. The door windows were flat Perspex and slotted

into small clips on the top of the door. As the door closed the window tops

were trapped by the top of the door opening. There were two small ex-fighter

aircraft bucket seats with full chest harnesses. The binnacle was homemade and

sparse. There was minimal electrical equipment and fuel level was tested with a

long cane. The engine was a twin SU 'B' with special close ratio box and high

ratio back axle (19.5 mph/1000rpm in top) (amazing what one remembers!) I can't

remember if it was tuned. Bonnet was held down with two elastics. The engine

was fitted with a very large oil cooler. I remember the pipes splitting and

dumping all the oil somewhere on Rannoch Moor. John thought for a few moments

and then said that he reckoned it would be possible to drive 10 miles with no

oil if he kept the engine running about 1500 rpm lightly. It got to the garage

fine and apparently without any damage.

Wheels were large 14" or 15"

(can't remember which) and fitted with relatively skinny Michelin Xs which

lasted forever. I remember they were much larger than the ones on the

Rochdale I bought. Windscreen

motor and cables were a pain (on my Rochdale also!)

Johns car was used to test

suspensions and running gear. John was a competent suspension designer and

specialised in understanding how suspension geometry and weight shift affected

handling, steering and road holding. He spent hours teaching me to design

suspension geometry correctly! I have a distant memory someone told me John had

been responsible for locating the engine so far back into the cockpit to

improve handling. Johns car was one in which an engine mount problem was

solved (gearbox mount) and which simultaneously resolved a problem in exhaust

fatigue failure. Johns car also had heavily repaired wheel arches where the

front of the rear trailing arms had pulled through. He had added about 1" of

glassfibre. The overstressing problem occurred when the suspension arms were

under load at extreme angles. Part of the solution was to have the rubbers a

bit loose.

Throughout his life John had

protégés that he taught engineering and had a sort of unclenephew relation

with. I was his second protégé and there were probably at least half a dozen

others. All of us kept in touch with him. Most were at Northumbria Uni. Some

are now staff in the Design Dept. There are likely to be photographs of John

and his Rochdale with people in the Design Department at Northumbria

University.( I shall be following this up in due course). The people

there still remember him (I was there last year interviewing the head of the

Design School as part of a research project).

That's about as much as I

remember about Johns Rochdale, except he gave it to a student who crashed it

on the A1. John dismantled it to keep the running gear and then sawed it up

with a hand saw into small enough pieces to put in a builders skip.

I gave him my red and silver

Rochdale I 1972/3 in exchange for a Triumph/BSA motor cycle (I was at Lancaster

Uni. at the time). He kept it for a while then I think he gave it to another

student at Newcastle. I remember him being a bit critical of the quality of it!

Hope some of this rambling may

be of help. Terrence Love.

To try and verify the above I

contacted John Dunwell, who worked with Richard on the construction of

the moulds for the Olympic and is one of the few original employees of RMP who

is still around. This was his reply.

It's nice to hear the Olympic

owners are so well represented as I was involved from day one when we set up

the formers and chicken wire to start the whole process. The person you mention

does not ring a bell, but is fifty three years since it all started. Many people

came into the workshop and passed opinion as to shape. By the way did you know

we ruined a former dance school floor with the plaster work involved?

I do know that when the moulds

were complete that an odd shell was sold off as a lightweight until the correct

thickness was decided upon, so Mr Woollatt is quite likely to have had the

benefit of a very early one.

As you say, Richard was very

modest about it all and it was a privilege to work with him for six years until

1963 when we both left. Sorry I cannot be of further help, but anytime just

ask, something may come out of this head.

Regards, John Dunwell.

So, the mystery as to Mr

Woollatts involvement with the Olympic continues. I will be contacting

Northumbria University to see if any photos still exist. I suspect that any

testing carried out by John Woollatt was as an unpaid helper (I understand

Colin Chapman used the same technique at Lotus!). Perhaps also there was a

degree of over emphasis on his involvement to his protégés.

Derek Bentley

FITTING

A HEATER TO THE OLYMPIC

Rochdales offered a heater as an

optional extra to the phase 1 Olympic. In fact the original owner of my car

paid an extra £15, although there is no evidence that it was ever fitted.

I was always curious as to what

was actually supplied and it was only recently that, on viewing the photograph