MAGAZINE No 121 SPRING 2010

Edlines

Do take the trouble to read the FBHVC

articles in these magazines for example this issue contains a lot of very

informative and useful advice, from fuel to registration to scrappage to

antifreeze and more.

For what is Rochdale famous? I knew

of the Co-op and Gracie Fields, but I discovered that one John Ravenscroft, aka

John Peel, also had associations with this town. He worked at the Townhead

Mill as a teenager and later played many of the records recorded under John

Brierley at Cargo Studios (later Suite 16) on Kenion Street (off Drake Street),

which was very active in the 1980s and helped to launch the careers of many

young bands.

Rochdale

Social Event

Hi All,

A New Year and a new attempt at getting

a Rochdale Social Event off the ground!

The RAF Motorsport Association opens

up its old Bloodhound missile section at RAF Barkston Heath to motoring clubs

to have track days and speed trials. This is a great opportunity to test your

cars and driving skills, you are the only car on the track at any one time so

risk of damage to your car is very minimal with good run offs should you need

them; more info can be found at:

www.raf.mod.uk/rafmotorsports/4wheels/rafmsaspeedchallenge.cfm

For 2010 I have reserved 4/5

places on the RAFMSA track day on Saturday 3 July. The format is a sprint style

track day, with open pit lane. There will be around 30 to 40 cars at each track

day but I can assure you your track time will be more than enough! The cost will

be a very low £50 for the whole day and includes as many sprints as you can

manage; all you need is a helmet and a car! This is a professional event and

fully marshalled and accurately timed. Saturday evening will be camping at the

nearby bubble car museum rally field at £5 each, they do have a B + B option at

the museum, £28 for single occupancy and £50 for double occupancy should any

off you want to cuddle up!

http://www.bubblecarmuseum.co.uk

We will also get a chance to look

round the museum and if time allows get some photo opportunities at the nearby

RAF Cranwell with the cars. A few social drinks in the evening regaling our

stories from the day's events. On the Sunday I should be able to arrange a

professional presentation and hands on practical of GRP repair techniques about

15 miles away from the bubble car museum. If you copy

http://www.youtube.com/watch?v=_NELlwZW_Fs

into your internet address bar, you will see an in car video

of the track. There are also loads of other videos if you just type in

"Barkston Heath track day". A very professional and great day out.

So to recap:

Saturday day, Sprint challenge,

Saturday eve, Bubble car museum

and a few beers to recap on the day's events.

Sunday morn, possibly back at the

track if I can organise it.

Sunday fternoon, GRP presentation

A bargain price and an exhilarating

day out. All I ask is that I can be a passenger in someones car!

Initially all I require is a

realistic indication of how many cars/owners want to participate so I can plan

likely attendance. I might also open this up to other 50's / 60's specials if

the numbers aren't enough.

So, anyone who is interested and

will have their cars on the road for this years Rochdale Anniversary, let me

know by the 18 March 10 and I'll reserve you a place.

James Farrington

TONY STANTONS EVENTS PAGE

STONELEIGH KIT CAR SHOW 2ND & 3RD MAY

2010

Just to let you know I have reserved

stand Number 39D for all HISTORIC SPECIALS AND CLASSIC KIT CARS built before

1973 at the N.A.C. Stoneleigh Park, Warwickshire, the show for every kit car

enthusiast with old or new kit cars. Sunday 2nd and Monday 3rd of May 2010,

from 9.30am till 5.30pm. (May Day Bank Holiday weekend).

All kit car drivers are admitted

free of charge, passengers are1/2 price.

You can camp on the site, tents and

caravans, please contact the organisers office 01775

722900 for details and forms

www.grosvenorexhibitions.co.uk

This is a very good cheap day out,

spares are cheap, where else can you buy brand new crossflow radiators for £15

to £20 and new electric cooling fans for £5?

There are 5 large Exhibition Halls

and 600+ Trade Stands all the things you need for your rebuild or update. You

can look at new kit cars in rolling chassis form indoors in the dry and warm

which will give you ideas on suspension, brakes and drivetrain modification for

your car.

This is the best show of the year

for kit car engineering.

Come to the main vehicular entrance

which is located on the B4113, the Coventry to Leamington Spa road (follow

signs for clubs and exhibitors (do not go into the Public car parks) NB only 2

miles from where we used to have the A.G.M.

WITH CAPESTHORNE NO MORE, LET'S HAVE

A GOOD TURNOUT OF ROCHDALE

CARS AT THIS EVENT INSTEAD,

PLEASE tell everybody you know with a

suitable car and place details on websites if you can, let's have a good

turnout of Rochdale cars.

Contact Tony Stanton (Rochdale

Olympic 902DUF) tony-stanton@fsmail.net

7th PRESCOTT HILL CLIMB CLASSIC CAR EVENT 9th

May 2010

Any R.O.C. member attending this

event with their Rochdale please contact Derek Bentley or Tony Stanton.

SILVERSTONE CLASSIC on July 23rd, 24th & 25th 2010.

In conjunction with the F.S.C.C. we

have secured a designated display area within the Historic Grand Prix circuit

at this 3-day event, and we are seeking further club marque cars to join us on

display during the weekend.

Featuring 22 races, 800+ competitors,

and 600 of the most valuable race cars and motorcycles in the world. On top of

the mouth-watering line-up of races lasting between 20 minutes and 1 hour each,

starring the very best single-seater, GT and Touring Cars from the past 80

years, the entire infield will be packed with more than 4000 classic cars

showcasing in excess of 50 famous marques.

There will also be a period funfair,

air displays, trade stalls, live music, barbecues and more than 30 hot air

balloons are set to fire up for their traditional morning and evening fly-outs.

DUFFY and I have been to this fabulous

event for the last 5 years and I think it is better than Goodwood. You can

walk around the paddock and in the pit garages at any time, talk to the

drivers, watch the mechanics working on the cars close-up and just to wet your

appetite the last race on Saturday is a 90-minute race for Sports Racing Cars

from the late 60's (i.e. GT40s Lola T70s and Chevrons) racing into the dusk

with their headlights on, so be there with your marque car you are going to

love it (ask Derek and Alan).

To enter your club car in the

FSCC/ROC display area please contact Tony Stanton on 01527 402367 or tony-stanton@fsmail.net

and I will issue the club reference number to quote when booking tickets and

Marque Car passes.

American adverts

Thanks for this to James Farrington

who found Olympics mentioned in old American car magazines (the wonders of

the Internet and Google).

a) Sports Car

Graphic July 1964

Sports Car Graphic has on

several occasions carried mention of the so called kit car the Rochdale

Olympic. Some of your eastern readers may be interested to know that an Olympic

is now operating on the East Coast. Acquiring a small car by mail is in itself

a sporty proposition, but it has been very well worth the bother. The car is

delightfully agile and responsive, being powered by the English Ford 116E

engine that was featured in your magazine. The full monocoque fibreglass body

is rigid and tight and has exceptionally pleasing lines fore and aft. All in

all, the car offers more real personalized sports car for the money than can be

approached in any other way! The total cost to my front door including all

transportation, duties, etc was about $2450. I would be happy to correspond

with any of your readers who are interested in the Olympic. Robin Rackham's letter

- similar to this one - appeared in your Jan 64 issue but the address he gave

was insufficient, and my letter to him was returned undelivered.

John D Bitner, 1407 Ellenglen

Road, Towson 4, Baltimore, Maryland, USA.

b) Sports Car

Graphic July 1965

ROCHDALE OLYMPIC PHASE II GT 2x2

Kit, Fibreglass, Cortina 1500cc tuned Ford, 100 mph + 35 mpg, Major components

custom factory installed. 75% complete, Needs:

Instrumentation, seats, exhaust,

brakes (supplied) lacquer. Best offer.

Martin, 2151, 8th Ave, New York,

NY 10026, USA

c) Car and Driver

July 1971

1965 ROCHDALE OLYMPIC PHASE 1

1.5litre GT. new 1963, 1600cc MGA drive line, new BFG 990s, mechanically

excellent, needs paint job, best offer over 1,000. Don Usher, Allen park, Michigan 48101, 313 388 3817.

FBHVC NEWS

Fuel Changes

Update

A further Stakeholders Meeting took

place in October at the Department for Transport (DfT) in London. Following the

meeting an information leaflet was issued to help those who may be affected to

prepare for the proposed fuel changes. [Only petrol information is given

here Ed]

Ethanol in

Petrol

Concerns expressed by Federation

members have been raised, in respect of fuel system corrosion and also high

fuel volatility, which has been causing operational difficulties. The oil

industry position is based on a safety concern over reduction of volatility.

The validity of the safety concern was questioned and is now being checked by

DfT, but it seems unlikely that there will be a reduction in fuel volatility

other than a small correction to reflect the blending of ethanol into the fuel.

It is confirmed that Shell V-Power

petrol is currently guaranteed not to contain ethanol. It is not an exchange

product, being unique to Shell, so is under their close control, unlike most

other fuels sold at filling stations. Thus for the time being, members wishing

to avoid petrol containing ethanol can buy this product, which also has the

advantage of being widely available.

The issue of corrosion concerns with

petrol containing ethanol is being pursued further, but at present there is

nothing more to report.

Lead

replacement additives

Testing for suitable lead replacement

additives took place prior to the withdrawal of leaded fuel in 2000. Since that

date only very small quantities of leaded petrol have been permitted to be sold

for historic vehicles by licensed garages who are members of the FBHVC.

The Federation originally tested 12

products to assess their performance in protecting against valve seat recession

using identical test procedures on a Rover A-series engine. The results were

conclusive and showed clear differences in performance between the various

products tested. Those products that did pass the test were allowed to carry

the FBHVC logo and the words: endorsed by the FBHVC or: This

product has been subjected to a valve seat recession test by an independent

test house on behalf of the FBHVC. The results of the test indicate that the

level of valve seat protection is likely to be adequate for all normal driving,

but not including racing or other exceptionally arduous uses.

Since then a number of these products

have been withdrawn from sale but the following are still available:

Millers VSP-Plus

Red Line Lead Substitute

Castrol Valvemaster and Castrol

Valvemaster Plus

Each of these products has a

different active ingredient and it is recommended that these products are not

mixed in the petrol tank, in other words, choose one product and stay with it.

Tetraboost, which contains tetraethyl lead is, of course, also available from a

number of stockists.

DVLA

Nigel Harrison

The Federation recently had one of

the regular meetings with DVLA which was as usual very informative. Some of the

points raised are detailed below.

Registration of

historic vehicles

The DVLA leaflet INF

26, Guidelines for the Registration of Rebuilt or Radically Altered

Vehicles and Kitcars, gives

definitions for Radically Altered Vehicles and Reconstructed Classics and

allocates a point score to the various major components of the vehicle. The

chassis or monocoque bodyshell scores five points; suspension, both axles,

transmission, and steering assembly all score two points each; the engine

scores one point. If an already registered vehicle is radically altered then,

provided it scores more than eight points, it may retain its original

registration number. For a vehicle with a separate chassis, the body is not

scored by the points system, so a new body should not affect the retention of

the registration number.

However, for a vehicle where either

there is no documentary evidence to claim the original number, or if the

original number is unknown, then an age related number should be allocated

assuming the criterion of Reconstructed Classics is met. The definition is: Vehicles

comprising genuine period components of the same specifications, all over 25

years old, will be assigned an age-related registration mark. The appropriate

vehicle enthusiasts club must confirm the authenticity of the components.

I had assumed until now, that the period components were the major mechanical

components in the radically altered points system.

However, it appears that this may not

strictly be the case. The consequence of this is that the installation of a new

body prior to registration could mean that the vehicle is allocated a Q

plate. The principle is for genuine period components of the same

specifications, all over 25 years old should be used. It therefore follows

that the vehicle should be registered with its existing over 25 years old

body still in place provided, of course, that it can meet the MoT requirements.

Only when the vehicle is registered, should a body replacement be

contemplated.

This particular case came to light

because the owner passed to DVLA a receipt for what could be interpreted as

being a new body. There has been another case where the DVLA local office has

required that form V627/1, entitled Built Up Vehicle Inspection Report

is completed. This form requests receipts for replacement parts. It is

perfectly understandable that if DVLA are given information they will take it

into account when assessing the vehicle. The moral of this story is that if it

is an age-related application, careful consideration needs to be given to how a

vehicle and its documents, including the covering dating letter/certificate, are

presented to a DVLA local office.

Declaring SORN on

a newly acquired vehicle

SORN (Statutory Off Road

Notification) is only applicable to a vehicle whose licence disc expired on, or

after, 31 January 1998. If you have just acquired a vehicle that is subject to

SORN, a recent case has indicated that the on-line SORN system should not be

used to declare the initial SORN under your new ownership. This is because of

the way in which the SORN legislation, and on-line SORN system works.

If a vehicle is being taxed, then it

is perfectly normal for the new owner to take over the unexpired period of tax.

However, the SORN period starts at the beginning of a month, and then stops

when there is a change in ownership. The online SORN system can only start a

period of SORN at the start of the month, and then stops that SORN when the

ownership changes. SORN cannot be made online within the month of registering

as keeper.

If you have acquired a vehicle, and

you are going to declare SORN, as well as filling in the V5C to register the

change of ownership, (or V62 if V5/V5C was missing) it is essential that you

fill in a V890, (SORN form) as well. The V890 SORN form is available for

download on line from www.direct.gov.uk, or should be available

from a main Post Office. Staple these forms together, and send to DVLA Swansea,

SA99 1AR. I would suggest that it is always wise to make copies of these forms

before sending them off.

You should receive written

confirmation of the SORN declaration within four weeks. If no acknowledgement

letter is received, then the DVLA instructions are that you must contact

Customer Enquiries Group on 0870 240 0010 immediately.

In summary, new keepers should make a

SORN declaration via the paper based SORN V890 application form.

Scrappage

In response to a question from one of

our member organisations regarding how an historic vehicle that has passed

through the Scrappage Scheme could be saved, the Department for Business,

Innovation and Skills (BIS) sent the Federation the following statement:

A Certificate of Destruction must be issued for all

Scrappage Scheme vehicles. Whatever their age or condition, these vehicles are

effectively being declared End of Life Vehicle (ELVs) by their last owners at

the dealerships which accept them. To comply with the 2003 ELV Regulations, the

vehicle must be initially treated at an Authorised Treatment Facility (ATF), to

the standards required (fluids drained, battery and tyres removed, airbags

deployed or removed), and it would then no longer be classed as hazardous

waste. The scrapping process could stop at that stage and the vehicle could be

preserved and sold on, should the ATF wish to do so. Although a vehicle should

not be put back on the road, even if this is possible, it could be saved for

display or donation to a museum.

Further information is available

from the Vehicle Scrappage Team, Tel: 020 7215 5000

Email: scrappage@berr.gsi.gov.uk

ANTIFREEZE

Technology moves forward and new

products are constantly being launched with claims to improved formulations and

performance. With the recent bitterly cold weather in January antifreeze has

been in the headlines, with some alarming stories which at first seem to be

about the well-known tendency of antifreeze to find the tiniest hole and cause

leakages but in these cases it has led to catastrophic engine problems.

Traditional blue ethylene glycol is a

toxic but highly effective antifreeze and contains silicates as an inhibitor to

help prevent corrosion in an engine with mixed metals in its make-up.

Bluecol and Blue Star are well known

brand names and both of these are declared suitable for classic cars on their

company websites. Be aware that there are also low- or no-silicate ethylene

glycol formulations (usually red) available which may not be suitable for all

engines.

Propylene glycol is another

well-known and less toxic antifreeze formula and usually contains silicates but

Comma, the main manufacturer, have now discontinued it in favour of an ethylene

glycol product containing bittering agents to make it less palatable and

minimise the risk of accidental poisoning.

Both of the above products use

inorganic additive technology (IAT). Recently problems have been reported

concerning the use of antifreeze mixtures using organic acid technology (OAT).

OAT was introduced in the mid-1990s and the products are biodegradable,

recyclable and do not contain either silicates or phosphates and are designed

to be longer lasting. However, these products do seem to cause problems in

older engines; over and above the ability of antifreeze to find the smallest

crevice and leak. OAT antifreezes have been accused of destroying seals and

gaskets and causing a great deal of damage in old engines. For this reason,

the manufacturers do not recommend their use in historic vehicles. These

products are usually coloured red, pink or orange.

The final category is HOAT. These

products use hybrid organic acid technology in an ethylene glycol base with

some silicates in the formulation alongside the organic corrosion inhibitors.

The product is usually coloured green and are not recommended for use in

historic vehicles.

The Federation are still researching this problem but

our advice at the moment is:

only use blue coloured IAT antifreeze in historic vehicles;

only use OAT products (advanced or long life antifreeze) if

the vehicle used it when new and if specifically directed by the vehicles

manufacturer;

never mix different types of antifreeze without thoroughly

flushing out the system;

always replace the coolant within the time scale specified by the

antifreeze manufacturer as the corrosion inhibitors break down over time.

DRIVE IT DAY

We have been very busy already

answering the question when is Drive It Day 2010. The event is always held on

the nearest Sunday to 23 April, so this year it will be 25 April 2010. This day

was chosen five years ago to commemorate the 64 cars that set off from London

on 23 April 1900 on the first day of the Thousand Mile Trial an incredible

undertaking and one which we believe deserves an annual celebration.

We have had so many requests to

advertise DID events that we have made a dedicated page on our website events

section for just this day. The same rules apply as for other events member

organisations may add details using their ID number and password issued last

year.

The Royal Oak at Bishopstone

(about 5 miles east of Swindon, SN6 8PP, 01793 790481), a superb venue with a

self-confessed classic car nut for a landlord, and with excellent food and

beer, has once again indicated that they will be delighted to welcome all

comers on the day.

EARLY ROCHDALES

James Farrington

Now that I've finally moved

house, I've unpacked the boxes, settled my Olympic into its new garage, managed

to find a home for all my tools (that doesn't involve a kitchen cupboard) and

organised the garage by stacking all my spares in a fashion the Tate gallery

would be proud of, I can now do some work on my Olympic project (Olympic in

both senses of the word)! My challenge is to see if I can get the bodywork

finished before the birth of my next child, although that is 6 weeks away and

since in Rochdale work years that multiplies by 20, there goes that pig flying

by my window again!

Anyway, enough ramblings on, not

only has it been a busy few months for me but also for the early Rochdale

scene; every few weeks a new discovery has been waiting and the surprises just

didn't stop appearing! I do try and vary the Marks of Rochdales talked about

in this section of the magazine but I'm afraid the GT is going to feature a

fair bit in this issue as 8 have reared up in the past few months! So, where to

start???

UNKNOWN MARK VI

I'll start with the discovery of a

Mark VI Rochdale that I can't really take the credit for. With not having much

time to rummage around the World Wide Web over the past few months it was with

great pleasure that I received a call from a Rochdale member pointing me in the

right direction of a past Rochdale Owner. It is a great embarrassment though

that I can't remember who it was, please remind me and I'll give credit where

credit is due in the next issue of the magazine. It was a few months back and

I've had one too many Christmas/New Year parties since then, only excuse I can

come up with, my apologies!

Following the initial lead of just a

phone number, I managed to speak to a surprised gentleman called Phil Matthews.

I say surprised because his opening line was Blimey that was more than 50

years ago! When trying to trace the history of these cars I ask details like

names of people sold to and bought from, but memories tend to fade and this

unimportant information to some normally disappears into history. Luckily

Phils memory has stood up to the test of time and he managed to track down

some pictures!

Phil writes:

Success at last, I found the

pictures of my Mark VI lurking in a dark corner of my computer. I am afraid the

quality is very poor, and I have searched for the originals (which may have

been a little better) in vain, so I hope these will do? They were taken with an

old Brownie Box camera and have deteriorated over time.

With regard to the car, I think

you already know that it was built on a 1938 Standard Flying Nine, which my

Father had handed down to me in about 1958. I had to sell my Gold Star bike

(due to Police harassment) so I spent some considerable time stripping the

engine down and reconditioning the Standard. Unfortunately, in avoiding a

head-on collision with another car, I rolled the Standard over, and wrote it

off!

Having spent the time and money on

the car, I didn't want to scrap it, so I decided to put a Rochdale shell on the

chassis. I used heavy duty plywood for the floor and aluminium sheet to make

the wheelarches. I made a wooden dash and used the original instruments from

the Standard. I had it registered and put on the road, and had quite a bit of

fun with it before I met my wife to be, and sold it before I got round to

fitting a windscreen. I hope this helps your Magazine, and is of interest to

your members?

This is only a small piece of history

from one of these rare cars but nevertheless it could be another piece of the

jigsaw that will come in handy further down the line. This now makes the total of

Mark VI Rochdales known to the registrar as 29, still a long way off though

from the 150 estimated that were produced! While I'm on about the history of

these cars I'd just like to reiterate, if you know of anyone owning a car or

have any knowledge of an early Rochdale please get in touch as everything

helps, no matter how small (size doesn't matter in this case)!

If anyone is interested, there is

still a Mark VI for sale in Germany for 9900 Euros. Type the following address

into your web browser to view it:

http://www.wellssow.de/autodb/readpub.php?f=2&i=82&t=82&seite

UNKNOWN GT

I found the picture below whilst

surfing the net, looking for any information on Rochdale cars that has not

already been collated. I don't have much information surrounding this

particular one but I thought I'd show the Rochdale Community to see if it rings

any bells?

The article states:

The picture was taken after a

treasure hunt in 1960. The car is a Rochdale GT and was built by Arthur James

from Beverley. The car is built around a chassis from a 1937 Ford Prefect. The

following picture shows some members of the club in the early days. The trophy

shown on the bonnet of the car is now used as the Grovehill Trophy for our 12

cars

Picture courtesy of Hull Daily

Mail Publications

There are a few clues in the

article but as of yet I've not turned up trumps with any more information. Have

any of you ever been involved in the Beverley and District Motor Club? The GT

pictured is not known to the Early Rochdale Registrar but was obviously

treasured by someone in this popular motor club at some time. If anyone can

shed any light on this photo or fancies trying their hand at some internet

sleuthing, then please get in touch. Maybe we should have a competition page in

this months magazine called spot the owner, my moneys on the guy in front of

the headlight, any takers?

JOHN SAXON GT

I was really happy when this next GT

picture appeared on my computer screen, mainly because I had decided to search

for Ford Specials on an image search engine and out of nearly 21 million

pictures available this one popped up almost straight away!

The article accompanying the

picture read:

What a blast! Woodford was a

great place, working with a super bunch of guys! I had (for its time) a

sexy-looking fibreglass Ford special car at the time. Actually it was a total

heap, running on a hotted-up Ford sidevalve engine. But it looked vaguely like

an Aston Martin DB2/4 (or so I thought) and as I fancied myself as a bit of a

James Bond type, the car was ideal for me. When we got some snow it was great

to drive around the Airfield on full reverse lock using the throttle to steer

got up to 70mph sideways on more than one occasion. The Data Analysis section

used a hut out on the airfield with a car park covered in cinders out front. My

big thing was to come screaming into the car park and do a nice

handbrake-induced slide though 180 deg with the object of being neatly parked

at the end of it. Unfortunately, I overcooked it one day and sideswiped Doug

Harriss Rover. As he was also my boss, he was definitely entitled to take a

dim view of this. I remember that Doug was remarkably good about it, but I know

what I'd say to my son if he indulged in such behaviour!

This time I managed to track down the

owner, a Mr John Saxon who has since emigrated to

Australia. Answering in a very

familiar tone to my regularly asked questions,

John writes:

Hi James, WOW that's nearly 50

years ago! I have to be honest when I say that as a Testosterone-driven young

guy - I was far more interested in looking like a James Bond type than

maintaining cars - and the Rochdale (had forgotten the name) was the closest

thing I could find in my price range that looked vaguely like a DB2/4!

I bought it secondhand - sorry

no record of the transaction, and I don't know if the guy I bought it from was

the original constructor. It was probably based on a Ford chassis - certainly

it had a hotted-up Ford E93A sidevalve engine! And from memory it had a heavy

Van clutch with a 3-speed close ratio box and a very high differential ratio.

It was extremely tricky to get going from stationary on a hill owing to

fearsome clutch judder. Lots of work needed to be done on it but I was too busy

having a good time. I even had the bonnet blow up and almost block my view one

day while driving across Vauxhall Bridge in London! The only car I ever had

where I ran out of petrol, oil and water almost simultaneously!

When I came down to Australia on

my first couple of trips before migrating, I almost had it shipped out. I had

visions of reproducing the shape in fibreglass - no worries about intellectual

property in those days! But in the end I had to leave it with a 2nd hand dealer

on consignment (in Bournemouth I think) - and it sold for almost nothing.

About all I can remember

unfortunately. If I come across any documentation or more photos I'll let you

know, but I really don't expect to find anything. If you do manage to track any

of its history - I'd be interested to know about it? I have attached another

picture (B & W unfortunately, the car was solid Red colour) - but this time

you can clearly see that the registration number was 965 CJH. I think it's the

only picture I have.

Malcolm writes:

Isn't it a shame that the

high-spec cars have always disappeared - I have a theory that the highspec cars

were stripped of their best bits and scrapped when they failed an MoT, because

the tuning bits were worth more than the car, whereas the basic-spec cars just

got pushed to the back of the barn/garden intact and survived. With close ratio

gears and high ratio axle (probably 4.4:1) it would have been a nightmare for

hill starts with 17in wheels - probably the builder had a set of Ballamy 15in wheels

on it but took them off when he sold the car. Mind you, with a tuned engine it

was probably good for 90mph on the big wheels!

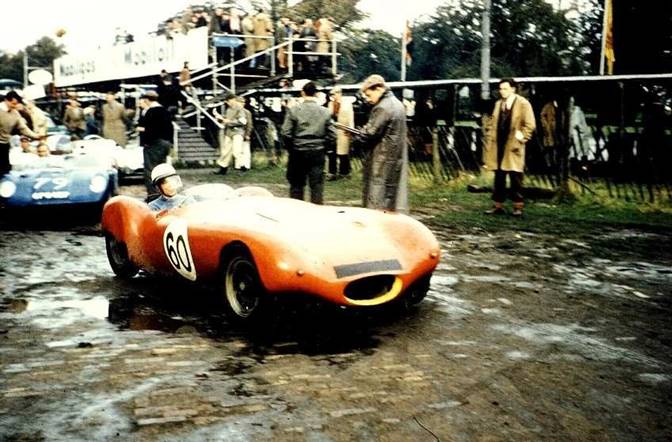

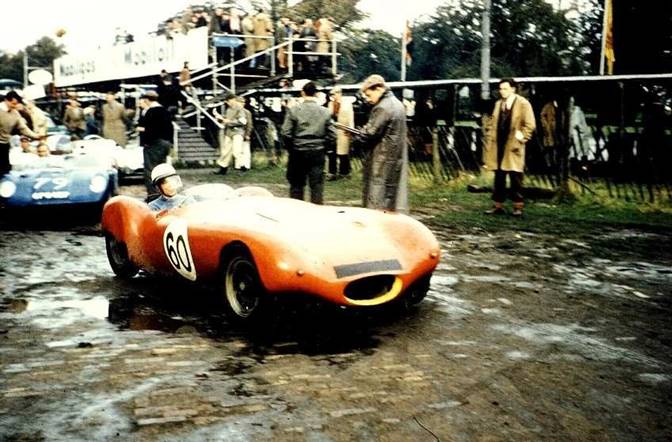

THE FUTURES BRIGHT, THE FUTURES AN ORANGE GT!

Normally I get up with my usual

dreary morning eyes, I pick up the mail from the front doormat and open the

usual bills and junk mail, but occasionally I'm woken from my dreary morning

blues by something quite exciting and this is no exception!

As I opened the envelope I

instantly recognised the Owners Club application forms but it was the pictures

that fell out that really caught my eye, there on the table were 3 pictures,

not the usual projects I see but a highly modified roadworthy example! With

only around 4/5 roadworthy examples known (1 later in this article) I was shocked

I'd not heard about this before!

Patrick Martin writes:

The car is in extremely good

condition inside and out, having been totally rebuilt between 2003 and 2006 and

having only done 10-15 miles to and from the MoT station in September 06 until

the present day. Body sprayed in 2-pack paint, and overall look is stunning.

The interior was all new, seats, carpets, door vinyl and vinyl headlining and

still all looks very tidy. The wheels and tyres are as new.

The chassis, suspension and

brakes were all refurbed and are all in good working order, reconditioned

engine runs superbly! Homemade dash using Triumph GT6 dials and switches

finished in padded black vinyl being both neat and functional, with working

heater and fan.

Wanting to know more information

about this I gave the owner a call:

The car was bought from Margate,

Kent from a washing machine repairer whose surname was Davies. The seller of

this car bought a house in the late '90s and found the car sitting in some

outbuildings! This owner purchased the car in 2003, it was on a rolling chassis

with sidevalve engine and it was never registered! He did a restoration until

about 2006 putting the shell onto a GT6 chassis (hence the larger rear arches).

It was MoT'd and has only done 15 miles between 2006 and 2009, staying under a

cover in the yard for the past few years!

DAVE SPILLER GT RESURFACES

As I hinted in the previous

article, the next GT has resurfaced and from the look of it in better condition

than ever. I'd seen snippets of this car in a few magazines including the

January issue of Complete Kit Car Magazine from the Classic and Kit Car show at

Exeter last year but confirmation that the car still resided with club member

Dave Spiller was only received via his son, Paul Spiller, when he joined the

ROC last month! [Picture supplied by grandson James!]

This GT is a particularly special

one within the club as it has been in the same family ownership for over 50

years; you could say it is one of our flagships! The car was built by Dave

Spiller and Paul Spillers Grandad Harry Moore and was originally built for a

Mk VI Rochdale body in 1954 using a 1939 Ford 8hp van as a donor vehicle. In

1959 Dave Spiller sold the Mk VI and bought a partially-built Rochdale GT. The

chassis was redesigned so the body would fit and re registered in 1960. The car

then came off the road in 1965 and was put in storage. Since 1995 Dave Spiller

has been gradually rebuilding it into the fine example you see here today!

If there is ever an excuse to

dust off your magazines and look at some old ROC articles then don't hesitate

to find the story behind this beauty in the Summer 2000 ROC Magazine, No 82. If

you don't have a copy then they are available on disk or back issue from myself

for a modest fee! Sales pitch over, you should also be able to see this GT at

the Stoneleigh Kit Car Show on the Sunday and if I can persuade the Spiller

family to trailer it up to the NEC then we might be graced with its presence at

the National Classic Motor Show in November!

THE DEMISE OF A GT

This next finding came from a

previous owner who just wanted to let the ROC know about a GT he used to own, I

wish more ex owners were like this.

Ken writes: Hi. I have sent you

a picture of the car I owned in 1959/62. I sold the car to raise a deposit on

a house when I got married. I wish I had it now. The person who bought it

turned it over and it caught fire, totally destroyed but he was okay the silly

idiot. I now own, some 47 years later, a Triumph 13/60 convertible but I would

willingly trade it for a trip down memory lane by owning a Rochdale. Happy

days!

Malcolm writes:

Great to hear from you - thanks

for sending the photo of your GT! What a shame to hear the car's fate - it's

the first one I've heard of turning over, he must've been doing something

particularly stupid...

It's a coincidence that you now

own a 13/60 convertible - my first car (aged 18, in 1981) was a 13/60

convertible but my second was a Rochdale GT! I've had a couple of other GTs and

other early Rochdales since, but I'm sad to say I don't own one at the

moment.... They do turn up from time to time, so keep your eyes peeled.

I'd like to include details of

your car on our Register, even though we know it's no longer around. Do you

still have any more details of it, such as registration number, chassis number,

spec (chassis, engine, gearbox, suspension etc)? Did you build it yourself?

Ken Writes: Hi Malcolm, the car

was immaculate; I did not build it though! It was based on a 1947 Ford 10,

Sadly I do not have any more details, and it was a long time ago and many more

cars have come and gone since so I can't help.

VICTORIA CLIMAX

Below are 2 photos which were

kindly sent to Malcolm by Andy Hill, I don't think they need much presenting, I

know I've enjoyed just getting the feel from them, cracking photos!

Andy writes:

Hi Malcolm, I have some cracking

photos of the Victoria-Climax, which as you know also used a Rochdale body like

the Bristol Barb (more in the next mag). Did you know though, that Ced

requested a "lightweight" version which was like a jelly when it was

off the car as it was so thin! He also hacked the back end off to save weight

and inadvertently created a Kamm tail!

Best regards, Andy Hill

Malcolm writes:

Wonderful photos, thanks Andy!

Especially good to see the colour shot from back then; would you mind if we

used them in the club magazine?

I'm not surprised at the

lightweight shell - RMP learnt early on that they could make a nice profit by

selling a 'lightweight' bodyshell for more money than standard - and it cost

them less because it had less materials in it! To be fair, they might have used

woven mat for the Victoria Climax shell, which was more expensive than their

favourite chopped strand mat but of course much stronger... I don't actually

know of RMP using woven mat ever, though - whereas Bonglas, from whom they

bought the ST bodyshell design and moulds, always used woven mat.

Andy writes:

Yes no problem, you can gladly

use them for the Rochdale owners mag, and a credit/plug would be great for my

Classic Car Sales website! The web address is

www.victoriasportscars.co.uk

FASCINATING FORD

The picture below was also found

whilst I was surfing the net, honestly I don't spend my life on there! The

Rochdale GT in the picture was owned by Ray Kell and was listed in a Ford

Owners Club website by his son.

Ray writes:

Hi James, you sent an email to

my son regarding the Ford Rochdale I owned. I can give the following

information.

I bought the car in 1961,

selling my AJS to buy it, and sold it in 1969. The reg number was SVN 168. It

had a 1172 cc Ford Ten engine with a skimmed Ford Eight Head, twin Solex carbs

and a short straight through exhaust that exited from the nearside at the back

of the door. I fitted an external mounted oil filter and a heavy duty dynamo

and regulator. When I bought the car it was white but I had it repainted in

Ford Monaco Red and added the Ford stripes. It had electric wipers and fuel

pump from a Morris 1000. The dash was rebuilt in Formica with a glove box on

the left, switch panel in the centre and instruments in front of the Driver,

Speedo, Rev counter, oil pressure, ammeter, water temperature and fuel gauge.

I also changed the steering

column and fitted an extended one from a 105E Anglia. I also fitted a tow bar

fabricated from 2" angle. It had a split Bellamy front axle, remote gear

linkage and 15" wheels. On the electrics it had quartz headlight bulbs in

the VW lights, 3 quartz spot lights and 2 front fog lights, signpost light,

Lucas heated bar on the screen in front of the driver, rear electric wiper and

windscreen washers, manual pump operated.

When I sold it I had just

purchased a hydraulic kit for the brakes but did not get around to fit it. I

also had to extend the battery shelf as I fitted a battery from a Bedford Truck

as the normal 6v would not turn the engine over in the winter.

The car suffered two significant

problems, repeated failure of the rear axle, which was repaired by removing the

total unit including transverse spring and prop tube and fitting one from the

scrapyard. The other was blowing of the head gasket. This was solved by the

local engine machine shop drilling and tapping the block and fitting an

oversize stud in the centre of the block then torquing the head down to a

higher value than normal. I cannot remember the value but it did work. I had no

power output but did run the speedo up against the zero stop when travelling

to/from Teesside to Cardiff where I worked, and no motorways then, other than

the Doncaster bypass.

Corrosion was not a problem as

the original builder had the chassis red lead coated and the floor plates

fitted were galvanised steel. It only broke down once that I remember, and that

was a rear axle failure near Newark on the way to London, I continued down,

then back to Teesside, then fitted another scrapyard unit. The photo was taken

in 1968. Hope this helps.

I write: Thank you very much for

all the information. I have record of nearly 200 known GTs on the Rochdale

Register but yours is a new one to us! We think there were around 1350 made in

total so it is going to be a hard job trying to trace them all! Funny, my Olympic

suffered a front suspension failure in the '70s at Newark....

Malcolm writes: It sounds like a

really nice, well looked after GT, I wonder what happened to it after you sold

it? There's nothing on DVLA for SVN 168, either under Ford or Rochdale... The

registration dates from July/Aug 1958 (in the North Riding of Yorkshire),

making it (if it was registered new) a relatively early GT on the road. With a

tuned engine and 15in wheels, I suspect you had oversize tyres, because they

look pretty big in the photos, to help the gearing maybe...Do you have any more

photos? It would be really good to see better pics if possible, and to use them

in our club mag too. Do you know the names of the people you bought it off or

sold it to or any subsequent history?

Ray writes:Sorry but I have no

information on the previous owner or on the person I sold it to other than they

were in Teesside. The photo you have is the only one available, I did not take

any more. It is me in the background. You can use it in the Club Magazine if

you wish and add the limited history I have given. If I find anything I will

forward it to you. It is best to avoid the Newark area as it is not good for

Rochdales.

I look forward to seeing you all

at the AGM

James

Being set up

Or how to get the best out of your

Rochdales cornering ability.

Study the photograph carefully.

What do you see? An E type cornering to perfection. The cars nearside wheels

(right as you look) are taking virtually all of the load of the cars cornering

forces, so giving the maximum grip; the wheels themselves being vertical while

the offside front wheel is just pawing the ground.

The car is neither under-steering

nor over-steering, in fact the attitude of the car shows that it has been set up

perfectly. Such settings would allow this car to be driven up to the limits of

its tyre grip and road surface adhesion. Consequently, the driver could not

gain any further cornering ability unless changes were made to such items as

the type of tyre used and width of tyre/wheel combination. If a car is not able

to fulfil the above requirements it will not be able to corner as quickly, for

the driver will be wasting time making steering and possibly power corrections.

So how do you set up a car like this?

The answer is by experimentation,

a long tedious job, but we can start by employing timehonoured methods and

pursue a logical path. The variables are the suspension geometry, the springs,

the dampers, the tyre pressures, the anti-roll bars, the roll centre height and

even the centre of gravity.

The latter is pretty well fixed

with the general layout of the car. Such items as batteries are often mounted

unnecessarily high up under the bonnet when a lower setting would be much

preferable. However, the C. of G. of the car can be lowered by shortening the

height of the springs but this will alter the rate of the spring and we can

only lower a certain amount to ensure that, for road cars in particular, there

will be no bottoming with bad roads, heavy loads or both.

Additionally, where our

front-engined cars are concerned a 50/50 weight balance is desirable and again,

a positional change of that aforementioned battery may help achieve this

balance. I have found that the local council weighbridge will allow ones car

to be weighed free of charge (not so where I live -Ed).

We are pretty well stuck with the manufacturers suspension

geometry and unless it is a car with a known history of poor handling, it is

probably best left alone. There could be a case for a change to the caster

angle assuming there is no other problem with the steering such as partial

seizure of ball joints or stiffness in the rack. Then again, if the car feels

nervous on the straight and requires constant wheel correction, or if the

steering wheel is too slow to unwind after a corner, then there is a good

chance that a greater caster angle may be required. It could be that just one

more degree would be sufficient. For track days or racing static wheel negative

camber should be set such that when cornering hard, the wheels remain upright.

For road use too much negative camber can give rise to straight line

instability so keep below 11/2 degrees.

Adjustable dampers will need to

be stiffened up a little for fast road driving and a lot for track driving but

variations between front and rear could help to get a better balance for

cornering. For example, much stiffer rear dampers than front ones could well

help to add a degree of over-steer. As to the springs, which, like the dampers,

would normally be stiffened quite dramatically for racing, on a road car, too

much stiffening would ruin the ride, so such a small required amount of spring

stiffening could probably be ignored and car tautness retained solely by the

damper stiffening mentioned above.

Tyre pressures for track use need

considerable experimentation, the aim being to have pressures high enough to

ensure there is no tyre deformation with hard cornering but not so much as to

give tyre patter which will reduce grip. I have found track pressures have

required increases as much as anything between 25-35% over comfortable road

pressures. As with dampers, fine tuning for the handling can be had by varying

the degree that tyre pressures are increased between front and rear. Too much

under-steer ?- add more pressure to the front and reduce a little to the rear

tyres.

That leaves anti-roll bars and

roll-centre height. Most road cars keep roll to a minimum with their designed

suspension geometry but press-on drivers tend to feel that their cars roll too

much. The simple cure is to fit stiffer, (thicker) anti-roll bars back and

front which will not spoil the ride qualities of the car. There is a tendency

for manufacturers to keep the anti-roll bars fairly weak. The reason for this is

twofold. Firstly, too stiff a set of anti-roll bars will cause lateral rocking

on uneven surfaces and secondly, manufacturers are happier to play safe by

giving the less experienced driver an earlier warning of danger when cornering

at speed. Some time ago I did experiments to see why my car had a tendency to

roll up to a point on entering a corner and then feel as if the roll was fully

checked. I soon realised that the anti-roll bar rubber clamps had deteriorated

and fitted a new set. This certainly improved the feel of the car but it was

not until I fitted poly bushes to the anti-roll bar did the car feel absolutely

right when turning into a corner at speed. Any change in roll-bar diameter when

you are fine tuning should be kept to a minimum for it must be realised that

roll-bar stiffness varies to the fourth power of the diameter.

The roll centre height is a

product of the suspension geometry and to alter this height would involve major

changes to the suspension mounting points, not to mention the position of the

rack and pinion. Consequently, this article cannot go into the whys and

wherefores of this specialised subject, suffice to say that road cars are

unlikely to ever need to be altered.

Returning to the issue of

dampers, it should be pointed out that they have little effect on weight

transfer during steady cornering - unlike anti-roll bars. Their only effect is

during transient motions. For example, during the period when the car is

changing from straight-line motoring to taking a curve. The increase in the

availability of poly bushes has led to many enthusiasts fitting them to their

suspensions but this has inevitably led to harshness, not a problem for race

cars but hardly acceptable for road cars With a rear live axle it is therefore

advisable with a road car to fit poly bushes to just one end of the locating

arms, using the manufacturers rubber bushes at the other end. This allows for

some compliance in the suspension as when traversing unduly rough terrain.

I'll conclude by adding that suspension

modifications can only be undertaken sensibly on a track away from todays busy

roads and with corners on circuits that can give direct comparisons of handling

with each modification. The whole issue of suspension and its setting up of a

car has to be a compromise of all the parts involved.

Derek Argyle

Changing Times

I wouldn't say that I was that

old but I do remember when drivers were fat and racing car tyres were thin. I

remember when we had service station attendants who would fill your car and

clean the screen as part of the service. Then there were the courteous AA and

RAC service patrol men who would give you a salute if you carried their badge.

The great motorcycling fraternity would always stop for another in trouble on

the road and even stop occasionally for a motorist. As relatively poor as we

were in those days we never gave a second thought to the cost of petrol though

it must be admitted that we didn't have the fuel guzzlers we have on our roads

today. How times have changed.

In my youth roads had relatively

little traffic on them and of course there were fewer roads and certainly no

motorways. Those were the days. It is still possible to find a few such roads

in this country but invariably they are in the wilds and far from southern

England. The nearest I can get to the deserted road is to be found on the

trips the Club takes to France. Not only that but what roads! Travelling on

secondary roads the surfaces are a delight; so smooth the Special feels as if

it's value is worth twice as much with the delightful ride and silence. One can

often drive for half an hour and not see another vehicle.

Car servicing years ago was not

unduly expensive and invariably one received a job well done. How times have

changed. I do not work on my Vauxhall Omega and leave servicing and MOTs to a

friendly mobile technician. On the odd occasion when I have had to take the car

to a Vauxhall dealer the work has cost me a small fortune.

One of several reasons why I

retired early was because of the bad standard of driving on my journeys into

London. Last minute cut-ins, V signs and general aggression during the morning

and evening rush hour was a situation I felt I could well do without. And so I

retired four years early and did the only thing that any self-respecting

engineer should do - build a Wildcat kit car. This abysmal standard of driving

just did not happen in my early days of motoring and there was even time and

opportunity to look at the scenery. Perhaps I am getting old after all

and should appreciate the changing times.

Derek Argyle

Rebuild of Phase 1 279CWD repairing the roof

Alan Farrer

Having completed the structural

repairs to the bodywork I was left with the roof. This had a good shape but

was covered with nasty looking crazing (aka cracks); either the car had had a

rollover or it had been used as a shelf during its period of inactivity. I

baulked at the thought of grinding them out and filling them individually

(wouldn't you?) and anyway there were also the usual trillion or so pinholes.�

Having spent much time wielding an artists brush and filling them individually

on my Phase 2 this was something I wanted to avoid this time round.

The accepted remedy is to clad

with tissue. I have tried this in the past and have been unimpressed by the

process; tissue is very fragile so can't be applied in large sheets and doesn't

conform to complex curves. As an experiment last year I used some fine glass

cloth I happened to have to cover crazing on the back of this car; this went

well, even though I had not really planned the process properly.� With a layer

of laminating resin applied and rubbed down the finish was quite good � and

pinhole free too.

Thus I planned the roof rather

more carefully. First of all I rubbed down the whole surface to remove old

paint and provide a good key using an orbital sander with a coarse grit disc,

then filled the few small depressions using normal body filler; even though

these were not visible they were easily felt by hand fingers are very

sensitive.

I calculated that the cloth I had

used on my experiment was about 120g/m, so something between that and the

30g/m of tissue should do the trick. Googling glassfibre brought me to East

Coast Fibreglass Supplies (ecfibreglasssupplies.co.uk) who cater largely for

the boatbuilding trade and have a very comprehensive stock. They stock a plain

glass weave at 48g/m and, even better, stock it in 1.27m (50) width, which

nicely covers the Olympic roof with 3" hanging over each side, so no joins. I

ordered 5m, thinking it would be useful to cover other areas too. I rather

feared it would be supplied folded, but it arrived very comprehensively packed

on a cardboard tube, protected by acres of bubble wrap and in a stout card

outer case. I can recommend this firm.

This is a very light cloth so is

easily damaged. I very carefully cut off 1.5m using a sharp craft knife and

laid this on the roof, which I had cleaned of debris using a vacuum cleaner

fitted with a brush tool. I smoothed it down gently by hand to get it to lay

with no wrinkles and finished off with a paint roller.

Next question: how much resin?

300g CSM needs about 600g/m, so 48g would need about 100g/m. The roof area

is nearly 1.5m, so 150g would be needed. I allowed 50g spare and measured out

200ml, forgetting resin is much denser than water, so I had plenty over! 150ml

would have been plenty. I measure resin by pouring it from a rectangular PVC

bottle which I calibrated by simple measurement, marking 100ml divisions on the

side with a marker pen crude but simple. I also measure out the hardener

using one of those tiny graduated beakers available for that purpose. 2% is

about right.

I always use pigment in my mix as

this gives a better match to the original and as a bonus indicates when the

tools are properly cleaned. I also use a roller rather than a brush to apply

the resin as this squeegees the glass material (eg CSM) with no real need for a

metal roller. A brush tends to drag the fibres, which would damage the fine

cloth I was using, another reason to use a roller. I use the small decorators

lambs wool type. Incidentally I clean the roller by scraping off the worst

with a blunt knife then, letting the roller hang vertically, pour acetone over

the end. When this starts to trickle off the bottom I hold the roller in the

bin and spin it vigorously with a stick to centrifuge the liquid off. A couple

of repeats and the roller is nearly as good as new; barring accidents (resin

has set!) a roller can be used many times.

Starting at the centre I applied

resin in a strip from front to back to lock the sheet in position, then worked

out to the sides, taking care avoid creasing the cloth (not very difficult). I

even managed to fold the cloth under the sides to seal the edges.

When it had cured I could see

that the crazes had sucked the resin from the cloth in places (I should have

been more generous). A second coat of resin fixed that problem but it did set

me thinking, so I repeated the exercise with another layer of glass, just to

make sure. It's no good having regrets when cracks reappear in a year or so,

when it's much harder to put it right. This time I used a sponge roller, as

the lamb's wool one was getting tatty, and the final finish was nearly as good

as some of my painting (says something for my painting skills). However the

sponge roller is much harder to clean so was discarded.

I would recommend this procedure

for anyone with a similarly crazed roof or other panel (I also treated the

bonnet and a crazed part of one door) it's straightforward and easy, provided

one plans the job and takes care. No more pinholes!!

48gm glass cloth in place

Resin applied

good finish guaranteed!

This

was the damaged rear that prompted the idea of cladding with cloth. Once

repaired and filled, cloth could easily be persuaded to conform to the

complex curve unlike tissue.

Stainless Steel Window Frames for the Olympic

Phase 1

Alan Farrer

Having rashly mentioned this

activity in mag 120 and having had a rare response, I felt obliged to oblige,

though Derek Bentley also wrote a very full article on the same subject in mag

82 using welded joints. Here is my version using bolted up joints.

Although the title refers to the

phase 1 the only real difference between the phases is the way the front down

piece fits to the door. In the phase 1 the down piece stops at the top of the

door whereas in the phase 2 it continues down the outside of the front of the

door. Later phase 2s also used a wider section in the aluminium extrusion to

give a much stiffer frame. However, the Morris Minor steel frames are much

stiffer still, which is why they are a popular mod on Olympics.

First find your donor frames.

These come from the 2 door Traveller; those of the 4 door are shorter about

2 too short for the Olympic, though a good welder could add the necessary

piece. Now remove all the screws and keep them for reuse, together with the

corner angle brackets (assuming they are reusable as they are not stainless

they may well be too far gone, or the screws may well have rusted in and need

to be drilled out). Strip off all the brackets which are spot-welded on. I

did this by cutting either side of each weld to remove most of the bracket,

then filing down the stubs. This is a tedious job.

Now comes the tricky bit:

re-shaping the top section to fit the Olympic. Mark your two pieces L & R

as the shapes will be a little different on the two sides. The bending can be

done cold, but much more force is required and an increased danger of buckling

than if heat is used. Also, heating enables the place where bending is

required to be better controlled.

A bending jig is essential to

avoid buckling. I made a crude jig using two sheets of 3mm mild steel bolted

together and spaced apart by a piece of chipboard of the correct thickness

(20mm). One corner of this chipboard was cut to a curve of smaller radius than

the required bend. The wood was protected from the heat by a strip of ali

wedged in place. A detachable stop was fitted to the steel take the bending

torque, so that both hands could be used to control the bend, and the jig was

mounted in a vice (see picture).

Offering the frame up to the door

aperture (with door in place), I marked the frame where the bend was to start.

I arranged this so that I did not have to cut any material from the front of

the frame, as there is not a lot of spare. I then heated the frame with a

blowlamp to a red heat over a length of 6-8" (a sheet of refractory material

behind the frame speeds things up), whacked it in the jig and gave it a heave

(gloved hands!). I had prepared a template for the required shape and got as

close to this as possible before the frame cooled (which is quickly, as it is

in contact with the steel of the jig). By offering the frame to the door

aperture I could see where adjustments were needed and repeated the process

until I was satisfied with the shape. The excess at the top rear was then cut

off at an angle to match the 45degree angle of the rear upright. Note that the

included angle is a little under 90degree. I also filled the four remaining holes

with weld, although short countersunk screws could have done the job, albeit

less neatly.

Heating the steel rather spoils

the shine, so when it had cooled I buffed the surface using Scotchbrite which

left a rather pleasant satin finish, and treated all the other pieces to match.

Bending jig crude but effective

The main reason for using the

Minor frame is stiffness so that the frame can compress the door seal over the

whole length and prevent wind noise. In the Olympic design this is provided by

two sections: the rear vertical and the centre vertical, which are welded to

the top curved piece. The latter provides no bending stiffness, since it ends

at the door, so the weld in alloy frames tends to fracture here.

In my design I decided to use a

bolted-up design to avoid welding, which makes removal easier too. Some

stiffness is lost by not welding, but by extending the front section downwards

by 6" and screwing this extension to the front edge of the door stiffness is

restored (and possibly increased). I made this extension from 2mm stainless

about 200mm long and 15mm wide so that it fitted snugly inside the channel and

screwed it to the channel using a pair of M5 CSK screws and Nylok nuts. A slot

has to be made in the horizontal top of the door for this extension to pass

through so that it can fit to the inside of the sloping front of the door. The

extension was drilled and tapped M5 at two points, one close to the top and the

other close to the bottom. By careful measurement two corresponding holes were

drilled in the glassfibre to take the screws (M5 SS, domed head, hex drive).

It is difficult to get the correct angle so that the frame compresses the

rubber seal to the right degree, but by slotting the lower hole of this pair

enough adjustment was achieved.

The two vertical channels that

guide the glass have to be spaced correctly this spacing differs by about

12mm between left and right sides. The glass shape is different too. I found

that the shape on the passenger side was a better match to the door frame, so

used two left hand glasses. First I cut the rear upright channel to the

required length, with a chamfer at the bottom to allow for the curve of the

outer door skin. I used an original MM angle bracket at the top to join it to

the top rail, though a new one in stainless steel would have been better.

In the original Rochdale design,

the rear upright is fixed to the door via two welded-on plates, one at the

bottom and one at the top of the door panel (about half way up the channel). I

did not use a top plate as the channel is a good fit in the slot at the top of

the door, which has to be widened locally to fit the MM channel. I pop-riveted

a 2mm SS plate at the bottom and tapped it M5 for the lower screw. Care needed

to be taken to prevent the pop rivets hitting the glass at its lowest position.

Getting the correct place for this screw is tricky, as the moulding in the

inner door panel is not really big or flat enough for the purpose (what's

new?). The correct angle to ensure the frame compresses the seal was achieved

by packing between the fixing plate and the moulding.

The riveted-on piece which makes

a seal to the B pillar is very similar to the Olympic version, and one could

indeed use the original, but I used the MM version. This is rather tricky; as

stainless steel is not very malleable. The lowest rivet needs to be removed,

then the sheet carefully walloped to get it to match the contour of the door

and the excess trimmed off. A single self-tapper held it down. A similar

screw (and friends) seems to have been used in the past to secure the frame to

the door; this was a waste of time as it simply worked loose in the thin

glassfibre.

To fit the front upright I

carefully measured the width of the glass, added enough to allow for the window

felt and the thickness of the channel steel, and marked the door top where the

slot had to be widened to fit the MM channel.

The required length of channel

was then cut from the original MM channel, allowing for a chamfer at the bottom

to fit the slope of the door outer skin, and an extension at the top to bolt to

the sloping piece of channel to make up for the stiffness lost by having no

weld. This was made by cutting off the sides for about 40mm and bending the

strip in a dogleg to meet the sloping piece. Getting it to fit neatly was a fiddly

job, but for a retiree like me was worth the time spent. As at the rear, there

was only a fixing at the bottom, using a pop-riveted plate tapped M5 for the

fixing screw. The original MM triangular plate which covers the joins can be

used, with a little cutting, even though it is a little small.

A note on fitting the window

winder. The inner door panel seems to have marks to indicate the position of

the four fixing screws for the mechanism. Unfortunately, this results in the

mechanism being fitted parallel to the top of the panel, whereas it needs to be

fitted so that it parallel to the top of the door; the window is then not

canted and slides properly. Slotting the original fixing holes will probably

allow enough adjustment.

Another note on the steel channel

at the bottom of the glass. This may well be rusted out, but may be replaced

with that from a MM, even though that car uses much shorter channel. Two

pieces about 125mm long will be sufficient; this is just long enough to prevent

the wheels at the ends of the arms falling out at the bottom of the travel,

provided they are carefully positioned.

A third note on window glass. It

is perfectly possible to use acrylic (Perspex) instead of glass. It scratches

more easily of course, but Derek Bentley has used it for 25 years and I used it

on my Phase 2 to good effect. It has the merit of lower weight and can be

profiled easily to get a good fit to the door frame. It needs to be the same

thickness (5mm) as the glass.

Complete

frame with corner details (inside view of drivers side) NB Chamfers at bottom

of verticals not visible in these pictures. The screw shown inset is a

bottom stop for the glass.

How I Got my Rochdale

James Wilson

After reading stories about how

other owners came by their cars I thought my story might be of some interest.

Way back in 2001 I'd decided that all work and no play was not fun, and that I

should revive my involvement with old British sports cars. I'd had a '64 MGB

and a '73 Spitfire many years ago when they were just old, used cars and not

classics. And when I first moved from the USA to the UK in 1984 I thought it

would be an ideal opportunity to get something interesting. But between

settling into my new job, buying a house, having and raising a child, moving

house and the myriad hassles of life generally that idea was pushed to the back

burner. But in 2001, it was time.

So I bought a Big Healey project

(still working on it, with another two years to go on what I'd thought was a two-year

project) and imported it from the USA. I joined the Austin-Healey Club and

went off to see the local group at a car show in Callander. And that's when I

first saw a Rochdale Olympic. It wasn't quite love at first sight, but close

There were two just sitting in the field being used for parking. I looked at

it very closely, peering through the windows and having a good snoop. But the

owners were nowhere to be seen, and the cars were long gone when I came back

from the show. The Olympic had made quite an impression on me, and I found out

a little about them over the next few years; and I irregularly followed Malcolm

MacKays column and published exploits. I also picked up a few articles about

them, but I never, ever saw another one. In the meantime, I also acquired a

Jensen-Healey (given the Healey Connection it wasn't too hard to do) in 2006

and started on a rebuild of it. Late in 2007 I thought I was finishing the

Jensen (Ha!) and could look for something interesting again and the Rochdale

Olympic was it.

I did some more research and

became very interested in getting one. I joined the Rochdale Owners Club

despite not owning one and started gathering information about them, buying all

the back issues of the Club magazine and tracking down (it's remarkable how

useful e-bay was for that, as well as a specialist book shop, or two) as many

of the articles about it as I could find. The Club gave me the contact details

of an owner, Ron Collins, in Edinburgh but I didn't pursue that any further

until January, 2008. I then felt I knew enough about them to ask

semiintelligent questions and look at one without seeming entirely ignorant;

and I felt that I could seriously speak to people about buying one in a

reasonably near future. I had earlier looked at one advertised in the Club

magazine but it was much too big a project- the front cross-frame was rotten

and the body needed considerable work. This quick look also proved that I

really needed to talk to someone knowledgeable about the cars - the big

problems I could see, but the subtle and little things to look for would need

an experts input.

So I contacted Ron, and went over

to Edinburgh to see him. We had a long talk about his car, and my assorted

automotive interests and experiences with rebuilding the Healeys and his

rebuild of his car some years previously. I was almost being vetted as a

potential owner, I felt. One thing lead to another and I soon discovered his

car had just been put up for sale. The club magazine hadn't yet appeared so I

was there before any "rush" started and we had an amicable chat about

his selling it to me, then a look over it and a very short drive; and soon

concluded a deal where I acquired his car.

I think Ron very much wanted his

car to stay in Scotland, and to be used rather than sit in a garage. We agreed

on a fair price and the deed was done. Pretty painless, and a great deal less

searching and inspecting cars and challenging projects than I'd previously

imagined. And, unlike my Big Healey or Jensen Healey, it was in good condition

except for a few minor cosmetic and general maintenance chores. Ron was unwell

at the time and has since died, but I was able to let him know his car was in

appreciative hands, and tell him of my adventures in taking it through the

Highlands and over to Skye.

I've used it a fair bit for local

drives, and for the annual Scottish Austin-Healey Club weekend tours. I think

I'll join another local club or two and try to get out more with it. It always

gets an appreciative look wherever I take it, and people just smile when they

see it. I'd like to get to the AGM, but we'll see

I've made plans for improving it

- I've already fixed a couple of minor problems, and I expect to redo the seat

covers, carpets and headliner by summers end. Next winters project is to fit

an MG Metro turbo to the 1275 BMC A engine it has, and figure out how to fit an

overdrive transmission to that. My Olympic (and other adventures) can be

followed at my website:

http://www.healeyjournal.com/pages/rochdale.html

This describes my car, what I've

been able to find out about its history, a comprehensive listing of articles

published about the Olympic and some of the books that have commentary about

it. I also show many of the promotional materials and advertisements about the

Olympic and some of the other Rochdale cars. If anyone knows of books or

articles or promotional material, I'd much appreciate they're telling me of it.

I found the idea of owning two of

the most innovative British sports cars amusing: The JensenHealey with its

ground-breaking dual overhead cam four valves/cylinder engine, and an Olympic

with its one-piece moulded fibreglass monocoque body. And the Big Healey is

one of the iconic British sports cars. It's a very small, but highly select

collection. And I'm very proud and pleased with the Olympic; and hope to use

and enjoy it for years to come.

Overlooking the Mull of Galloway,

May, 2009. The most southerly point of Scotland.

Fitting a Phase 2 Subframe the Russ Collins

way

After reading Keith Hamers

article in issue 120 of the magazine I thought I would add my two pence worth

having been through this process where many agonising decisions have to be

made. I do not profess to be an expert on suspension design but I did put a

lot of thought into the decisions that I made. I have listed these decisions

and the background to them so that others can reflect as they go through a

similar process. Remember that a jig was not available to members at the time

that I fabricated and fitted my Phase 2 sub-frame.

I first checked that my garage

floor was flat and level. I then marked on the floor a centreline with two

lines at right angles approximately where the wheels would be. I marked these

wheelbase lines at 100 mm intervals working out from the centreline. I set the

bare shell on this grid at the desired ride height. I took many measurements

to determine the true centreline of the shell but finally decided that a line

that fell midway between the outside of front and rear wheel arches was the

best compromise. At least the wheels would appear to be in the right place

from side to side. The fore and aft positioning is not critical at this stage.

I decided on a ground clearance of 140 mm at the front wheels increasing to 190

mm at the back. I did not want to fit a spoiler so reasoned that a slight nose

down attitude would help to compensate for the lift at higher speeds. It also

helped with clearances at the rear wheel arches.