MAGAZINE No 105 SPRING

2006

Bristol Classic Car Show Report

Our stand at the show this year show was organised

with the benefit of our experience last year and we asked for, and got, a

better position. This was not a lot warmer than last year, but a small heater

made things bearable and we were on one of the main through ways. As a result,

we had a very busy time, possibly one of the best ever, with a steady stream of

visitors to keep us occupied. I reckoned the time of year and the cold weather

ensured that only proper enthusiasts attended. Coupled with the informal

atmosphere and easy access this made for an enjoyable experience.

Derek Bentley had kindly volunteered to help with the

setting up and he and Roger and I had booked into the same B&B as last year

and had the usual welcome - very cosy - which softened the impact of doing a

show in the middle of winter.

We had space for two cars (just) and had the usual

Olympic, courtesy this time of Colin Ellis, and Roger Coupes Riviera. A small

Gazebo and a couple of display boards completed the stand. We also took the

opportunity to hold a committee meeting, thankfully in a heated part of the

venue the organisers office.

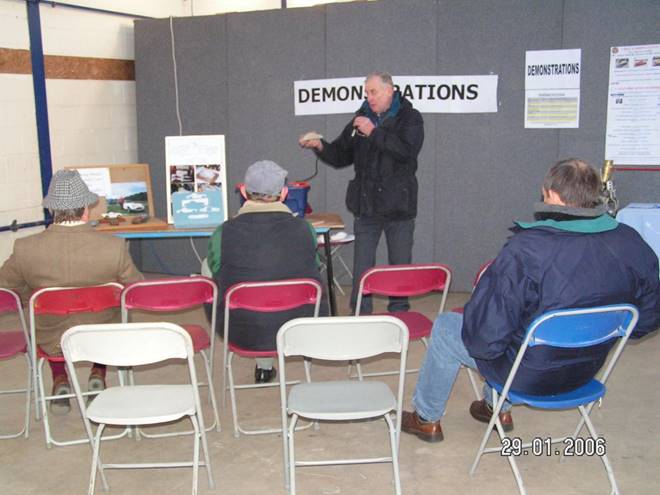

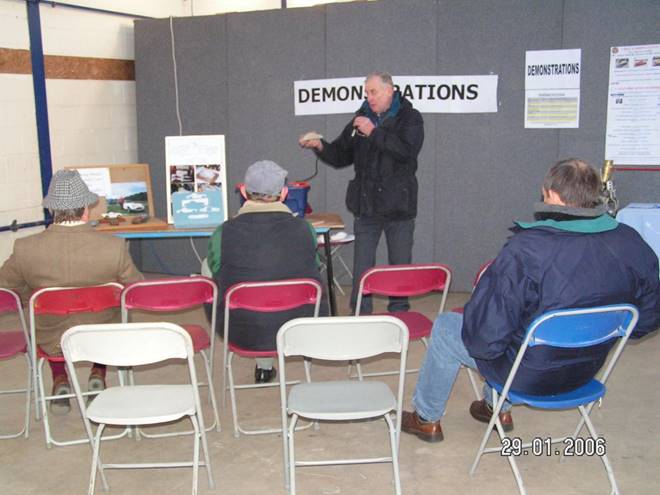

Roger had been volunteered to give one of the

talks/demonstrations by club exhibitors that went on each day. He showed how

he made his paperweights in the form of Rochdale cars and I for one found it

interesting and instructive. It was a pity that these demonstrations were not

better publicised, as they were poorly attended even Rogers!

Many thanks to Colin and Roger for the display cars,

and the other members who volunteered to help man the stand for cheerfully

enduring the chilly conditions. See you there next year? Hope so.

Alan Farrer

A quiet time on the stand

Roger

had one of the biggest audiences

EVENTS FOR YOUR

DIARY

AGM - 2 April (see page 1)

South Midlands

Monthly Classic Car/Bike Meet 12 March, 9 April, 9 May (see page

9)

Guy Stallards Spring

Start Up 23 April (see page 10)

Stoneleigh 06 Kit Car

Show - Sun 30 April/Mon 1 May (see page 9)

Prescott Hill Climb

Open Classic Car Event 2005 - 13/14 May (see page 11)

Cheshire Kit and

Classic Car Show & Rally at Capesthorne Hall 21 May (see page 4)

Classic LeMans - 7/9 July see website for

details www.lemansclassic.com/uk/ind

Royal International

air Tattoo, RAF Fairford, Glos - 15/16 July (see page 9)

Historic Specials Day at Burford - 13 August, organised

by the FSCC (date to be confirmed).

CAPESTHORNE WEEKEND 2006

Cheshire

Kit and Classic Car Show & Rally.

Sunday May 21st 2006 (10am to

4.30pm)

BE THERE!

We had a most enjoyable weekend last year, despite

slightly iffy weather, so we hope to see even more of you and particularly your

Rochdales this year, and that the weather will be good. The event is now open

to classic cars so, if your Rochdale isn't ready yet and you have a classic,

bring that along instead.

How can you help? We need helpers on Saturday

afternoon (20th) at about 2.00pm to erect our HQ tent, place various signs

around the estate roads, layout the public car park entrance, mark out the Kit

Car display area, mark out stall holders pitches, fix signs "to the

show" at strategic points around the approach roads, put out refuse bags

around the display areas etc.etc. I don't know if the sheep will be returning

this year but a trowel or shovel is a useful item to have with you just in case

- many hands make light work.

After the setting up has been completed circa 5.00pm

we shall be having a non-damaging driving test competition for the Rochdale

Motor Panels Trophy, this being competed for each year at Capesthorne with a

fun driving test competition in a Rochdale. For those of us who haven't got our

Rochdales on the road, last year was a great opportunity to re-familiarise

ourselves with the cars and demonstrate our judgement skills, thanks to the

generosity of those who allowed us to take part in their cars.

For the evening we shall be going to the same pub as

last year for a hot meal after which there will be a talk on a motoring topic.

For catering reasons we must know how many are going to be

present on the Saturday evening please let Roger Coupe (tel 01606 889384)

or myself (tel 01332 690680) know if you are coming and how many - otherwise

there is a risk there won't be a free meal for you!

On the Sunday your organisers and committee look

forward to seeing as many of you as possible together with your Rochdale or

Classic if you can bring it (unrestored cars on trailers are equally welcome!),

to ensure we all enjoy a companionable club day. If you have any ideas for

activities on the day or would like to help your club, please contact either of

the organisers before the day. It gives us much more confidence if we are

assured of a minimum number of helpers before the event.

On the day please report to the HQ tent when you

arrive so that we know you are around and perhaps we may even have a small task

for you! Remember this is your club and without the success of this event we

would find it almost impossible to carry on financially.

The reputation of this Show continues to grow and

grow, but we cannot maintain this reputation for the Show without YOU!

Finally, remember to bring this magazine with you to gain

free entry to the show.

Look forward to seeing you there,

Ron Scarfe (Show Co-ordinator)

(NB Capesthorne Hall is on the A34 about 16 miles

south of Manchester and 5 miles West of Macclesfield, and is 1mile south on the

western side of the A34 after the A537/A34 crossroads known as Monks Heath,

Capesthorne Hall caravan site 01625 861779 or in office hours 861221. Local

accommodation: Macclesfield T.I.O. 01625 504114 or Congleton T.I.O. 01260

271095).

Chair

Chat.

Well our Club has reached a milestone in its history.

This year marks the 25th anniversary of the

formation of The Rochdale Owners Club.

Back on the 7th of June in the summer of

1981 at a Limited Edition car gathering on the Melbourne Loop at Donnington

Park, a group of Rochdale enthusiasts put the wheels in motion to set up the

club as we know it today. I wonder if any of our present members can recognize

the cars in the photographs? It is interesting to note that the first club

magazine was published in the October of that year. So maybe we should do

something to recognize this milestone in our club's history. I think you might

find this as an agenda item at the forthcoming AGM. So please come prepared

with your ideas and suggestions.

Above and next page: Where it all started -

Donnington Park 7 June 1981

This year got off to a good start for the club with

the Bristol Classic Car Show. It was a very cold two days, but the company was

very convivial and there was a lot of interest from the public. Many thanks to

Alan for organizing the club stand, it's a date I will be fixing in my diary

for next year, that's for sure.

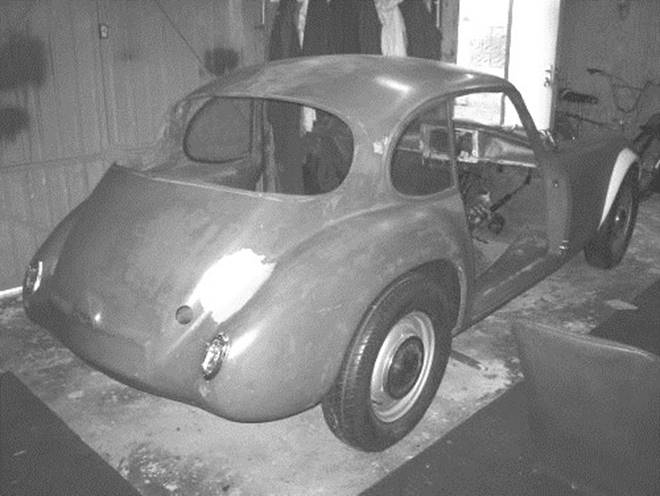

On the home front there has been a little progress on

"Sows Ear", but not much to see at first glance. Most of the time

has been spent on widening the track to fill out the rather wide Mk 6 wheel

arches. This has been achieved at the front by widening the split axle hinge

points. That meant I had to remove the transverse leaf spring and fit coil

springs similar to the set up on the Halifax Chassis on my Riviera. My next

task is to prepare the drive unit. This will consist of a Ford 100E Engine

fitted with an Elva O.H.I.V. head and Shorrocks Supercharger. The gear train

will be a period Ford 3 speed box fitted with Buckler close ratio gears

and a 4.7 back axle.

Sows Ear front end widened and converted to

coil-overs

Coming back to club matters, the next date for our diary is

the AGM on the first Sunday in April (April 2). It is always good to see so many

members and their cars, even though the pre-Olympics are still very thin on the

ground.

Then on May 20/21 we have the Cheshire Kit and

Classic Car Show. As ever the Saturday is developing into a great opportunity

for club members to get together in the afternoon to set up the show field and

take part in a driving test. This gives members a chance to have a drive in

different cars. Then in the evening we will once again be going to a local

restaurant for a meal and a chat.

I think you will find more details of both the above

events elsewhere in this mag. so I look forward to seeing

you then.

Roger.

**************************

Spares Note

Club member Derek Farrow has had some grilles made to

cover the air intake at the base of the windscreen. They are made in chrome

plated brass and are pictured below. If you are interested, please contact me

with a view to getting a batch made. Prices will be £15 for the slotted design

and £20 for the Rochdale one.

Nigel

Nigel

Olympic Phase II subframes

There has been a lot of discussion recently about Phase II

subrframes, as quite a few of them are reaching the end of their useful life,

and it has been very strongly suggested that the club should be manufacturing

replacements. At the recent committee meeting, there was a discussion covering

the main points, summarised below:

The originals frequently have different angles of camber and/or

castor on each side. This was hopefully a fault of inaccurate construction

rather than the original design.

Richard Parker is on record as saying that if he was doing it

again, he would design out the antidive by making the wishbones parallel

The original design used tubular steel of dubious quality

should a better quality be used for the tubes?

The

original design used spacers as a cheap method of both widening the track and

allowing a change of pcd. This is unsound engineering. Alloy hubs are now available

in any pcd required. However, have any cars experienced problems as a result

of using spacers?

On

the inner ends of the wishbones, the Rochdales have 1/2" diameter threaded rod,

whereas the original Triumphs used 3/8" bolts supported at each end. This

means that the Rochdales experience greater wear on the bushes as there is no

inner steel sleeve.

There is no facility for camber adjustment on the Rochdale.

If

the club manufactures a subframe of any type, but in particular if it is

significantly different to the original, where will we stand legally on product

insurance? Will we need to get the design tested by an independent qualified

engineer?

Some members, notably Colin Breakspear and Ron Collins and Peter

Bissett have produced subframes which have parallel wishbones, and use the

Triumph uprights. These seem to work well.

The original subframe jig has completely disappeared.

There had been very little (ie 1) response to the Editors plea

for input from the membership, although it was felt that if they were

available, more interest would probably be forthcoming.

It was therefore felt, as a first stage, that we should

measure as many original subframes as possible.

Derek Bentley has volunteered to produce a CAD

drawing of the subframe from these measurements. Once we had the relevant

dimensions, then we could decide whether to produce drawings for members to

use, or make the subframes as a club spare, and if this option was chosen,

decide what specification to use.

What do you think? Please let us know; come to the AGM and

make your views known.

Alaric

TONY STANTONS

EVENTS PAGE

The Royal

International Air Tattoo, RAF Fairford, Gloucestershire 15 & 16 July

The Royal International Air Tattoo is Europe's premier

air show featuring static and aerial displays of classic and modern, military

and civilian aircraft. This year's theme reflects the ability of the Armed

Forces to react quickly and decisively to events around the globe with the

theme of "Speed" taking centre stage. More details about the

Air Tattoo can be found online at http://www.airtattoo.com

This year, for the first time, we are including a

Vehicle Display dedicated to interesting vintage, classic and modern vehicles

of all types. This will be on one of the hard-standings normally used to park

aircraft. There will also be an exclusive area nearby for the use of anyone

displaying a vehicle.

We are pleased to offer a free pass to the Air Tattoo worth

up to £35.00 to anyone displaying a vehicle for one day or two free passes,

allowing a passenger to attend free, if the vehicle is displayed on both days.

Additional passes may be purchased at the normal rate of up to £35.00 (This is

the "on-the-gate rate", the sooner you buy them the cheaper they

are).

There are a few minor restrictions:

For health and safety reasons vehicles being

displayed must be in the display area from 7:30am until 7:30pm on each day.

Pre-registration is required along with details of the

vehicle, registered keeper, driver and any passengers. Passes will be

non-transferable. Passes issued will only be valid when accompanied by the

vehicle.

If you would like to display one or more of your

interesting vehicles please contact:

Tony Stanton e-mail tony-stanton@fsmail.net

STONELEIGH 06 KIT CAR

SHOW 30 April & 1 May

The worlds number one show for every kit car enthusiast

with old or new kit cars.

Tony Stanton has reserved stand No 39D with

which he intends to promote cars built before 1973. The stand is entitled:

HISTORIC SPECIALS AND

CLASSIC KIT CARS

Entry: Free for kit/classic car and driver Half

price for passenger

Entrance is via the main vehicular entrance (follow

yellow signs for clubs) which is located on the B4113 Coventry to Leamington

Spa road.

For more details contact Tony Stanton (as above)

South Midlands

Monthly Classic Car/Bike Meet

The second week of every month at Britannic assurance Plc, 1

Wythall Green Way, off Middle Lane, Wythall , Birmingham B47 6WG (on A435 1

mile north from M42 J3). Sunday 12 March, Sunday 9 April, Tuesday 9 May,

Tuesday 13 June

Social Club will be open for drinks. BBQ (weather

permitting) on the lawns. Wildlife park to walk round. Room for up to 1000

cars.

For more details contact Tony Stanton (as above).

Letter from Tony Wright Phase 1 779 CUG

Two things firstly I enclose details of the

Cheltenham & Cleeve Vale Rotary Club Classic Hill Climb event on 13/14

May. There is plenty to see in a fantastic historic venue with the chance of a

run at the legendary hill. It would be great to see Rochdales there; could you

mention it in the next magazine? OK

The second item involves me in an almost dreamlike

situation. Circumstance took me to a pretty cottage at the end of a small lane

on the outskirts of Coleford in the Forest of Dean. In front of the cottage

was a grassy paddock littered with one or two semi-redundant cars and, delight

of delights, three amorphous tarpaulin shapes. I called at the house but,

finding no-one in allowed my curiosity to take over. The first was so

unremarkable I forget what it was; the second an intriguing strange boxy shape

that proved to be a Midget. The third had an intriguing outline that defied

easy recognition but hinted at exotic compact, low, coupe. Could it be an

Alfa SZ, Renault Alpine or something even rarer? With trembling fingers I

lifted the brittle tarpaulin - the exotic blurring with erotic and their

delights - I recognised the familiar profile of an Olympic door and frame. Of

all the gin joints in all the world to paraphrase Rick.

I now reminded myself that with no owner present I

was trespassing, so just committed a few basic details to memory. These

included some body glass out, a mid-blue colour, one of my favourites - wire

wheels, a BMC lump which suggested Marina and finally no rear door which hinted

at Phase 1, but not conclusive. Finally, remembering Derek Bentley, I looked

for a registration number but could find none. I replaced the tarpaulin and

left a note at the cottage.

Subsequent contact with the owner Peter Thomas and

his wife confirmed the Phase 1 was originally registered JAC which has been

reallocated. It is for sale and Peter is on 01594 833943. During Peters

ownership it was repainted supposedly by professionals in a special boat finish

for fibreglass, but he was disappointed with the result. The car is complete

with original Riley rear axle and possibly MGB gearbox. Its condition is

compatible with standing on grass under a tarpaulin and requires energy and

persistence to return it to respectable road-going condition.

However I know we are among like-minded souls and who

would not see these issues overcoming the privilege of owning an enigmatic and

unique piece of sports car history - £650 to you squire!!

PRESCOTT HILL CLIMB OPEN CLASSIC CAR EVENT

Cheltenham Cleeve Vale Rotary Club invites classic car

owners to an event to be held on the weekend of 13th and 14th

May 2006. The event is open to all pre-1980 vehicles but exceptions may be

made at the discretion of the organisers for particularly interesting

vehicles .

Sunday 14th will be devoted to display and driving

the famous hill, with passengers if you wish, in marshalled but untimed runs.

Un-timed runs eliminate the need for crash helmets and the full gamut of safety

equipment etc. However vehicles must have valid road tax, MOT and insurance

documentation. The entry fee will be £20 per car and parking will be in the

Paddock

This year we will be developing a static display in a

designated area of the Orchard for classic, vintage and special

vehicles. We are also proposing to hold gentle cavalcade parades up the hill

so that they can be displayed in motion to the attending public. We feel this

will greatly enhance the presentation of the superb range of vehicles

expected.

Static entrants have a reduced entry fee of £10 which will

include a cavalcade parade.

On Saturday we are offering a 50 mile Cotswold tour starting

and finishing at Prescott, and in addition there will be a dinner/buffet at

Prescott Lodge. Both events will be subject to a minimum participation number

and are open to all entrants.

Block bookings by Clubs will be particularly welcome and we

will endeavour to park such groups together on Sunday. Spectators will be

welcome at £10 per car with free car parking and pedestrian access to the

Paddock etc. All profits will go to Charities supported by Rotary. In order to

maximise this we are asking for your cooperation to treat the entry fee as a

donation to charity under gift aid so that we can reclaim tax.

Following the press report of the 2005 event in Practical

Classics we suggest that to avoid disappointment, early booking is made on the

entry form*.

Organisers: Bob Price 01242 232527 & Geoff Kimber 01242

602643

* Contact me if you want a copy of

the entry form, or contact one of the organisers directly - Ed

A Subframe Saga

Anyone owning a Phase 2 Olympic will know about

rusting subframes and the associated repair problems (not only Phase 2 Russ!

Ed). My Phase 2 is no exception. It was built in 1973 and I believe had

been off the road since 1980. I acquired the vehicle from Tony Stanton in 2001

and was eager to restore it and get it back on the road. The strip down was

hard work but went without problems. I knew that the subframe was not

serviceable and managed to remove it for repair with the help of a Dremel and a

mini angle grinder that I purchased for the task.

The subframe was in a worse state than I had first

thought. Much of the lower portion had rusted almost to dust where it had been

glassed in. My first decision was to repair it to original, rust treat it and

glass it back where it came from. Talking to various people around the club

made me realise that certain things would be better changed before refitting

it. One of the changes that I decided to make was to dispense with the hub

spacers. This meant that the wishbone mountings would need to be further

apart. I cut the frame in two thinking that it would be a simple job to weld

in repair sections of tube.

Because the frame was now in pieces with some of the

lower half missing I made a jig to position everything correctly. A local

machine shop made lower wishbone mounts for me and I put these in the jig along

with the salvageable bits of the frame. Doubting my welding skills I entrusted

the repair to the welding instructor at the college where I worked. I provided

drawings and photos to help with the task. Months passed without progress and

he told me that he was having trouble sourcing the materials. I retrieved the

jig and bits and decided to think again.

It was now a case of giving the work to a specialist,

but who? It needed to be someone close by or else I would have to trailer the

body shell to someone like Keith Hamer. The project sat for some time while I

pondered what to do. Retirement came for me with its associated tightening of

the belt and I even thought of selling the car.

Fortunately I managed to get a part time job back

with the college and they had a new welding instructor. I did not want to go

through the same cycle as before with him but he encouraged me to invest in a

TIG welder and have a go myself. I purchased a second hand TIG welder but it

blew all the fuses in the house. I discovered that it was only suitable for an

industrial power supply and changed it (adding significantly to my bill of

course) for a more modern inverter unit. That worked well and I started

practising on bits of scrap. When I felt competent enough I went out to source

material for the job. The problem I found was that steel stock holders were

not prepared to supply the small quantity that I needed. I resorted to scouring

the area for steel fabricators using the sort of tubing I needed. I could not

find any using round section tubing so decided to build the subframe out of

square section which was available. (I must be lucky as there is a metal

stockist near me who holds lots of round and square ERW tube and sheet and

plate and is happy to sell small quantities - Ed)

After several materials forays I had a small stock of

mild steel plate (3mm and 1,5mm) and two lengths of square section tube (20mm

and 26mm). I was unsure of the strength of the tubing I had acquired, or of my

welds, so decided to make extensive use of gussets in the frame. I made a

start by joining upper and lower wishbone mounts using 20mm square tubing. I

next joined left and right suspension mounts using 26mm square tubing. Because

my jig was made of wood I tack welded bits in place then removed them from the

jig for the finished weld. I fabricated the spring/shock upper mountings from

1.5mm plate and welded these in place. I now had all of the front suspension

mountings in the correct relative positions but needing structure.

At this point I made another change of plan. There

has been a lot of talk about bolting the subframe to the body shell rather than

glassing it in. This has certain merits but would need some large plates

incorporated in the design to spread the load. If I made the subframe out of

plate I would not have to add anything to bolt to the body shell. I also felt

more confident in welding a strong structure this way.

The subframe has to fit the shape of the body shell

which is quite complicated so I spent a lot of time making cardboard patterns

and doing mock ups to get things right. I made two more jigs to sit on the

garage floor and hold the subframe in the correct position. The subframe is

now finished and looks rather like the original design plated over. The next,

and very tricky, job is to fasten it to the body shell.

My plan of action is to grind the body sections

reasonably flat where the subframe is to be fixed then cut the body shell to

form two flaps from the front part of the engine bay. I have allowed about

10mm clearance between the frame and the bodyshell, the idea being to position

the subframe correctly using my jigs then move the loosened bits of bodyshell

forward and bolt to the frame. After this I plan to layer up the front of the

engine bay to secure and strengthen everything. If all works well I should

finish up with a bolted in subframe giving the suspension geometry as designed.

I hope to have the wheels on the body by the summer

so that I can roll it out of the garage and make some more dust preparing for

general glass fibre repairs as needed. The shell is not too bad but there is a

lot of patching up required.

Russ Collins

18 Feb 2006

The jig with partially completed subframe Photos:

Russ Collins

The

completed subframe resting in its jig (The chalk circle marks the

position of the hole for the steering column)

Lifespan of the Olympic Body/Chassis Unit

I have started yet another rebuild of my Phase 1 and would

value members experiences with the bonded-in steel structures even if this was

gained through scrapping an Olympic. The drawing shows the items of interest

as they relate to the Phase 1 Olympic body/chassis unit (front suspension and

steering mounting points omitted for clarity).

Many years ago I took the car off the road to repair the

bottom section of the sub-frame that had all but disappeared. I now suspect

the other tubing bonded into the GRP of the engine compartment although

applying a magnet to these areas (A) indicates that some metal/oxide

remains. Prior to repairing the sub-frame the car had been on (and off!) the

road for fifteen years, eight of these in my possession. The corrosion was

worst on the side where the battery had been sited, the weight of which had

also caused some localised creep of undershield.

In addition to the above, there are the tubes (B)

that reinforce the roof over the windscreen and doors together with the

windscreen pillars. On my car the 1" tubing is exposed over the pillar

sections and shows some rust. Also, is the tubing over the windscreen

continuous or split (C)? I know from a previous issue of the club

magazine that the Phase 2 tubular reinforcement is in two parts, presumably to

facilitate bonding into the body whilst in the mould.

Other areas of concern are the rear turrets for the

mounting of the coil-spring/damper units. There is a steel bar (D)

bonded into the GRP at the level of each platform that puzzles me. Does any

member know what purpose they serve, is it structural or was it an aid to

laminating the platforms? Both these bars are heavily corroded from exposure

in the wheel arches.

Water vapour/humidity will penetrate to the tubing over the

years through porous sections of GRP and along the interface between GRP and

tubing where bonding is poor (there is evidence of this at the windscreen

pillars on my car). If the tube ends are not sealed adequately then the internal

surface of the tubing will also be exposed to corrosion although this can be

countered by timely spaying with WAXOYL or similar, if accessible. All this of

course assumes that properly cured GRP is impermeable to water vapour at the

thicknesses of laminate considered here. It is unfortunate from a preservation

standpoint that a chemically resistant structure should have been reinforced

with a material (mild steel) that was not, but a long lifespan may never have

been the objective. I am aware that members have replaced the complete

sub-frame with their own designs and there is a plan to offer a standardised

item as a club spare for the Phase 2. Should future re-manufacture of the Phase

1 body/chassis unit ever be considered necessary then corrosion resistant metal

tubing would need to be used. In the case of the sub-frame this could also be

bolted to reinforced sides of the engine bay as an alternative method of

location to bonding into the GRP.

Before I consider my next move, which could involve the

drastic surgery that I would much rather avoid, any information on the above

would be much appreciated.

Malcolm

Lomax Phase 1 Olympic 20 February 2006

LAMINAR FLOW

By Neil Roshier

Copyright: Race Performance and Car Constructor Magazine in

Australia.

The air that we breathe is a fluid. A strange thought as

we breathe it every day and every day we think of it as a gas! This is because

a fluid does not have to be a liquid, yet liquids are fluids. confused

yet? Stay with me and we will try and make this understandable and relevant!

An excellent description of a fluid is a fluid can be

defined as: having particles that easily move and change their relative

position without a separation of the mass and that also easily yield to

pressure and are capable of flowing. So basically, for the purposes of this

article if it can flow it is a liquid and we are very interested in flow for

engines it is generally the more the better!

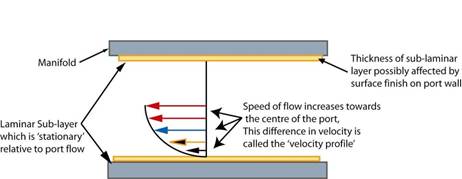

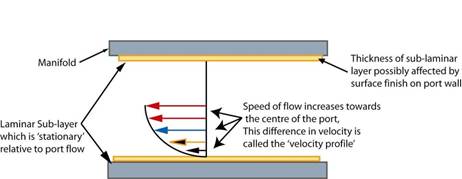

The trouble is, when we read articles about flows we often

read about Laminar flow. This is where the flow is nice and stable and meets

certain conditions (more on this later) and laminar flow is most often

described as being layered (these are the laminas per se). With respect to

intake ports this means that layer closest to the port wall is stationary (the

sub-laminar layer). The next layer is moving quite slowly due to friction with

the sub laminar layer and the next slightly faster again and the next one the

same again etc.

The trouble is, when we read articles about flows we often

read about Laminar flow. This is where the flow is nice and stable and meets

certain conditions (more on this later) and laminar flow is most often

described as being layered (these are the laminas per se). With respect to

intake ports this means that layer closest to the port wall is stationary (the

sub-laminar layer). The next layer is moving quite slowly due to friction with

the sub laminar layer and the next slightly faster again and the next one the

same again etc.

Eventually we have the layers that are moving as fast

as they can (see image ►) It can be thought of as a series of concentric

layers, a bit like a telescopic radio aerial. The outer most layer is the sub

laminar layer and the inner most part the fastest flow with the other bits

between being the other layers.

Why Laminar flow is desirable is simply down to the fact

that it is faster, more stable and less likely to break away from the port

walls when encountering a change in direction (such as a short turn radii prior

to a valve) or imperfection (manifold/head joint). All of which means that more

air (though this aspect changes if we are using Carburettors as it will not be

just air due to the fuel in suspension) will flow through the same diameter

port at a given airspeed. For us with an engine this seems very attractive as

it will mean the engine will make more power, given all other factors being

equal.

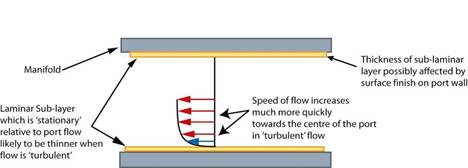

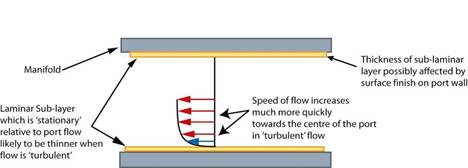

But what we must also

acknowledge is that this is a nice neat explanation of laminar port flow is

often misleading or worse factually incorrect! What we find in an intake port

is that the laminar flow as described above has always been turbulent flow.

This means that the velocity profile will be considerably different to what we

might expect of a laminar flow (see image ►).

But what we must also

acknowledge is that this is a nice neat explanation of laminar port flow is

often misleading or worse factually incorrect! What we find in an intake port

is that the laminar flow as described above has always been turbulent flow.

This means that the velocity profile will be considerably different to what we

might expect of a laminar flow (see image ►).

This change from Laminar to Turbulent occurs when the

diameter of the port, the fluid velocity and the viscosity of the fluid

(remember the bit about carburetion and fuel in suspension) creates Reynolds

numbers higher than 4000.

So now you are probably asking yourself what is a Reynolds

number?

The Reynolds number is the dimensionless combination of

variables that is important in the study of viscous flows. The Reynolds Number

is important in analyzing any type of flow when there is substantial velocity

gradient such as occurs in the intake port as described above. The Reynolds

Number indicates the relative significance of the viscous effect compared to

the inertia effect. The Reynolds number is proportional to inertial force

divided by viscous force. Reynolds Number can be expressed as:

Re = D.V.ρμ

Where:

D = Characteristic length (port diameter) μ =

Viscosity ρ = Density V = Velocity

So if we consider that some definite numbers are: The

intake port is 31mm

The viscosity of air (absolute) is often given to be

.000017894kg/m/sec (at sea level).

Density of air is often given to be 1.225kg/m3 (at sea level and

given temperature)

So what is then missing to work out the above equation is

the velocity of the intake charge. Here we come across another decision: do we

use the average velocity or do we pick the peak velocity?

However the average port flow is just that, an average. It

is made up from the lowest flow through the port (e.g. when the piston is

coming back up the bore and the intake valve is closing) to the highest flow

rate (when the intake valve is opening and the piston is accelerating down the

cylinder). Of course what we want is the most efficient intake system for the

designed purpose.

The basic measure is: laminar

if Re < 2300 transient if 2300 < Re < 4000 turbulent if 4000 <

Re

So now when we consider the flow in the intake port,

instead of having nice, stable concentric layers of flow that are relatively

discrete from each other (Laminar flow), we now have Turbulent flow. This

turbulent flow also has characteristics that are important for us to understand

as far as intake ports are concerned.

1.

Turbulent flow means energy transfer from one layer to another

due to the chaotic nature of the turbulent flow itself, either accelerating or

slowing the adjacent layer and increased surface friction.

2.

The sub laminar (layer in contact with port surface) layer is

thinner and less stable, thus it may be more adversely affected by local

conditions such as poor manifold gaps, surface irregularities and flow

separations due to too tight radii.

3.

The progression to V-max flow occurs quicker in turbulent flow

than for Laminar flow, though the V-max may be relatively lower (given the

increase in pressure drop) than for Laminar flow (it is not possible to

directly compare the overall flow of turbulent/laminar as they require

different/incompatible conditions to exist).

4.

Turbulent flow may be more disturbed by and may require greater

time/distance to recover from any disturbance, e.g. a throttle plate at 45

degrees. It was suggested to me by an engineer who works in the field of Fluid

Mechanics that often flows stabilize after a disturbance of 10 diameters (of

the port diameter). So if the port had a 22mm diameter then flow would be

stable and well formed again in 220mm.

5.

Turbulent flows may under some circumstances have beneficial

effects on fuel vaporization, though we cannot verify this from any independent

source, so don't believe it yet!

To be continued.

Minilites,

Minators and Minilights

Why are spares for some makes so much more expensive than

others? One way and another, I haven't had much to do with Vauxhalls through

my motoring career, and at £55 each quoted for hubcaps I wasn't about to change

that. Crikey, I'd just bought a set of stainless Minor items for the GT

for a fiver, so £220 to freshen up my Olympic wheels seemed a little excessive.

What were Vauxhall bits doing there in the first place? With a Riley axle and

Triumph-based front, they hardly seem the most obvious choice, but apparently

this is what many Olympics received around 1964. Couple the prices with the

fact that the Vauxhall wheels were looking decidedly skinny, and I decided to

look round for alternatives.

Classic style Minilites look good on most old cars and

similar styles have been offered by a number of manufacturers over the years. I

believe that the original Tec-Del firm had gone out of business sometime in the

70s/80s and other firms got round the copyright issue by marketing their own

wheels as Minilights (note the spelling) - the subject of legal proceedings at

one stage. Add in the re-forming of Tec-Del and similar products such as KN

Minator and you now have quite a buyers market in the UK. I was very

pleasantly surprised by some of the quotes, and eventually went for 5x13 Midget

wheels from Midland Wheel Services. In Anthracite (dark silver) and with a

polished alloy rim they looked the business, and at £200 including centre caps,

chrome nuts, VAT and postage I didn't take long to make up my mind. I figured

that with a 5" width they would fill the arches better than the originals and

was assured that with an ET20 offset they fitted a Midget easily I kept my

fingers crossed as the tyres were changed.

(ET20 means the mounting flange is

20mm outboard of the wheel centre line Ed)

No problems at the front they really improved things

but at the back clearance was much more limited, though I thought at first I

had just got away with it. Not so. It became apparent that the tyres were

rubbing as the suspension came up, and I tried grinding away at the returns on

the arches. Much of this didn't go amiss the job had clearly been very

crudely tackled when the shell was new, and I did manage to get clearance

just on the left hand side. On the right, however, the problem persisted with

the tyre (155/80 Michelins) scuffing the rear of the arch where the body

tapered inwards. Further grinding away at this point eventually broke through to

the outer surface of the body and I built up the contours with extra layers of

fibreglass. This still wasn't a good idea, however, as the tyre continued to

wear away on full bump, which seemed odd a close look at other Olympics

didn't reveal any problems, with lots of clearance. Now in the overall scheme

of things 5" isn't a very wide wheel, and it seems the problem lay in the ET 20

offset. I had never heard of this before I bought the wheels, but it apparently

represents a distance of 20mm from the mounting surface to the centre line of

the wheel and was the standard distance used by each of the manufacturers I

spoke to any more would be likely to foul on disc callipers, I was told.

There looked to be lots of clearance on the Olympic, however, and I did call

MWS again to discuss the possibility of shaving a little off the mounting

surface of my own wheels but surprise, surprise they didn't want anything

to do with it, and no, they didn't sell wheels with any other offsets. Hmm

Yes, I know it's possible to flare the arches but I really

didn't want to and neither did I want to cut them away as has sometimes been

done. Thoughts of subtle modifications to follow the original lines while

spacing them out a few mm were rejected because of the amount of work involved

and I eventually decided on replacement. Both Tec-Del and KN were more helpful

here, and I eventually took the plunge with a further set of Minators to

replace the originals - this time with an offset of ET30. The financial side

was a little less favourable this time, with a total bill, including postage of

around £256 for the four, including centre caps, postage and VAT but no nuts.

If 5" doesn't sound very wide, then a difference of 10mm

sounds even less significant, but was nevertheless enough to do the job. The

arches are now cleared even on full bump, and there is still lots of room on

the inside 1960s callipers are much less meaty than later items, it seems.

It was very difficult to see any difference between the original

MWS and new KNs without careful measurement, though it is apparent that the

wheel nuts are less heavily recessed on the KN items. I would advise anyone

thinking along the same lines to check any wheels very carefully before taking

the plunge I think even 5" width may be possible with more offset, the

problem being the distance measured in the opposite direction between the

brake drum and the surface of the tyre. This can be easily found using a

combination-type square as shown and laying the wheel, face down, on a flat

surface. The KNs + Michelins give a reading of almost exactly 2 much more

and you are asking for trouble. Of this, the tyres account for about 1/4,

giving 1 for the bare wheel. Sorry to mix the units up but hey, tyre manufacturers

have been doing it for years.

Using a

combination square on the back of the wheel to measure the protrusion of the

outside edge of the tyre from the mounting surface (brake drum). Any

more than the 2" seen here is pushing your luck. All photos by

Les Brown

Now for the silly bit. After observing a lull in E-bay

prices going up to Christmas I polished up the Minilights and took a nice set

of pictures before putting them for sale in January. This started something

akin to one of those Piranha-type feeding frenzies that you used to see in

James Bond films with 11 bids going in with quite a few above the original

price of the items! I eventually came away with £221, including postage (but

no wheel nuts) and I was left wondering why a) I hadn't done it months before

and b) folks don't check on brand new prices before they start bidding. But I'm

not complaining!

To summarise,

Riley axle + 5x13 + ET20 = BAD

and Riley

axle + 5x13 + ET30 = GOOD

The

back of the rear arches is the problem area - you may just see the wear on

the outside edge of the tyre. New Minator on the right.

Original

MWS Minilights on the right, replacement KN Minators on the left - hard to spot

any difference.

EARLY ROCHDALES

REGISTER

Malcolm McKay

Winter's always a quiet time and I warned Alan I didn't

have much to say this time but I'm glad to say that now I've put it all

together, there's still been plenty of action on the early Rochdales front!

Aussie update

First to respond to the publication of the Register in the

last issue was Gordon Cowley in Australia thanks, Gordon, for bringing us up

to date with your very fine modified GT. Gordon writes:

The registration number is to be GT 1172. The Chassis

number is ROC 1172. The people here who had to approve the import kept asking

for a chassis or VIN number, which in my case did not exist. I told them that,

but that was not good enough. I invented the chassis number and was then

allowed to import the Rochdale GT.

I have a modified Bowden Chassis with a 105E rear axle

held in with five links and coil-over shockers. The Bowden IFS has been removed

and replaced by a Ford Ten beam axle with Mk1 Cortina hubs and disc brakes. I

have a Datsun Sunny steering box and a Mazda 808 steering column. I used the

top backing plate bolts and the specially made caliper bracket to bolt a Mk1

Escort steering arm in place for the draglink to work with. The drag link sits

over the radius rod on the LHS. The tie rod sits under the radius rods in the

usual place.

I will be using the 100E long engine that I initially

used in my 1952 Anglia Tourer. The Tourer now has a worked Ford Ten engine.

Both the engines have a modified camshaft and an external oil pump. I will be

using a Willment OHIV head. I have a split braking system and no room to fit

the twin Solex 35PHH carbies that I bought, as the master cylinders are in the

engine bay. I will be using one of the carbies with a modified single DCOE

Weber Cortina 1500 inlet manifold.

I have a 100E gearbox complete with Laycock electric

overdrive and the Rochdale GT will run on 13in Mk1 Cortina wheels. I can only

use the o/drive with second and top gear. I have a reverse light switch as well

on the gearbox and will fit the reversing lights to go with that.

I have used a Mk1 Cortina fuel tank and the spare tyre

fits on top of that. They are both behind the rear axle. I have made up a

propeller shaft hump and a cover for the gearbox and remade the engine

bulkhead. I have used fibreglass sheet, plastic body filler and aluminium strip

and angles to hold it all together. I need another layer of glass over the

bottom, interior and engine bay before paint and final assembly.

I have a three-hole instrument binnacle from a Mk1 Cortina

GT and will use an original Mk1 Cortina tacho and fuel and temp cluster with a

modern electronic VDO speedo. I have a pulse driver on the gearbox and you

can change the number of pulses per kilometre to get the speedo correct for

speed and distance. I have no gearbox cable or gearbox drive ratios to worry

about. Suzuki vans and small four-wheel drives have good nylon-bushed bits to

make remote three-speed and reverse shifters. I have internal door hinges,

electric window lifts (easier to fit than a hand winder) and Mazda 808 door

locks and recessed door handles. The interior may just be paint!

I have gone back to work, Mon to Fri, 8 til 5, so it is

now hard to find the time to finish my project. I have always been a tinkerer

and improver of cars, so I have no qualms about making my Rochdale GT of the

time that I chose (1961) with the best period bits that I could lay my hands

on and up to date in as many other ways as possible.

Thanks for that, Gordon it sounds as if you'll have a

very pleasant and usefully lively GT after all that work!

Trimming a GT

Dave Milner puts us all to shame with the work he

manages to put in on his Rochdales, despite work and family demands. His

Rochdale-chassis GT, which languished for so long in Northern Ireland and came

so close to being broken on several occasions, is now coming together and Dave

has delighted me by finally settling on a 100E engine to power the car, as

original.

He asked on the club website forum recently whether

Rochdale ever offered the GT with interior trim; it's a question that deserves

wider airing. I knew that Rochdale never offered anything, but doublechecking

my records turned up one surprise. Interestingly, the major London distributors

Super Accessories offered a Headlining and Trimming Kit specifically for the

Rochdale GT for £13, saying

Having seen so many GT saloons spoilt by poor internal

finish, we have developed a complete trimming kit comprising: -

Ready to fit Headlining (should be fitted before bodyshell

is mounted)

Windscreen Pillar Trim

Door panels covered in leathercloth

Parcels shelf for rear

Adhesive

Screws and screwcups

Leathercloth for odd trimming

Colours: Grey headlining with Blue or Dove Grey

leathercloth

To the best of my knowledge I've never seen a GT with

this trim kit, though quite a few surviving GTs have had headlining neatly

installed in the past. I do have some nice photos of period-trimmed GTs, some

really impressive. Sadly, none of these GTs survive, as far as we know and

all are different. Most of the more ambitious trimmers of the time opted for a

full-width dashboard with the instruments ahead of the driver: there was room

for this on top of the moulded dash panel and glove pockets that came with the

shell. Cutting the dash panel out was a mistake that many subsequent owners

have made doing so weakens the shell and is definitely not advisable. At

least one of the cars pictured retained the moulded glove pockets behind a neat

full width wooden dash panel with hinged lids over the pockets.

As for seats, everything from cut-down Ford Pop to

contemporary bucket seats were used and most using Ford Pop chassis fitted seat

pans set into the chassis members to lower the floor and give more headroom.

In the photo of EBV 358, complete with lady driver,

it's just possible to make out the standard Rochdale dash layout with the

instruments in the centre and untrimmed glassfibre windscreen pillars. The car

has the flat floor with low, but wide, seats and as can be seen, headroom even

for the lady driver is minimal! Also visible is an old-type electric windscreen

wiper motor simply mounted through the dash in front of the steering wheel

effective, but not very pretty. These motors, as fitted to quite a few

1930s-50s cars, were operated by a switch on the casing, so needed to be

accessible. One modern item on this GT is separate flashing indicators, and

these appear to have a column switch, below the wiper motor.

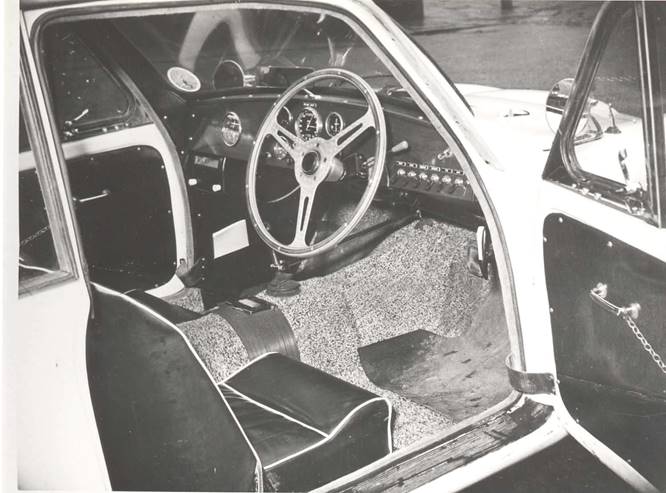

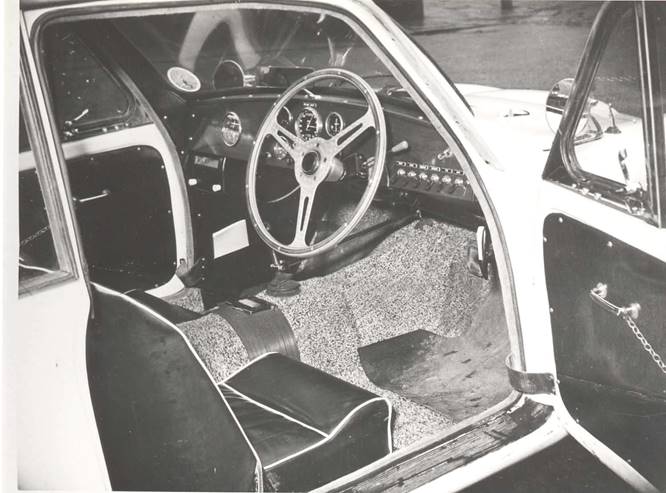

KS 101 which, like EBV 358, was photographed in

Rochdale and was a car well known to the factory goes to the opposite extreme

and I would be interested to know what chassis was under this car. It's

certainly not the Ford chassis, as the body flange just inboard of the doors

that bolts to the top of the chassis has been cut away and the car has neat,

flat floors two or three inches lower than the normal position, with a

commensurately higher transmission tunnel. Neat period accessory seats are used

and the interior is very neatly carpeted. Door, footwell side and screen side

panels appear to be glossy so are probably painted there is no rough

glassfibre visible anywhere and a full-width varnished wood dashboard is

fitted.

EVB

358 Note minimal headroom, even with lady driver

KS 101 - A highly specified

car

No expense has been spared on this car which has a

lovely wood and alloy steering wheel and a valve radio set over on the far

side. Sturdy leather door check straps are fitted, as are stainless steel door

window frames from the Morris 1000 Traveller and chrome interior door handles

with chains to the interior door handles. The Ford Pop umbrella handbrake is

neatly tucked in on the far right under the dash, where hopefully you won't

catch your knee on it when getting out (a common problem on early P4 Rovers).

There's a smart chromed remote gear linkage, a good set of centrally-mounted

instruments, a column switch for the indicators and a bank of minor switches to

the right of the steering column. There's even an ashtray set into the

transmission tunnel!

NBN 115 was another high-spec car, but not to the same extent

as KS 101. This one is on the Ford Pop chassis with standard floors and painted

door tops. Nice touches are the wacky bucket seats, chromed remote

gearchange, centrally-mounted handbrake, wood/alloy steering wheel and

comprehensive instrumentation in a dashboard that has been built out and bears

no resemblance to the standard offering. Flat rexine-covered door trims have

been fitted and it looks as if a white headlining has been fitted and brought

down the screen pillars to the top of the dashboard. Furflex door seals are

fitted, too.

HG 6688 is a very well thought out,

attractive and relatively inexpensive interpretation. It has a

late 103E steering wheel and its instruments which appear to include the Ford

speedo and fuel gauge with an ammeter and a dual oil/water gauge added are

mounted to a board set over the standard moulding and hooded, so that

illumination is provided from a bulb behind the curved hood. On either side

wood (or more likely Formica!) glove box lids are fitted, with a grab handle

for the passenger, very tidy carpeting with rubber heel mats and

colour-coordinated seats, door trims, footwell side trims and screen pillar

trims. A gutter has been fitted to the outside of the door opening as well as

Furflex door seals. Again, a remote control gear linkage is used, this time a

simpler painted one but neatly set off with a gaiter matching the trim. An

internal door handle is fitted with below it a trimmed door pull strap. The

Ford handbrake is used, but this time mounted low down to the left of the

footwell to avoid the knee risk. The only thing I haven't managed to identify

is the round black blob immediately above the internal door handle.

I hope these give some inspiration to everyone

contemplating how to trim a GT!

Lost GTs

resurface

I hadn't heard from HFJ 886 since it was rescued by

Chris Lane 10 years ago and handed over to his friend C Bent. I suspect it's

still in the same ownership, as it was spotted in the Forest of Dean last year

by Turner owner Nigel. At first glance, it appears little better than 10 years

ago, apart from the removal of the ugly pair of spotlamps that had been mounted

on top of the nose, but a closer look at the rear view shows shiny silver/red

wheel and hub that suggest the running gear may well have been nicely restored,

just (!) leaving the body and interior to do.

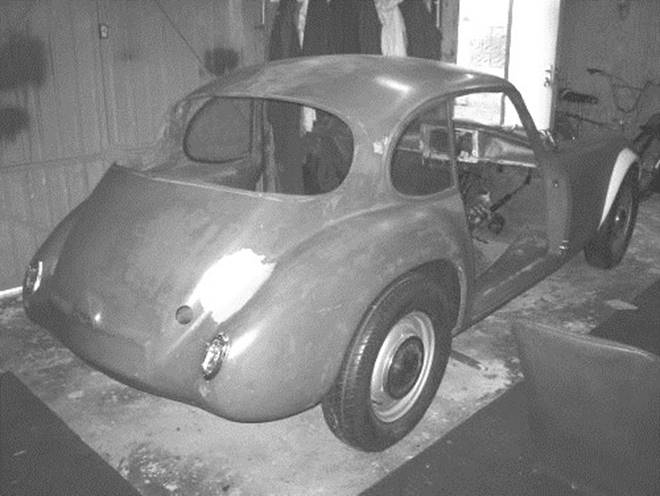

Also in the Forest of Dean (a great haven for

Specials!) is Granville Phillips GT, a very high spec car that, back in 1958,

featured in Rochdale Motor Panels adverts for the GT. Granville found the car

covered in snow lying in the corner of a field about 20 years ago and has since

restored it twice, having had several setbacks along the way. I don't have the

full spec sheet to hand for the car, but recall it had a Willment

inlet-over-exhaust cylinder head with twin SU carburettors, independent front

suspension, telescopic dampers and plenty more.

The car now runs and drives but still needs spraying

and a complete interior fitting out. It comes with lots of spares including a

wooden dashboard and, if the work has continued to the same high standard as I

saw when I visited Granville about 15 years ago, I'd say it's worth the £2000

he's asking. If you think that's a lot, bear in mind that the last Willment

head seen, an incomplete kit on sale at Beaulieu last September, was priced at

£1500. And I don't want to hear that this historic Rochdale has been robbed for

some jumped-up Lotus Six replica

If you're interested, give Granville a ring on 01989

768369 or 07917 152065 and do check that the Willment engine is still in the

car, as he didn't mention it when he rang to say he was selling. Without that,

sadly, it's probably not worth the asking price.

Worlds most

valuable GT

The GT that made a record price on ebay last year,

heading to Japan from USA, has rather surprisingly changed ownership within

Japan but I'm delighted to welcome new owner Hideki Saka of Hiroshima. As the

photograph shows, Hideki is a Lotus fan with a couple of fine Elans already in

his collection. Hideki is very keen to get the GT into 100% correct order and

has asked for help in reinstating the original number plate light plinth. At

some time in its history, which included being exported from UK to Holland in

the 1970s where it was restored and maintained in superb condition for decades

by Bert Tressel, the car lost its original rear number plate light and was

fitted with lights at each end of the plate.

This is not an

uncommon problem for GTs as, without bumpers, the number plate light is the

most prominent part at the rear of the car and any rear impact tends to push

the light and a section of glassfibre behind it into the boot. I suspect that, when

this car was restored in Holland, the plinth and light had been broken in such

a way and had disappeared, so the restorer glassed in the hole to match the

surrounding profile then wondered where to put number plate illumination

This is not an

uncommon problem for GTs as, without bumpers, the number plate light is the

most prominent part at the rear of the car and any rear impact tends to push

the light and a section of glassfibre behind it into the boot. I suspect that, when

this car was restored in Holland, the plinth and light had been broken in such

a way and had disappeared, so the restorer glassed in the hole to match the

surrounding profile then wondered where to put number plate illumination

Thankfully, Dave Milner has come to the rescue,

tidied up the plinth area of his GT and taken a splash moulding off it. He's

kindly promised me a moulding of the section too, as the same problem has

befallen my own GT at some time in the 35 years it's been off the road thanks,

Dave!

School Project

GT

Club member and Olympic driver Les Brown spends his

working hours teaching IT in a secondary school and deserves all our admiration

for investing a good deal of spare time into teaching the boys a bit of classic

car restoration, using a Rochdale GT as the subject!

Les and the boys have been making steady progress

over the last year or two and at last the project is really come together, with

the body gleaming in hand-brushed coach enamel. This GT is on a modified

Triumph Herald chassis, fitted (just to make life difficult?) with a Morris

Minor engine and looks likely to be a very fine car when finished well done

Les and all the team.

Les remarks:

"I've been concentrating on the GT lately, with

time running out to finish it before retirement. Seats are in, steering's

working, paint's mostly done (coach enamel - bright red) brakes are on,

carburettors next and I ain't looking forward to all those electrics. Kids keep

on about making Capesthorne but I have my doubts!"

Surely not, Les we're confident you'll make it! I

was terrified by electrics too before I bought my first GT. It had no wiring

loom in it, so I bought several big rolls of wire and a load of connectors from

my local accessory shop and set about wiring it up. It's quite simple really

when you do it that way, because you can deal with each item in turn, take a

wire from the light or whatever to the switch (and another to earth), then

power to the switch from the appropriate side of the fuse box, etc.

Try to route the wires together and, when they're all

done, bind them together neatly with black insulating tape or self-amalgamating

tape (see note below Ed). In an ideal world you'd use the

same colour-coding as other cars but on such a simple car you can get away with

just using three colours blue for lighting, red for live, black for earth

or if you've access to more colours, go for the standard pattern of

black-earth, brown-live, yellow-charging, blue-headlights,

white-ignitioncontrolled live wires. Taking a wiring loom out of another car

and stripping it for the exact correct colours is another option, but very

labour-intensive and fraught with problems such as damaged wires or ones that

are too short. Good luck, Les!

Note: I have done a lot of wiring

recently and wouldn't recommend either of these, Malcolm. It's better to use

the correct PVC harness tape, which can look really smart if done neatly. It

does not get sticky like insulating tape and is much easier to apply than

self-amalgamating tape, which needs real skill. Alternatively, use split

convoluted sleeving to cover bundles of wires, as applying tape of any sort is

a slow job. Braided sleeving gives a period look but needs planning. If you

use crimped connectors use a proper ratchet crimping tool (about £20) not the

Mickymouse sort usually offered. If you use bullet connectors for authenticity

always solder the ends rather than poking the wires in and hoping for a

miracle. Also, smear a little copper grease on the bullets before fitting to

combat corrosion. Heatshrink tubing is also very useful for covering soldered

joints etc. A heat gun is necessary for this; I have seen hair driers

suggested for this job though I wouldn't want to put my head under a hairdryer

that can shrink tubing!!!

All this stuff and lots more can

be obtained from www.autoelectricsupplies.co.uk, whose online shop is a doddle to

use. Usual disclaimer. Alan Farrer

The MM engine in Les Browns GT

FBHVC NEWS

DVLA

Sandy Hamilton

I had hoped that the April 2004 consultation on

inspection procedures was in the past but the September 2005 publication of

responses to it seems to have caused confusion amongst some enthusiasts and

certain of the specialist press. The following comments are intended to lay to

rest the fears and anxieties that some of the scare-mongering stories have

generated amongst those inclined to believe in conspiracy theories.

The original consultation was a ten-year review of

procedures first introduced in 1994 following earlier or consolidating

legislation. This had included establishment of Single Vehicle Approval (SVA)

testing for imported and amateur/kit-built vehicles. In essence, the

consultation wanted to establish whether the procedures had been effective,

were they working properly or did they need improvement and/or amendment. If

they were considered satisfactory that was OK, since there was no hidden agenda

to sneak yet more restrictions upon us.

Replies were to be submitted by July 2004 and,

following digestion of the 431 individual responses, DVLA published their

analysis in September 2005. It was at this point that some parties began to

huff and puff and to circulate stories that any modification (even changing

seats or brakes) would render a vehicle liable to an SVA test, removal of

historic status (if applicable) and re-registration with a 'Q' mark - or worse

- removal from the road.

Cutting through the hysteria it seems that those most

concerned had missed the introduction of the new procedures in 1994 or, if they

had been aware, had not fully understood the nature of the 2004 review

consultation. Their fears sprang from selectively reading the 'recommendations'

that were attached to each review category. These were in fact a summary of

respondents views expressed in their replies, and were not those necessarily

supported by DVLA. Indeed these recommendations were to be subject to further

analysis and review and only those that had merit, or could be cost-effectively

introduced, would be subject to formal proposals and further consultation.

Having spoken to the relevant departments at DVLA I

am assured that no recommendations are being acted upon that would give rise to

some of the wilder theories about extension of SVA testing, withdrawal of

registration marks, or restrictions on use, or the ability to undertake vehicle

modifications. DVLA has no desire to be informed when you have changed to alloy

wheels, added spotlights, new seats, disc brakes etc. The only changes that you

are obliged to inform are those that are annotated on Section 7 of the V5C

document and that affect identification (personal and vehicle) and have

potential VED revenue implications.

A caution is that unregistered vehicles built from a

variety of spare parts ('rebuilt classics') may need to obtain certification as

to the age of components and to obtain confirmation from a recognized club

prior to being allocated an appropriate age-related mark. In those cases a

radical departure from the original specification may require a DVLA inspection

to establish how much of the original design is retained. The principal

category potentially affected would appear to be extreme customisation where,

for example, 'chopping and channelling', changes to design of suspension and

steering so radically affect the appearance that the vehicle no longer

resembles the original outline or style. For avoidance of doubt the above is a

summary of existing requirements since 1994 and is not new. Very if any few of

'our' vehicles are likely to be affected by this process and any vehicle in possession

of a valid logbook (VSNSC) does not require to follow it.

Rest assured that FBHVC will continue to monitor

these consultations to ensure that any action that may follow does not

adversely affect our movement. In the meantime continue to attach furry dice to

your vehicles without fear that cameras will record your crime and impose a

penalty for non-reporting!

MOT Test Procedures

We continue to receive comments that the computerised

MOT test procedures have given rise to new restrictions or removal of data,

such as obsolete makes/models. In most cases DVLA is blamed for these problems.

While their database is not perfect, upon examination we have found that the

problems are caused by lack of relevant technical information on the VOSA database

or a test examiner's unfamiliarity with the newly installed system, e.g.

ability to cancel/re-input incorrect data. We repeat our advice to double-check

the vehicle description and numbers to ensure that what the tester records is

on the V5C. If not correct, make sure the changes are done before your test.

Much adverse comment has come from the so-called

'abolition' of the free re-test. That animal never really existed but grew from

a practice that, at best, was customer-service related but more likely was

'tester-effort' biased. VOSA has recognised there is a genuine requirement for

rectification of modest faults without incurring a full fee and is taking steps

to put this in place. It is up to each Testing Station to decide the level of

fee, up to a maximum, in this category.

We repeat our advice that owners should undertake a

preMoT inspection of their vehicles rather than continue the habit of many of

using the MoT test to tell you what servicing work is needed. This could become

an expensive habit if not corrected!

Renewal of Car Tax

(VED)

Finally, a piece of welcome and up-to-date news. It

is now possible to renew your VIED disc through the Electronic Vehicle

Licencing (EVL) facility that has just been announced following a successful

pilot programme in several areas.

This can be done via the telephone at 0870 850 4444

or by logging on to www.direct.gov.uk/taxdisc. All keepers of vehicles less than three years old can use

ELV while those subject to an MoT test will need to have a computerised MoT

certificate. (It is anticipated that all MoT testing stations will be

operational by the end of March 2006 so all licensed vehicles should be able to

use ELV by 2007). There is no need to present paper insurance or MoT

certificates as the process is handled electronically; the VED disc will be

despatched by post and received within 3-4 days.

Access to a phone or computer will enable -a

keeper to apply for a VED wherever they may be, at home or abroad, 24 hours per

day and seven days per week. SORN may also be declared electronically so the

new ELV procedures should answer the vast majority of concerns we have heard

from members who travel both frequently or extensively. As always, we welcome

feedback from members who have had experience of ELV whether or not it is

favourable.

DRIVE IT DAY - 23 APRIL

FBHVC urges all owners of licensed historic vehicles

to use them on 23 April - every year. This will be a truly national annual

event and one that all enthusiasts can take part in,

wherever they live. It's absolutely free of entry forms, fees and red

tape.

It's not necessary for owners to go to a show or to

take part in an event, FBHVC just wants owners to get their vehicles out so

they can be seen by the public. If the vehicle is suitable, it could be used

instead of modern transport for daily activity. Owners could use them to go to

work take a trip to the seaside, enjoy a day out in the country, visit a

stately home or just go shopping.

For those with unlicensed, older, larger or slower

vehicles for which such use would be impossible, impractical or inappropriate,

owners could at least get them out and park them on the drive where they can be

seen.

FBHVC exists to uphold the freedom to use old

vehicles. Drive It Day is part of an ongoing campaign to raise public

awareness of the historic vehicle movement. After all, Tony Beadle (the

committee member who came up with the idea) asks, what's the point in fighting

for a freedom if we don't make the best possible use of it?

OLYMPIC PHASES

Most Rochdale owners will be familiar with the fact that

there were two major variations with the Olympic, the phase 1 and the phase 2.

Some will even have heard of a phase 1. and assume that this was an

intermediate model. This is a bit misleading as such a model never officially

existed. I will attempt to explain my understanding of the models produced and

the major differences between them. Of course, the phase 1 was never

officially called a phase 1 until the phase 2 had been introduced.

The first production shells were noticeably different from

subsequent Phase 1s in the following respects. The bonnet was smaller, being

only 30.5" at its widest point compared to 34.5". The shape of the rear edge

of the bonnet was also different, being more or less straight rather than

following the curve of the windscreen. This left no space for a heater intake

opening. The photo in the Motor Road Test indicates this quite clearly. On

the early shells the front sub-frame is also different in that the B series

engine is mounted from the inner wing panels with a bonded in tubular framework

and not from the sub-frame. A number of the internal mouldings are slightly

different. Very few of these early shells were produced, but at least five are

known to have survived. Three versions were available for Riley/Wolseley,

Morris Minor or Ford 10 components.

After the factory fire it was necessary to remake the

moulds and I have always assumed that it was at this point that point that the

changes were made to produce the phase 1 shell that most of us are familiar

with. The front sub-frame will vary slightly, depending on whether it was supplied

for Riley/Wolseley or Morris Minor components, as the steering rack is

different. Initially, all engine mounts were from the inner wing panels,

although at some point fairly early on the B series engines were mounted from

the front sub-frame.

Two different kits were available, the Riley version at

£670 and the Morris Minor version at £598. The Ford 105E engine was an option

with the Minor kit at no extra cost. Incidentally, when the 105E engine was

supplied the mountings from the inner wing panels were retained. This was no

doubt due to the fact that the Ford mountings were half way along the side of

the block and not at the front as with the BMC engines.

During the latter part of 1962 a revised version of the

Olympic was under development. This was introduced to the public at the Racing

Car Show in January 1963. Substantial modifications were made, to the extent

that very few major components or mouldings are interchangeable. However, as

the external silhouette remained the same some part panel mouldings can be used

to repair either phases.

The most noticeable of these changes externally was a

larger bonnet, opening rear hatch and cut away rear panel to allow mounting of

a spare wheel underneath. The changes however went much further and consisted

of a revised front sub-frame to suit the Triumph based suspension, fully ducted

radiator and open transmission tunnel rather than the full length undertray of

the phase 1. The rear suspension also changed to tapering box section trailing

arms and full width panhard rod to locate the rear axle. Internally the

mouldings were modified with a new dashboard and thinner doors giving increased

interior width. The two small rear seats also disappeared being replaced by a

flatter load area.

The Phase 2 with 1500cc Ford engine sold for £755, with the

GT engine a £40 extra. Initially the phase 1 kit could still be obtained as a

cheaper alternative. However, there were increasing supply problems with BMC

components and before long the phase 1 would only be available as a

body/chassis unit at a cost of £256.

Whilst the phase 2 was under development one or two phase

1s were either supplied or retro fitted with an opening hatch by the factory.

This process has continued in latter years and a number of phase 1 shells have

been subsequently converted.

By the mid 1960s Harry and Frank had obviously decided that

the Phase 1 moulds were not good enough to use. Hence if a customer

particularly wanted to use Morris or Riley components he would be supplied with

what was essentially a Phase 2 shell, with Phase 2 rear suspension, but

different front sub-frame to take the BMC components. The cost for this option

was £271. By this time production of the Olympic had slowed down to a trickle

and the literature was not reprinted, but merely amended by hand. The cost for

the phase 2 kit had increased to £780 and the Ford 1500 engine replaced by the

1600 cross flow engine.

The above is my own understanding of the Olympic variations

produced by Rochdale Motor Panels, but I stand to be corrected if anyone knows

differently.

Derek Bentley

PART No.

RS 1

|

Material:

Polyurethane

Application: Ph 1

Panhard rod axle end; Top shock absorber

Ph

2 Panhard rod body end; Rear shock absorber lower; Anti-roll bar link

upper

|

|

PART No. RS 2

Application: Ph 2 front suspension pivot

PART No. RS 3

Material:

Polyurethane with removable stainless steel sleeve

Application: Ph 2

Panhard rod axle end

|

Copyright © Rochdale

Owners Club

Last Update

Nigel

Nigel

The trouble is, when we read articles about flows we often

read about Laminar flow. This is where the flow is nice and stable and meets

certain conditions (more on this later) and laminar flow is most often

described as being layered (these are the laminas per se). With respect to

intake ports this means that layer closest to the port wall is stationary (the

sub-laminar layer). The next layer is moving quite slowly due to friction with

the sub laminar layer and the next slightly faster again and the next one the

same again etc.

The trouble is, when we read articles about flows we often

read about Laminar flow. This is where the flow is nice and stable and meets

certain conditions (more on this later) and laminar flow is most often

described as being layered (these are the laminas per se). With respect to

intake ports this means that layer closest to the port wall is stationary (the

sub-laminar layer). The next layer is moving quite slowly due to friction with

the sub laminar layer and the next slightly faster again and the next one the

same again etc.  But what we must also

acknowledge is that this is a nice neat explanation of laminar port flow is

often misleading or worse factually incorrect! What we find in an intake port