MAGAZINE No 113 SPRING 2008

TONY STANTONS EVENTS PAGE

E-mail tony-stanton@fsmail.net

South Midlands Classic Car/Bike Meet No 1

The second Sunday of the month in the Winter, the second

Tuesday evening of the month in the Summer, at Britannic Assurance,1 Wythall

Green Way, off Middle Lane, Wythall, Birmingham, B47 6WG (From J3 on the M42

follow A435 north 1-mile turn left at 1st roundabout then mile turn left at

mini roundabout).

Sunday 9th March, 11am till 3pm.

Sunday 13th April, 11am till 3pm

Tuesday 13th May, from 7pm.

Tuesday 10th June, from 7pm.

I did not go to the meetings in December and January

as both Sundays were wet, windy and cold. But Sunday the 10th February was a

lovely warm, sunny day and a good turnout of about 230 cars and bikes. As I was

about to leave I met Chris Burton who I have not seen for over 15years; he

still owns Olympic P1 reg 2341 N and it is safely stored in his garage awaiting

a rebuild, the main problem is a collapsed front subframe.

On my

way home I called in to the barn rented by Mark Butler; it is like walking into

a 1960/70's garage. It contains Marks 2 Unipower GT, s, a Rochdale Olympic, a

Ginetta G15, Marks partner Angelas Lotus Elan +2 and his mates Lotus Europa

- a real fibreglass heaven.

Not a

lot on at this time of the year, but on Sunday 17th Feb, DUFFY and I drove the

120miles down to the Bristol Classic Car Show and spent a very pleasant day in

the company of Derek Bentley, Nigel Whittaker, Alan Farrer and Guy Stallard.

South Midlands Classic Car/Bike Meet No 2

The last Thursday of the month in the Summer at The

Moat House Inn, Birmingham Road (A435), Kings Coughton, Alcester, Warks, B49

5QF

Starts on

Thursday 24th April, from 7pm.

Thursday 29th May, from 7pm.

Thursday 26th June, from 7pm.

Stoneleigh Kit Car Show 4th & 5th May 2008

Just

to let you know I have reserved stand Number 39D for all HISTORIC SPECIALS

AND CLASSIC KIT CARS built before 1973 at the N.A.C. Stoneleigh Park,

Warwickshire, for every kit car enthusiast with old

or new kit cars. Sunday 4th and Monday 5th of May 2008, from 9.30am till

5.30pm. (May Day Bank Holiday weekend)

All kit car drivers are admitted free of charge, passengers

are1/2 price.

You can camp on the site, tents and caravans, please

contact the organisers office 01775 722900 for details and forms www.grosvenorexhibitions.co.uk

This

is a very good cheap day out, spares are cheap, where else can you buy brand

new crossflow radiators for £15 to £20 and new electric cooling fans for 5?

(ask Alan, he went away with a car full) There are 5 large Exhibition Halls and

600+ Trade Stands all the things you need for your rebuild or update. You can

look at new kit cars in rolling chassis form indoors in the dry and warm which

will give you ideas on suspension, brakes and drivetrain modification for your

car.

This

is the best show of the year for kit car engineering. Come to the main

vehicular entrance which is located on the B4113, the Coventry to Leamington

Spa road (follow signs for clubs and exhibitors (do not go into the Public car

parks). It is only 2miles from where we have the A.G.M.

PLEASE tell everybody you know with a suitable car and

place details on websites if you can

WITH CAPESTHORNE NO MORE, LETS HAVE A GOOD TURN OUT OF

ROCHDALE CARS AT

THIS EVENT INSTEAD. Last year of the 11 cars I had

on the stand only 4 were Rochdales, so please make the effort to bring your car

this year.

Contact Tony Stanton (Rochdale Olympic 902DUF). tony-stanton@fsmail.net

SILVERSTONE

CLASSIC on July 25th, 26th & 27th 2008.

In

conjunction with the F.S.C.C. we have secured a designated display area within

the Historic Grand Prix circuit at this 3-day event, and we are seeking further

club marque cars to join us on display during the weekend. Last year on the

stand we had 2 Olympics, 1 Fairthorpe and 7 Turners plus 2 more Turners racing,

so let's go for more Olympics this year.

Featuring

22 races, 800+ competitors, and 600 of the most valuable racecars and

motorcycles in the world. On top of the mouth-watering line-up of races

lasting between 20minuites and 1hour each, starring the very best

single-seater, GT and Touring Cars from the past 80 years, the entire infield

will be packed with more than 4000 classic cars showcasing in excess of 50

famous marques. There will also be a period funfair, air displays, trade

stalls, live music, barbecues and more than 30 hot air balloons are set to fire

up for their traditional morning and evening fly-outs.

DUFFY

and I have been to this fabulous event for the last 3 years and I think it is

better than Goodwood. You can walk around the paddock and in the pit garages

at any time, talk to the drivers, watch the mechanics working on the cars

close-up and just to wet your appetite the last race on

Saturday

is a 90 minute race for Sports Racing Cars from the late 60's (i.e. GT40s Lola

T70s and Chevrons) racing into the dusk with their headlights on, so be there

with your marque car you are going to love it (ask Derek and Alan).

To enter your club car in the FSCC/ROC display area please

contact Tony Stanton on tony-stanton@fsmail.net and I will issue the

club reference number to quote when booking tickets and Marque car passes.

There

are changes this year in the organization. All club members can use the code

for discounted tickets whether displaying a car or not! I understand unlike

2007, car passes will be sent WITH the admission tickets to those who are

displaying so be sure to advise this when you book.

ROCHDALE CALENDAR 2008

It is

with disappointment and frustration I write a report on the 2008 Calendar. Of

the 100+ R.O.C. members and 30 cars on the road only 8 members sent me

photographs of the 12 I needed and I find it difficult to believe only 28

members purchased copies at the low price of £6 inc p&p. If the calendar

had been printed by Tesco or Jessops they would have cost the club £12.95 each

to sell at what price?

Now if

the members would like a calendar for 2009 I need 12 new photos, of good

resolution around 1MB and a nice interesting background. I need the photos

soon so the calendar is ready for sale at Burford in August, the NEC and

Christmas. Post them, E-mail them, bring them to the A.G.M.

NO PHOTOS - NO CALENDAR

And a little note to end on:

You polish yours and I'll drive mine

Not

one for the calendar

Bristol Classic Car Show 16th/17th Feb

2008

Our stand was in the same position as last year, but

thankfully the cow smell was absent. Although nominally the same size too the

partition seems to have been placed to give us another 1-2m of width. This

was nice, but as it turned out we had only one car to show Fred Blackmores

fine white Phase 2 Olympic, as Nigels equally nice turquoise Phase 1 suffered

a last minute problem and was absent. Had I known we had so much space I would

have had three cars (down to two).

Freds car looked a bit lonely, but this meant it was in

full view and attracted a lot of attention. It also attracted a Highly

Commended rosette from the shows sponsor, Footman James. It's nice when your

efforts are rewarded, isn't it Fred? Saturday was very busy, though Sunday a

bit quieter.

As always exhibiting at this show is a pretty relaxed

affair, aided this year by fine sunny weather. As always, the hall was

coooold. Again the organiser made available a room for a committee meeting on

the Saturday morning, which just indicates what a friendly show this is, so

many thanks to Josette.

Special thanks are also due to Derek, who did all the setup

for me (aided by Nigel) as I was attending a family do (my father-in-laws 90th

birthday party) which I certainly did not want to miss, and to Fred, of course,

for providing his car. Thanks too to Tony Stanton and Guy Stallard who manned

the stand on Sunday.

This is a nice show, very friendly and a nice size, so why

not come along next year just remember to bring your thermals if you intend

to stay for any time on the stand (though it's warmer in the larger halls).

Alan Farrer

Highly

Commended

Dashboards. From top: Robin Strettons Phase 1, Roger

Drinkwaters Phase 1, Alan Farrers Phase 2

S T S T O R Y

Back in last August my GT was left outside the local garage

in Hemyock awaiting its MOT test. Normally this is done while I wait, with much

chatting to the garage owner who does all the classics. However, on this occasion

he was very busy so all I did was run it up on the brake rollers and leave it

on the ramp for him.

A retired local builder turned up to fetch his car and

commented to the garage owner that the GT looked like a Rochdale. The somewhat

bewildered garage owner wondered how he had recognised it, and was told he had

once built one in the fifties and asked who owned the GT.

When my name was mentioned, the builder, Richard Hart now

aged 69, said what a coincidence this was as it was at my farm that he had

built his Rochdale. Now I had heard that Mr Hart had built a special in a

disused pig-stye at Culm Pyne but it had never been mentioned what sort; I had

assumed a modified Austin or such.

Some of Mr Hart's recollections are somewhat vague now,

bearing in mind it is some 50 yrs since he built it. It was purchased as a body

kit, probably in 1957, having been seen in a magazine or newspaper. The model

was a ST, as he could not afford the extra forty quid for a GT, and it was

ordered direct from RMP. It was a bit of a bargain as the price had been

dropped from £100 to £85, the moulding being less than perfect with plenty of

blow holes in the gelcoat. The shell was delivered by lorry to Culm Pyne but Mr

Hart could not remember if it came direct or by train to, say, Taunton first.

The reason it had come to my father's farm was that Mr

Hart's brother-in-law worked on the farm as a farm-worker. The brother-in-law

had given Mr Hart an old Ford 8 van in return for painting part of the

accommodation. Mr Hart's family firm were builders in the village and, aged 19,

this was an ideal swap. My father had an unused pig-stye adjacent to the van

and allowed Mr Hart to do the build there in return for a bit more painting.

The ST was built up by Mr Hart and some of his friends. The

original van engine turned out to be no good, so another one was obtained. This

was fitted with a skimmed high compression head with "racing valve

springs". A 1". exhaust pipe was made in copper by his Dad's firm's

plumber. Many of the parts were obtained from Isaac's scrap yard in Dunkeswell,

now long gone. A mate, Colin Mitchell, who was a garage mechanic, did the

wiring using a purchased loom and the hood was made in Taunton.

Hemyock's local garage owner, Stan Doble, whose Dobles Garage

still trades but under different ownership, supplied much needed help and

advice with generous access to the stores. The car was sprayed at the garage,

in light blue originally, but did not look very good due to the poor shell

quality. Mr Doble then sprayed it dark blue with a white stripe and it looked

much better. Later still a white stripe over the wheel arches was added by a

friend using a flit gun sprayer as used for spraying DDT. Mr Doble also handled

the paper work and on his advice it was called a 'tourer' and not a'sports car'

in order to reduce the insurance costs.

On its first outing to nearby Wellington the car lost water

due to the fan catching the lowered radiator's hoses. On the return, up the

long steep hill, the engine boiled due to insufficient water circulation. Mr

Hart didn't know what to do until he heard of another ST owner about 10 miles

away in Willand, who told him to fit a Ford export water pump. This was duly

done, to no avail, till the local garage brazed an old penny into one of the

two outlet holes on the pump. This promptly cured the problem.

At a later date the car was fitted with twin SUs which then

apparently made the car faster than the suspension and local roads could cope

with. The carbs came off an old car which was then abandoned in the builders

yard. Mr Hart gave me the remains of the chassis when I was about 16 as I was

interested in it as a special. However, it was too far gone and eventually I

identified it as a 1930 M type MG which I sold to a ferry captain in Sweden who

has since fully restored it. What a co-incidence!

Mr Hart sold his ST after a couple of years to a man, also

from Willand, for £250 and nothing has been heard of the car since.

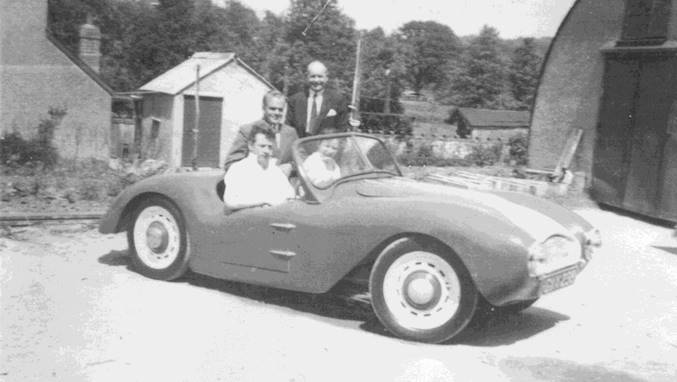

Richard

Hart back in 1957

Those were the days

* * * * * * * * * * * * * * * * * * * * * * * * *

RE-SPRAYING with AEROSOLS

What? Would anyone of a sane mind do such a thing? Every

now and again it is possible to see pictures in magazines of cars which the

owner has, apparently, sprayed with aerosol cans, and most folk are left

shaking their heads in disbelief rather than admiration.

On buying my Olympic back in 2000, it was apparent that the

metallic blue paint which had been applied in 1980 had faded quite badly.

Determined to take my time on getting a decent finish I took it around to some

of the more reputable local refinishers. All were concerned with what looked at

the time like quite small gel cracks, and opinions varied as to how to tackle

these. Also the very tight fit of the doors to the shell (a Rochdale feature)

and the overhang of the rear hatch caused much concern. It was apparent that

none wanted the job, and suggested I get stuck into repairing the cracks and

evening up the panels before I began to think of spraying. One even took me in

the back of his garage and showed me an almost complete Elan which had been

prepared as a concours item for a customer at a cost of over £20,000 for the

bodywork alone. The inference was that I'd be mad to spend that on my Rochdale,

and I suppose he was right as the actual work would have been quite similar to

that on the Elan.

Well, seven years of daily use on and the car still hadn't

had its re-spray. While reluctant to alter the panel gaps, it was apparent

that, though tight, they were far from even with signs of rubbing here and

there. I eventually took the sanding block to them, and though now wider they

are much more even and look better as a consequence. Rear hatch was a real

problem as its rear edge hung out about a quarter of an inch from where it

should. Move it all forward one of the body men had said, but the way the

tiny rose joints were mounted didn't allow for this, and there was very little

extra space at the front anyway. I eventually concluded that the hatch had

always been a bit too big for the space and sanded the excess off, allowing a

tighter fit on the catch.

But what about the spray? This was one of those jobs I had

very little experience of, most of my past refinishing being done with coach

enamel and a brush. My Commer (1967) had been finished like this from new and I

had elected for the same approach (Carnival Red, RePaint) for the school GT.

However, I had wanted to use a metallic finish for the Olympic and think that

even barely visible brush marks would stand out like a sore thumb on the

Olympics sleek lines. Most laymen looking for the first time think the GT a

nice old car, but that the Olympic could be almost new and where can I buy one?

Side note here: I always preferred Tekaloid but this is now down to just one

supplier in the country and in the last month or two local suppliers have given

up on RePaint as well. Are they trying to tell me something?

Supplies of cellulose are similarly limited, by law I

believe, my skills with the compressor and spraygun were minimal, and as I

wasn't about to fork out Elan-type bills that only left - the humble aerosol.

Main snags are, it can be an expensive way to buy paint, it's slow in

application and you have no control over the viscosity in the can. Plus points

are it's a safe system, no other equipment is required, the gun is always going

to work with minimal cleaning out, easy to perform in quite confined spaces and

you can conveniently divide the spraying into separate sections. Take your

time, be patient and aware of the problems, and the finish can be as good as an

expensive re-spray.

Here's some points worth considering:

1

Negotiate a price for the cans. You will be getting these in

large quantities - the dealer got them in specially for me - so you can expect

a substantial reduction. My wife beat him down to £2.50 per 300ml can of Astral

Blue and £3.00 for 400ml cans of primer/undercoat/lacquer. How many will you

need? A lot! I went back several times for more, but the full job came to less

than £150, probably less than for just the paint.

2

You can get aerosols specially mixed to any colour, which give a

more even spray than the usual Holts type. Yes, but for one can this cost me

around £14, so no prizes for guessing which I ended up using!

3

Don't skimp on the gel-crack treatment. I followed the Miles

Wilkins treatment as per the Osprey Restoration Guide. If I'd allowed the

proper time between coats I think I'd still be there now though! Similar stuff

on the club website, I believe.

4

The metallic effect is given by tiny flakes of aluminium in the

paint acting as mirrors. Care must be taken that in adjacent areas these settle

to rest in the similar directions. Instructions on the tin suggest first

vertical strokes, then a layer of horizontal, and so on. Sorry, I couldn't get

this to work at all - it ended up with a tartan effect. Best results were with

the paint runs delivered in one direction only - I opted for front-back runs

along the car for each panel, with runs overlapping by about a third in each

case.

5

Lacquer is crucial. T-cut applied to the metallics affected the

set of the aforementioned flakes and just didn't work at all. Once you have

covered the surface with an even layer of the colour there is little to be

gained by layer on layer, but you will need good layers of lacquer to work on

for the gloss. I was always told, incidentally, that it took SEVEN spray coats

to match one of brush, so take your time!

6

Look to the light lines. Some parts of the car are much more

important than others - the roof, the top of the wings, and, on the Olympic,

the whoosh lines. The entire car, below these lines, do not show to anything

like the same effect, so be prepared to pay particular attention to those parts

that reflect the light.

7

Adjacent panels can be blended in with care. The Olympic isn't

the easiest of cars in this respect - crikey, in what respect IS it the

easiest? - as there are no panel joins to use. If you spray up to a masked

edge, especially in metallic, it will show on the final finish. Also, if each

coat is to the same edge you run the risk of cutting through to the layers

below. It is better to mask well below the part you wish to spray to, then tape

a rough edge of newspaper a few inches up from this point to spray the primer.

Move the sheet back a little for the colour coat, then uncover more for the

lacquer - but NOT back to the masking tape, you will struggle to flat it.

8

OK, an aerosol doesn't generate anything like the mist of a gun,

but by the time you have put on 30 or 40 cans its pretty bad! Wear the proper

mask.

9

Paint runs. Two-stage solvents are used for Holts paints. The

first dries very quickly to stop runs, the second takes much longer and allows

the surface to even out and settle down. I only found this out after I had

finished the job! At any rate, if its going to run, it tends to do on the very

first layer onto the surface, so make this a very light one, and allow it to

settle for a good few minutes before building up the layers. Keep the gun

square to the surface, and not too near - 12 is suggested.

10

Finish - very disappointing, compared to the brush, but you're

only just starting when the paint goes on - elbow grease and T-cut is the order

of the day, and works wonders. Rub in the same direction throughout - it is

possible to damage the surface - and take care not to cut right through the

lacquer coat. Apply polish once finished.

11

Watch out for petrol (see photo). This was the result of one

particular fill a few years back. The surface had no lacquer, but I have

since tried petrol on unlacquered paint with no effect. Perhaps its just

certain blends of petrol? At any rate, the same discussion has been raised in a

bike mag recently, again citing Holts as the culprit. Still, I wasn't about to

pay £14 a tin, was I?

12

Badges. Vinyl cutters are coming more common these days, and I

cut a set of Olympic stickers in Silver to finish off. These are applied to

the rear hatch and back of the front wings, and are in Magneto font. They are

quite robust once on, but don't like being applied in cold temperatures. I

think the badges give a more professional effect, but on my very first drive

with them on, I was stopped to find out what sort of car it was! Hmmm....

How it's done; The finished article

In need of redecoration

Olympic badge in vinyl

* * * * * * * * * * L E T T E R S * * * * *

* * * * *

Hi Alan

Sorry I missed you at the Bristol Show. I was hoping to

take some measurements from the engine bay of your Zetez powered Olympic. I am

making progress with my restoration and attach some pics.

It is now a rolling shell so I am able to move it around on

its own wheels. I am quite pleased with the way it is shaping up. The rear

axle is a bit tight but I have some ideas to accommodate it. I had cut the

rear arches intending to flare them but am now thinking that I could ease the

shell out behind the wheel by a couple of inches so that they would not look

flared. I would like to keep the appearance of the rear as close to the

original as possible.

Fitting the front subrfame to the shell proved trickier

than I realised. I designed the subframe to sit in position with small

clearance from the front of the engine bay. The idea was to grind flat the

bits where the old subframe had been bonded, cut the fibreglass to form flaps

which could be moved in contact with the subframe, bolt it all together and

glass everything in to strengthen. I could not seem to get the bits flat enough

for my liking even with building up the low spots. I finished up cutting out

the entire front of the engine bay and making some flat sheets of glassfibre to

bolt to the subframe. I then glassed these to the body shell with a fairly

hefty lay up. This sounds straightforward but I had to make some curved

sections to make it all fit properly. It all fits quite well and the front

wheels seem to be in the right place.

Before I fitted the front suspension I decided to fit the

radiator while I had relative ease of access. The radiator is from a Lada

Samara and seems to fit perfectly the space available. It even has a built in

overheat fan and plumbing on the correct side for my engine. The rad mounting

has three rubber plugs. I glassed in a stiffener at the bottom to accommodate

the lower two and made an aluminium bracket for the upper one.

I have connected the Herald steering column to the Herald

rack with part of the column from a 1986 Ford Orion. This has two universal

joints at about the right spacing. I dispensed with the lower joint from the

Herald (going spare now if anyone wants it) and welded the spline bit from the

old Herald joint to the Orion column to make a direct connection to the rack.

The upper part of the Orion column has been welded to the Herald column inner rod

leaving everything above that as it was before.

Rear suspension is a five link live axle using a Fiat 124

design (manufactured by Lada). I cut the Fiat upper links and made them

adjustable so that I can get a decent angle for the prop shaft. I made up

front mounting points and strengthened the body shell where these are fitted.

The lower links are standard Rochdale and these fit the mountings on the Fiat

axle reasonably well. I did have to drill some extra holes to keep the rear

wheels in the right place. I also used the Fiat Panhard rod which fits just

behind the rear axle. I had to make a strong bracket and a bit of extra lay up

for this where it connects to the right hand side of the body.

The next job is to clean up and repair the body shell. It

is in fairly good condition compared with some that I have heard of. I want to

fill all the holes so that I can make a fresh start fitting things. I will

probably do the grinding outside so the dust does not settle in my garage. I

tried the engine in place and it looks tight but at least the gear lever seems

to be where it will fall to hand.

Plenty to keep me busy now.

Regards

Russ Collins

Rear view showing Panhard

rod behind axle

Engine

bay showing new bulkhead and reinforcing plates for subframe

Pair of UJs in steering

column

Subframe,

suspension and radiator in position

Phase 1 rear floor rebuild

I thought I might offer a few words regarding

progress (or lack of) on JEC 605s restoration. I have previously mentioned

the damage to the floor of the axle compartment as a consequence of excessive

downward axle travel, which had torn the floor over almost across half its

width. More detailed examination showed that other factors were also involved,

such as burning of resin by the exhaust pipe, numerous holes drilled to support

same and tobogganing on rough roads, some done by yours truly in an earlier

life. Also, the large cut-out in exhaust tunnel (by me on RMP instructions) to

give axle clearance had not helped.

I thought that if the floor tore across completely

the car might end up wobbling like a jelly, so this summer work was started to

replace fibreglass in this area. The axle could not be removed indoors because

of limited width, so the car was wheeled outside to do the work. To provide

good access the rear of the car was supported on blocks below the doughnuts

forward of the radius rods, before the mould construction was commenced.

The plan was to make a mould of the underside and exhaust

recess using a sheet of hardboard as the main lay-up surface, supported from

below by a solid piece of 18mm chipboard where the floor is flat. This

assembly would be located by four bolts drilled into the undamaged part of the

floor front and rear, and by others, to ensure that the mould was held tight

against the original body panel. Where the floor curves upwards, the hardboard

would follow this curve and the diverging gap between this and the chipboard

would be filled with expanding foam for support. In order to form the shape of

the exhaust recess, this space, now enclosed by the hardboard, would also be

filled with expanding foam.

Before doing this, the damaged pieces of floor were

straightened out, gaps covered with adhesive tape and a waxy parting agent

applied. Also, I decided on a slight complication to extend the flat area of

floor as far as the axle, so as to provide an extra 6mm or so of clearance for

axle travel. In hindsight I should have been much more meticulous with these preparations,

as I had some difficulty in removing the mould due to keying at the irregular

damaged areas. This caused some further damage to the mould surface, which

then needed repairing. In turn, this meant that I lost the exact shape at the

junction with the good part of the floor, and even more fiddling was needed

to make it fit.

With the mould removed, the damaged floor was cut

away as necessary in an irregular shape, and the edges feathered sharp with the

angle grinder over a 50mm strip not a nice job in that space! Incidentally,

there was no discernable loss of rigidity after the floor was cut out, though

no doubt the body strength would be much reduced, and it would have shown up

had I been able to apply a large enough force.

The mould was then trimmed, filled and smoothed where

the damaged floor had produced anomalies, and the exhaust recess was modified

by introducing a bulge to allow for full axle travel. A slot will have to be

cut in the bulge to allow the exhaust pipe to pass by, but this is a much

smaller cut than the original slot needed to clear the axle. Needless to say

the axle will contact the exhaust at extreme rebound, as before, but hopefully

the exhaust will deflect on its rubber hangers without damage.

The trimmed mould was painted with release agent,

then refitted to the underbody and located with the previously drilled bolt

holes. Stainless nuts were used on the upper (ie inner side) as these would be

buried within the new fibreglass and remain there. Timber strips were fitted

at each side of the mould to allow laying in of a flange, which would be folded

over a piece of oval PVC conduit to form a shallow box section. I always

thought that the original plain flanges were very little use, and they seemed

to split easily at the first minor impact.

I was quite nervous at tackling the glassing

operation, not having tried anything on this scale before, and realising that

if it all went wrong I would have to start again at the beginning. Also, with

the car outside, and autumn weather approaching, curing temperature looked like

being an issue. By enclosing the wheel apertures using polythene and tape, I

found that a redundant hair drier placed within the compartment would give me

up to 12C temperature rise, which proved to be ample for the prevailing

weather.

Materials were obtained from CFS Fibreglass in Cornwall,

who have a very informative website and a prompt despatch service. The glass

mat layers were cut out beforehand according to a plan, with staggered edges

and joins to allow for a smooth transition at the feathered edges of the

original floor. I did some trial mixes of the resin, and found that gelling

times were rather quicker than expected, even at quite cool temperatures (about

12C), so the catalyst proportions were reduced accordingly.

Between three and six layers of glass (of 300g/m2) were

laid down over a gel coat, starting at the innermost point, with resin applied

to each layer, several mixes of resin were needed, as despite every conceivable

preparation and cool temperatures, the gelling times were never long enough.

So don't mix too much. The centre differential hole was glassed over, to be

cut out later - no flange was included, as the axle depth does not permit at

this point. The final task of moulding the mini box-sections at the wheel

cutouts was messy, as the plastic oval conduit would not stay in place, once

more the consequence of insufficient attention to preparation.

Finally, the mould was removed, with difficulty, which

ultimately involved its complete destruction. Maybe more release agent would

have helped, as some of the mould surfaces after repair and smoothing were more

absorbent than others. Next time I will be really, really meticulous in my preparation

promise!

Apart from the difficulties of working in the confined

space, I was quite surprised at the ease of application of the mat, which

absorbed the resin quickly and, once wetted, could then be manoeuvred into

quite complicated shapes. I was quite pleased with my final result, but I will

have to improve my technique considerably, if I ever need to work on external

finish surfaces.

Final advice for other novices - No matter how careful

you are, wear a hat and don't expect clothes to be fit for much else when you

have finished.

Tony Clough

Original floor

showing damaged areas

Construction of mould showing foam in place

Mould

removed, ready for trimming and smoothing

Damaged underside, ready

to cut away

Mould and damaged

underside removed

Mould

replaced after trimming and smoothing

New panel moulded in place

OLYMPIC REGISTRAR

Bristol

Classic Car Show, Shepton Mallet.

Once again the Club took a stand at this show and Alan Farrer

had done all of the pre-show planning. However, family commitments (well you

can't miss a 90th Birthday party can you, as they don't come around

too often) prevented his attendance on the set up day. So the trusty Subaru

was loaded up with all the necessary bits and pieces and off we went to Shepton

Mallet.

Alan had arranged for two Olympics to be on the stand, Fred

Blackmores phase 2 and Nigel Whitakers phase 1. However, a last minute panic

phone call indicated that Nigel had been struck down by the Prince of

Darkness (a.k.a. Mr Lucas) and the phase 1 was to be a non-arrival. By the

time I arrived Fred was already there with his immaculately finished phase 2.

Compared to places like the NEC, set up at the Bristol Show

is the proverbial piece of cake, with parking right by the doors to allow for

offloading etc. Nigel arrived by modern Fiat and assisted in the setup, which

was accomplished in record time. This allowed for early retirement to the

B&B and pub to commiserate with Nigel over his continuing Olympic problems!

Saturday dawned bright but frosty and once again the

temporary heating didn't seem to be working in our Hall. A committee meeting

had been arranged and as the only non-committee member present, Ben Bettell

volunteered to man the stand whilst we sorted out Club business. Thanks Ben,

sorry we were so long.

By late morning the aisles were full and the Club stand

received its fair share of interest. The extra space generated by only having

one car certainly allowed Freds car to be shown off to the best advantage,

with plenty of room for the general public to inspect it at close quarters

without risking damage to the paintwork.

Sunday was equally as busy and as a bonus there even seemed

to be a modicum of heating in the Hall. To round off the weekend Freds

Olympic was presented with a Highly Commended rosette by the Show sponsors

Footman James.

Many thanks to all the Club members who visited the stand

for a chat and to help out over the two days and of course a special thank you

to Fred for providing his Olympic.

See you all next year?

ROCHDALE MOTOR PANELS

It was with sadness that I heard just before Christmas of

the death of Harry Smith, co-founder of Rochdale Motor Panels. An obituary

notice appeared in the Rochdale Observer. This happened just too late to be

included in the last magazine.

Harry founded the company in 1948 with Frank Butterworth.

Initially, work consisted of general car repairs, although, as both were panel

beaters by trade they soon started production of one-off aluminium bodies for

the Special builders and Racers. These were time consuming and therefore

relatively expensive to produce and output was limited to what the two partners

and their one apprentice, Ken Armistead, could make.

In 1953 they heard of a new material, fibreglass, and

realised that, once a mould had been produced the body shells could be

laminated by relatively unskilled labour. Whilst they were not the first to

produce a fibreglass bodyshell, despite what their literature indicated, they

were certainly in at the start and quickly gained a reputation for a well-produced

and competitive product. Over the next six years these shells were to generate

the necessary income to develop the more advanced monocoque Olympic.

Of the two partners I believe that Harry was always the

more cautious and generally looked after the finances. Unfortunately, once the

moulds and remaining spares had been disposed of Harry never really maintained

an interest in the cars and always insisted that he would rather look forward

rather than back. It is sad to think that the last remaining direct link to

Rochdale Motor Panels has now disappeared.

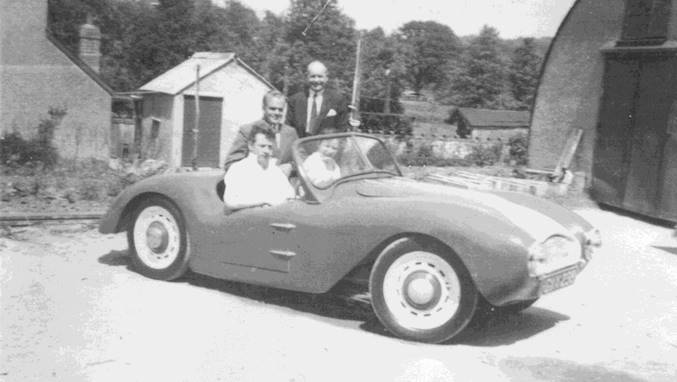

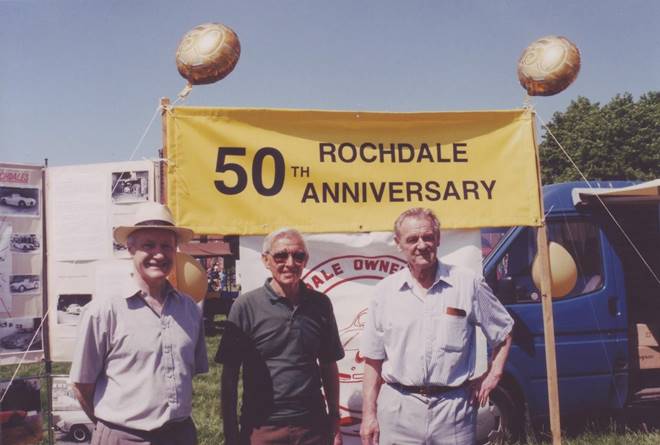

Richard Parker, Harry Smith and

Frank Butterworth at Capesthorne in 1998

OLYMPIC MATTERS

Over the Christmas period I have been spending time

updating records and gleaning Rochdale information from old motoring magazines.

The November 22nd 1963 edition of Autosport

contains a write up of the Trio Sprint meeting at Brands Hatch as

follows:

This left the struggle for the class

between B Appleton (Rochdale Olympic) and J D Green (Tornado

Talisman) Green was quicker by 0.4 sec.

first time out, with 2 mins 42.0 secs., but Appleton improved to

2 mins. 40.8 secs., which was more than

enough to redress the balance

According to the factory ledger Mr Appleton lived in Ewell,

Surrey and ordered a BRG Riley Olympic kit on 31st October 1961 (Ref

1673). This was delivered on 17th March 1962. However, I do not

have a registration number for this particular car to trace its subsequent

fate.

The 29th November 1963 issue of the same

publication contained a write up of Birmingham Young Conservatives MC Midland

Rally:

Provisional results from the 13 finishers

showed a win for H Whitehouse in his new Austin-Cooper, from the Rochdale

Olympic of W G Thornton.

Mr Thorntons name does not appear on my records, so

another unknown name and car.

Tony Stanton continues to assist with items of Rochdale

history which he is uncovering and passing onto me to update the club records.

Last year, Tony was told about a Phase 1 Olympic that had been built by Ashmore

Brothers of West Bromwich, who were the local Lotus agents. As if by

co-incidence a few days later I came across the following block advert by

Ashmore Brothers in the 5th January 1968 issue of Autosport

magazine:

For Sale: Rochdale Olympic.

Unregistered, unused, has not been on the road, fitted 1.5 Riley engine. For

the price this is an absolute bargain. An enthusiasts car with good economy.

Needs only to be seen.

£615. Ashmore Bros. Roebuck

Lane, West Bromwich. Tel: West Bromwich 2350/3103

1968

is extremely late for a phase 1, so we must assume that the car was purchased

much earlier, but for some reason took some time to assemble. Who purchased

the car? If it was sold locally it would have a West Bromwich registration or,

at the very least a very late registration number for a phase 1.

Looking through the records I have PEA 758F listed

as a phase 1, which is a West Bromwich number. The last recorded owner I have

for this particular Olympic is Mick Wright, from the Bristol area who

unfortunately passed away some years ago. Could this be the same car?

The co-incidences continue as at the Bristol Show Roger

Drinkwater was approached by someone with the immortal words a friend of mine

has an Olympic and it's for sale.

Roger phoned said friend, a Rob Garrett, who it seems has

owned PEA 758F for about 15 years! So at the very least another Olympic

has resurfaced and possibly another piece added to the jigsaw puzzle. I look

forward to hearing more in due course.

I recently spent a couple of lunch hours on a website which

gives a history of Harry Ratcliffe and British Vita Racing. (www.mountgreen.co.uk). When Harry left AVRO Aircraft he set up a tuning firm in

the Rochdale area with Jeff Goodliffe and started racing a Morris Minor. At

the end of the 1961 season it was decided to incorporate the best bits of the

Minor into an Olympic shell and one was obtained from RMP on 5th

September 1961.

Previous rumours have indicated that this was a lightweight

shell which fell apart during road testing. This would now appear to be

incorrect. The factory ledger gives no indication that this was a lightweight

shell and the website states that an errant lorry was responsible for the

shells demise. Harry had ordered a lightweight shell in October, but this does

not appear to have been taken up.

The website also gives details of Team Red Rose, which

contains some well-known names in Rochdale circles. As well as Harry Ratcliffe

there was Alan Staniforth, who of course had previously built a Buckler with a

Mark 6 body (SUG 55) and also a GT (VWR 555).

There was also a Neville Hodkin who had ordered a

lightweight Olympic in June 1961. This was registered 8500 DT and is

pictured in period publications being hill climbed at Olivers Mount and other locations.

It would appear that he later went on to race a Mini under the Red Rose

banner. I feel there is more history to come from this and perhaps even

contact with Neville to find out more about his Olympic.

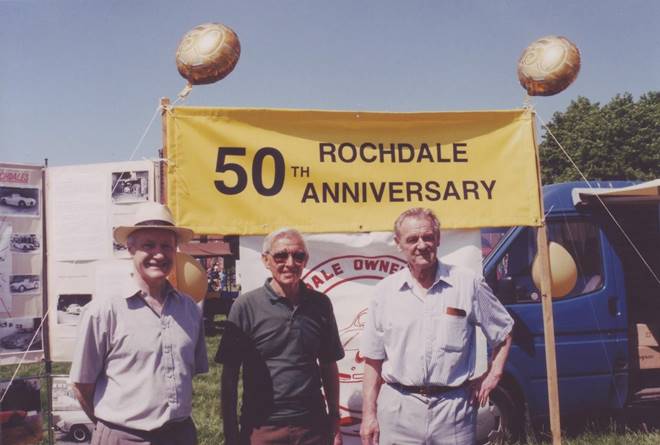

Neville

Hodkins Olympic at Olivers Mount in 1961

PRE-OLYMPIC MATTERS

As mentioned, over the Christmas period I have been

spending time gleaning Rochdale information from old motoring magazines.

The February 1958 edition of Motor Sport featured a block

advert by Chiltern Cars of Leighton Buzzard which reads:

GRAN TURISMO FORD 10 special

coupe with pretty fibreglass body by Rochdale Motor Panels. Low weight,

aerodynamically efficient body and a mildly tuned engine combine to produce a

very economical little car with Gran Turismo appearance and performance. £425

It certainly looks quite smart in the photograph.

What is very interesting is that of the sixteen cars advertised this is the

most expensive. There was the choice of two Aston Martins at £295 and £360.

Even an ex works pre-war MG Magnette was only £295. How times have changed

with old car values!

The June 1959 edition of the same publication contained

another interesting Rochdale advert, which reads:

Gran Turismo Cooper. Mark IV

chassis. Ford 100E engine, supercharged. Italian red Rochdale GT body. MG TC

gearbox. IFS, IRS, full instruments, carpets, lights. 0-60 mph in 10 secs. 112

mph. max. 30 mpg. Superb road holding with brakes to match. Shod Dunlop

R5s. Professionally constructed September 1958. Further details and full

history available. Out corners nearly everything. Complete with twin carb.

manifold, racing tyres, helmet (7) and spares. Bread and butter car in

exchange. £650. Radforth, 100, Allerton Road, Mossley Hill, Liverpool 18

Whilst the Cooper chassis may still exist I doubt that it

still wears its Rochdale body. I wonder if it was ever raced in its Rochdale

bodied guise?

Derek Bentley